8 Reasons Why CMMS Software is Better than Spreadsheets

A Wake-up Call for Maintenance Managers

During the past four decades, businesses have witnessed many advances in their operations, primarily driven by technological innovations and evolving management practices. One significant development is the widespread adoption of cloud computing, enabling organizations to streamline processes, enhance collaboration, and achieve greater flexibility in managing data and applications. Additionally, the rise of data analytics has empowered businesses to make more informed decisions by extracting valuable insights from vast amounts of information. Automation and artificial intelligence have revolutionized routine tasks, increasing efficiency and reducing errors.

At times, all of these changes may seem overwhelming. Add to the mix of frustration are heightened competition within industry and business sectors and economic challenges. Both place pressure on a company’s bottom line. In this fast-paced business environment, staying ahead of the curve is more than an aspiration; it's become necessary. For this reason, having the right tools to meet your increasing and ever-changing needs are essential. What may have worked well in the past is no longer sufficient.

If you’re in the maintenance world, one tool that may weigh you down is relying on spreadsheets to manage your company’s maintenance management needs. For decades, spreadsheets were the go-to solution for maintenance leaders, but not anymore. Today’s fast-paced business environment requires solutions that deliver real time data, automated workflows, collaboration and mobility. This is where Computerized Maintenance Management Software (CMMS) comes into play.

Here, we'll explore eight compelling reasons why CMMS software is not just a necessity, but also a game-changing technology for businesses wanting to optimize their operations and increase their profit margins.

1. The Spreadsheet Struggle: They’re No Longer Cutting it!

Businesses often start with spreadsheets because they are a cost-effective way to manage maintenance tasks. Spreadsheets were adopted by businesses small and large. Only the largest, most complex operations would adopt CMMS software. Today, this is not the case, businesses, small and large are embracing this maintenance software due to lower costs, ease of use and implementation and mobility. Maintenance departments are transitioning from spreadsheets to CMMS software because:

- They need specialized features tailored for maintenance workflows, making it challenging to efficiently track equipment maintenance, schedule preventive tasks, and manage work orders.

- They are prone to human error due to the necessity of manual inputs such as a misplaced decimal point or an improperly transcribed number.

- Limitations on collaboration and communication because spreadsheets don’t offer extensive information.

On the other hand, CMMS is explicitly designed for maintenance management, offering dedicated modules for asset tracking, work order management, and preventive maintenance scheduling. CMMS streamlines processes, enhances collaboration, and provides real-time insights, making it a more robust solution for organizations with intricate maintenance requirements.

While spreadsheets once offered a simple maintenance management solution, this is no longer true for many businesses. The limitations of spreadsheets slowed maintenance operations as businesses matured, expanded, and adopted new technologies.

2. CMMS Centralized Information Hub: A Quantum Leap Beyond Spreadsheets

CMMS acts as a centralized hub for all your company’s maintenance-related data. From work orders to equipment history, everything is organized and easily accessible. There is no longer a need to spend time searching through multiple files to find what you need.

Unlike spreadsheets, a CMMS provides a dedicated platform to streamline and optimize maintenance processes. A centralized CMMS makes it possible to conduct comprehensive asset tracking, work orders, and maintenance history in one organized system. This enhances accessibility, collaboration, and real-time visibility for maintenance teams. With features such as automated scheduling, preventive maintenance, and robust reporting tools, a CMMS offers efficiency gains that surpass spreadsheet-based systems' manual and often error-prone nature. The ability to manage assets, track work orders, and analyze maintenance data in a centralized hub contributes to improved decision-making, resource allocation, and overall operational effectiveness.

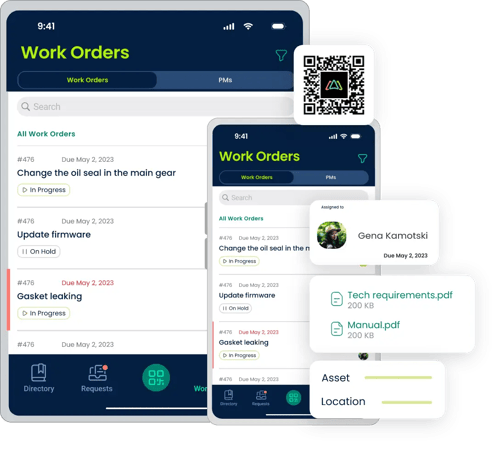

3. The Mobile Advantage: A Tool That Spreadsheets Don’t Have

CMMS’s features don’t stop at a desktop; they make maintenance management possible on the go and wherever maintenance team members may be. With a mobile app, maintenance managers can oversee operations, approve work orders, and check inventory levels – all from any mobile device.

More specifically, a CMMS mobile app offers many advantages over traditional spreadsheets in managing maintenance operations. Unlike spreadsheets, CMMS mobile apps, like desktop software, provide a centralized platform for tracking and scheduling maintenance tasks, equipment inspections, and work orders. The mobile app enables real-time data entry and updates, improving communication and collaboration among maintenance teams. It also allows technicians to access critical information on the go, streamlining workflow efficiency.

Many CMMS mobile apps have the added feature of capturing images, accessing files (manuals, SOPs, contracts), scanning QR codes, GPS tracking and push notifications, providing a more comprehensive view of maintenance activities. These additional capabilities from CMMS mobile apps optimizes workflows, improving response and completion times.

In summary, CMMS mobile apps offer a more efficient, accessible, and integrated maintenance management solution than traditional spreadsheets.

4. Improved Efficiency: Spreadsheets can be a Drag on Time, Energy, and Money

Unlike spreadsheets, CMMS is designed to streamline and enhance maintenance efficiency. CMMSs’ centralized approach eliminates the need for manual data entry and reduces the likelihood of errors, ensuring accurate and up-to-date records. Additionally, CMMS automates routine tasks such as scheduling preventive maintenance, generating work orders, and tracking inventory levels. CMMS facilitates better communication among maintenance teams, allowing real-time collaboration and data sharing.

Cost saving is an essential factor when it comes to efficiency. After all, time is money. A CMMS saves time and money by streamlining maintenance processes and reducing downtime. In the long run, significant cost savings make a CMMS a sound investment for business owners looking to optimize their operations.

5. Real-time Visibility: Something Spreadsheets Lack

One of the glaring limitations of spreadsheets is their static nature. CMMS, on the other hand, provides real-time visibility into an organization’s assets and maintenance activities. A CMMS offers several ways maintenance managers can evaluate the current status of every piece of equipment. The following are a few ways they can do this:

- A CMMS can continuously monitor equipment performance using sensors, IoT devices, and data connectivity.

- Real-time data on key parameters such as temperature, pressure, vibration, and other relevant metrics are collected and transmitted to the CMMS.

- Maintenance managers can access this information through a centralized dashboard, providing instant insights into the health and status of equipment.

- Alerts and notifications can be set up to flag potential issues or deviations from normal operating conditions, enabling proactive maintenance interventions.

All of this and more happens at the touch of a button. Maintenance managers can get up-to-the-minute insights on any number of maintenance-related issues.

This real-time visibility facilitates a quick response to emerging problems. It empowers maintenance managers to make data-driven decisions, optimize preventive maintenance schedules, and enhance equipment reliability and performance.

6. Proactive Maintenance: No Comparison with Spreadsheets

References to preventive maintenance have been made previously. Let’s look more closely at preventive or proactive maintenance, a much sought-after CMMS feature by most maintenance managers.

Unlike spreadsheets, CMMS provides a centralized and organized platform to automate the scheduling process, ensuring that tasks are carried out at optimal time intervals, reducing the risk of equipment failures and downtime. It can also predict when equipment will likely fail, helping maintenance managers schedule maintenance before a breakdown occurs. This translates to fewer unexpected downtimes and more efficient operations.

Furthermore, a CMMS can quickly generate reports and analyses, providing insights into equipment performance and maintenance trends. These automation and analytical capabilities are beyond a spreadsheet’s capabilities, mainly because spreadsheets are reactive and must wait for the user's inputs. Ultimately, these CMMS capabilities make it a more efficient and comprehensive solution for preventive maintenance management.

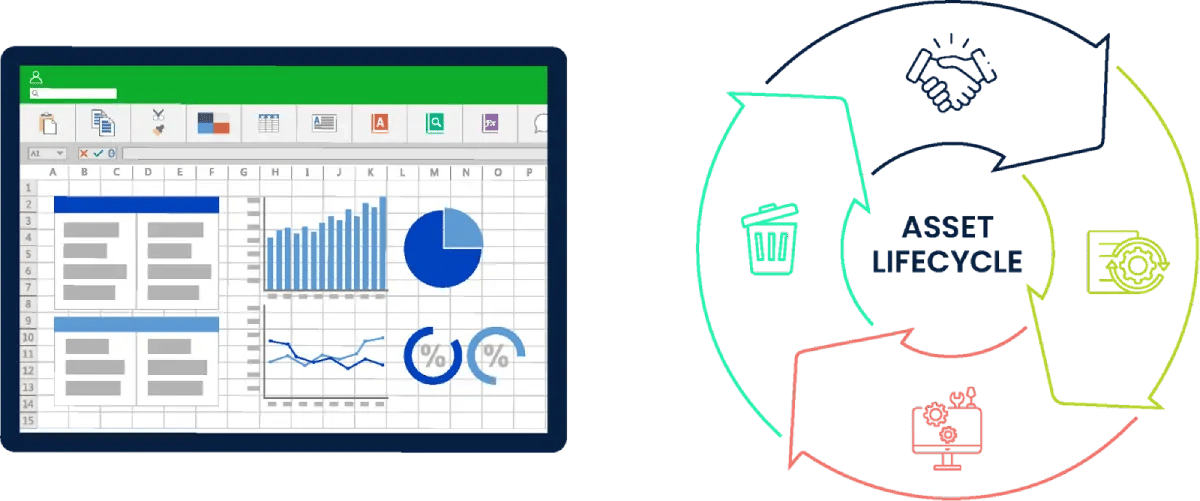

7. Asset Lifecycle Management: Beyond the Scope of Spreadsheets

Spreadsheets pale in comparison to CMMS software when it comes to keeping up with the complexity of managing assets throughout their lifecycle. CMMS excels in asset lifecycle management because it provides a comprehensive view of each asset's journey – from acquisition to retirement. A CMMS can optimize an organization’s assets and help maintenance managers make strategic decisions based on asset performance over time.

8. Compliance Assurance: Spreadsheets Don’t Cut it

CMMS offers advantages over spreadsheets for businesses that operate in highly regulated industries and must demonstrate compliance during audits. Most CMMS software provide detailed audit trails of all maintenance activities that are logged. The systems provide structured databases for efficient organization and retrieval of relevant information, ensuring that all regulatory requirements are documented and easily accessible. Additionally, CMMS software often includes automated features such as task scheduling, preventive maintenance alerts, and real-time monitoring, streamlining compliance processes and reducing the likelihood of errors or oversights.

Spreadsheets lack the capabilities described above. Without them, manual errors, version control challenges, and difficulty in maintaining a comprehensive audit trail are real risks.

Conclusion: A Look to the Future

The future of business operations is dynamic, efficient, and fueled by technology. By embracing CMMS software, you're not just upgrading your maintenance management but future-proofing your business. The days of spreadsheet struggles are becoming a thing of the past because maintenance leaders recognize their limitations.

In a world of constant change, embracing innovation is the key to staying relevant. For a growing number of organizations, CMMS software is considered the cutting-edge solution for maintenance management. From organizing work orders to tracking inventory and scheduling preventive maintenance, the all-encompassing solution can streamline maintenance management operations within its robust software system. CMMS software is much more than a maintenance tool; it's a strategic asset for businesses striving to thrive in a competitive landscape.

TABLE OF CONTENTS

Keep Reading

Ever find yourself checking into a luxury hotel and expecting a relaxing stay, only to find a ...

11 Apr 2025

Organizations are witnessing swift changes in the business environment and confronting a ...

8 Apr 2025

Last month, news outlets and the entire internet was abuzz with the return of NASA astronauts ...

3 Apr 2025

What comes first - CMMS or predictive maintenance? If your answer is either, it is correct. ...

28 Mar 2025

Artificial intelligence (AI) talk has become commonplace. Today, engaging in business-focused ...

27 Mar 2025

Imagine a world where machines predict, diagnose, and fix their issues before they fail. This ...

25 Mar 2025

A facility maintenance plan is at the core of a facility’s operations. This organized ...

21 Mar 2025

Think of managing your maintenance operations like managing a championship sports team. Just ...

21 Mar 2025

The maintenance sector is battling a severe talent shortage that threatens to undermine ...

7 Mar 2025

Manufacturing maintenance is the backbone of industrial efficiency, ensuring machines run ...

5 Mar 2025

No one likes playing a guessing game when equipment breaks down. Yet, maintenance teams often ...

4 Mar 2025

The size of the preventive maintenance software market is discussed in millions of dollars, ...

4 Mar 2025

The organizational structure and corporate hierarchy vary from company to company. Large ...

28 Feb 2025

Maintenance procedures are essential for ensuring the longevity and reliability of machinery ...

21 Feb 2025

Sustainability is no longer just a buzzword; it's a critical component of corporate social ...

20 Feb 2025

A Computerized Maintenance Management System (CMMS) relies on accurate, well-organized data ...

18 Feb 2025

In an era where technology drives operational efficiency, Computerized Maintenance Management ...

14 Feb 2025

A Computerized Maintenance Management System (CMMS) is a key component of modern maintenance ...

13 Feb 2025

Introduction Maintenance management is the foundation of maintenance operations in industries ...

11 Feb 2025

Introduction A Computerized Maintenance Management System (CMMS) is software designed to help ...

7 Feb 2025