Click Maint vs. LLumin - CMMS Solutions Serving Different Operational Needs

The choice of a Computerized Maintenance Management System (CMMS) can significantly impact operational efficiency and long-term success of your business. Different industries have unique needs, making it essential to select a CMMS that aligns with specific operational goals. For manufacturing, where precision and uptime are key factors, a CMMS tailored to these demands can make all the difference. Conversely, smaller businesses across various industries may require a more versatile solution that offers quick deployment and ease of use.

This comparison between LLumin and Click Maint CMMS aims to guide organizations in making informed decisions by highlighting the strengths of each platform. LLumin is known for its strong focus on the manufacturing sector, offering features like Overall Equipment Effectiveness (OEE) reporting to optimize production processes. Click Maint, on the other hand, empowers small to mid-sized businesses with its simplicity, adaptability, and affordability. Rather than criticizing either platform, this article will emphasize where each CMMS software shines, ensuring a positive and constructive comparison. By understanding the unique advantages and potential of both LLumin and Click Maint, you can make a choice that best suits your business operational needs and growth aspirations.

LLumin CMMS - Optimizing Manufacturing Processes

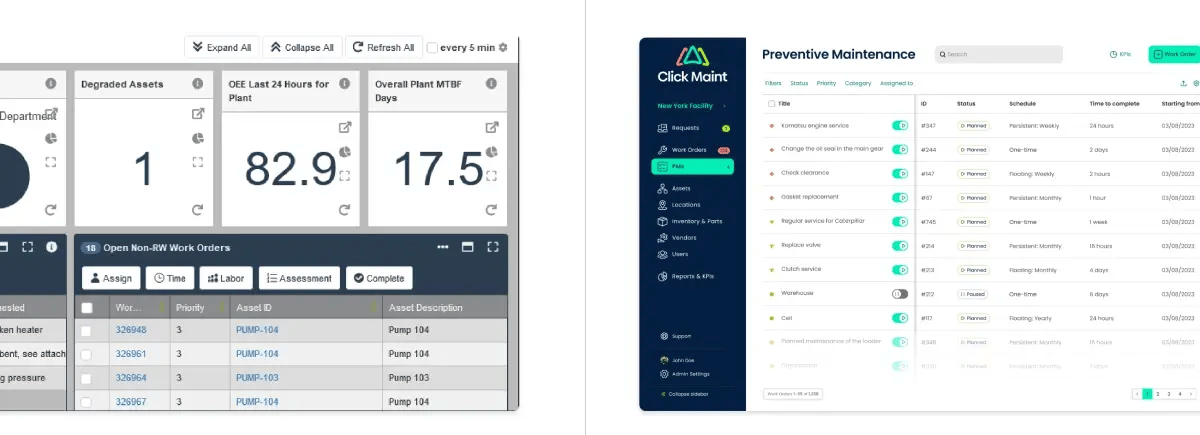

LLumin CMMS is uniquely designed to meet the specific demands of the manufacturing industry, where precision and efficiency are important. The platform is built to support the complex operational requirements of manufacturers, offering tools that help streamline processes, reduce downtime, and enhance productivity. LLumin’s focus on manufacturing is evident in its features, which are geared toward maximizing the performance of machinery and ensuring that production lines operate smoothly.

One of the standout features of LLumin CMMS is its Overall Equipment Effectiveness (OEE) reporting capabilities. OEE is a vital metric for manufacturers, measuring the percentage of manufacturing time that is productive. LLumin’s OEE reporting provides real-time insights into the availability, performance, and quality of production, enabling manufacturers to optimize production processes. OEE is a metric that identifies losses, benchmarks progress, and improves the productivity of manufacturing equipment and machinery. It is calculated using the following formula: OEE = Availability × Performance × Quality.

Target Audience

The primary users of LLumin CMMS are professionals within the manufacturing and industrial sectors. These users include maintenance managers, plant operators, and production supervisors who need robust tools to manage the intricacies of a manufacturing environment. LLumin is designed to meet their needs, providing them with the data and tools necessary to maintain high levels of operational efficiency and equipment reliability.

Key Strengths

LLumin’s strengths lie in its specialized features that cater specifically to the manufacturing and food and beverage processing industries. This software is unique in that it goes beyond maintenance management and extends its capabilities to help manufacturers manage production processes as well. LLumin has all the capabilities necessary for managing work orders, PMs, inspection, downtime, and inventory but goes further by empowering users to manage production quality. The platform’s OEE reporting is a significant asset, offering real-time data that supports proactive decision-making. LLumin also excels in process optimization, providing tools that help manufacturers streamline operations and reduce waste. Unique features like predictive maintenance capabilities set LLumin apart, allowing users to anticipate equipment failures and prevent costly downtime.

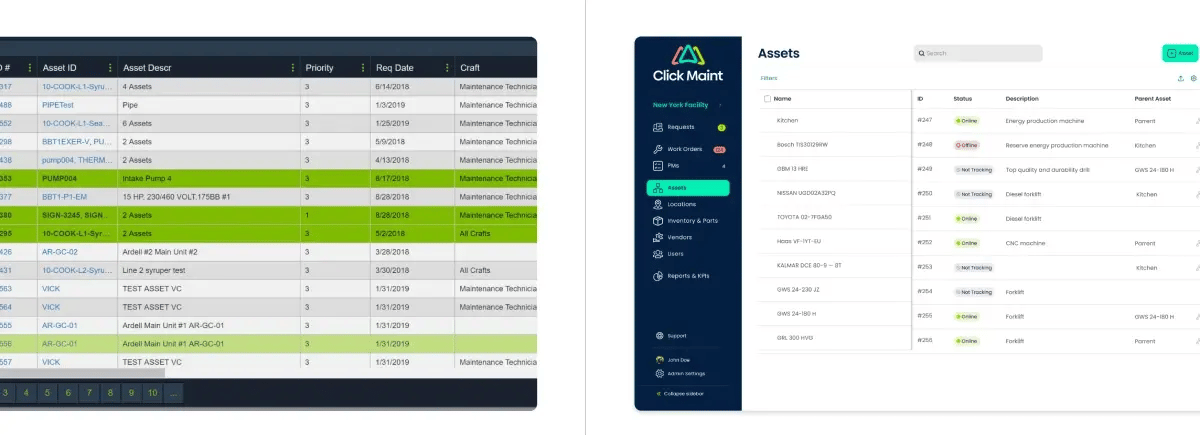

Click Maint CMMS - Empowering Small to Mid-Sized Businesses

Click Maint CMMS is a versatile solution specifically designed to meet the needs of small to mid-sized businesses across a wide range of industries. Unlike platforms that focus on a single sector, Click Maint offers flexibility that makes it suitable for businesses in facilities management, healthcare, hospitality, retail, and more. Its adaptability allows it to be customized to fit the unique requirements of various operations, whether it's managing maintenance schedules in a small manufacturing plant or overseeing equipment in a healthcare facility. This versatility is one of Click Maint’s core strengths, enabling it to cater to a broad spectrum of business needs without sacrificing functionality or performance. The platform is designed with simplicity in mind, ensuring that even businesses without dedicated IT teams can easily implement and benefit from its features.

Target Audience

The primary users of Click Maint CMMS are professionals in small manufacturing plants, facilities management, maintenance teams in smaller enterprises, and business owners who need a reliable, easy-to-use solution for managing their maintenance operations. Whether you’re a small manufacturing company looking to streamline your processes or a retail chain seeking to maintain equipment efficiently, Click Maint is designed to provide the necessary tools and support.

Key Strengths

Click Maint excels in several areas, particularly in its quick deployment, ease of use, and cost-effectiveness. These attributes make it an attractive option for smaller businesses that need a powerful CMMS without the complexity and expense of more extensive systems. Its user-friendly interface and straightforward setup process mean that companies can start using Click Maint with minimal CMMS training and upfront costs. The platform’s adaptability also stands out, as it can be tailored to meet the specific needs of different businesses. Whether it’s integrating with existing systems or scaling as the business grows, Click Maint offers the flexibility that small to mid-sized enterprises require.

Reputation and Industry Recognition

Both LLumin and Click Maint have earned strong reputations within their respective markets. LLumin is recognized for its specialization in manufacturing, while Click Maint is celebrated for its versatility and focus on empowering small businesses. Click Maint has received industry recognition for its user-friendly design and cost-effectiveness, making it a preferred choice for companies that need a reliable and adaptable CMMS. While LLumin’s reputation is strengthened by its advanced features for manufacturing and production management, Click Maint is praised for its simplicity and broad application across diverse industries.

Feature Comparison

Core features

|

Features |

Click Maint CMMS |

LLumin CMMS |

|---|---|---|

|

Work Order Management |

Comprehensive, with easy tracking and reporting features. |

Strong, with advanced tracking and integration capabilities. |

|

Advanced scheduling with automation, customizable to business needs. |

Impressive scheduling tools, integrated with OEE reporting for optimized workflows. |

|

|

Asset Management |

Detailed asset tracking, configurable forms, downtime tracking, and history reports. |

Comprehensive, especially for complex manufacturing environments. |

|

Efficient tracking with low stock alerts. |

Praised for its comprehensive view and ability to manage warehouse operations effectively. |

|

|

Mobile Access |

Fully mobile-compatible, with a user-friendly interface for on-the-go maintenance. |

Limited but functional, primarily focused on key maintenance tasks. |

|

Customization |

Limited, best suited for straightforward operations. |

Extensive, allowing deep customization to fit manufacturing processes. |

|

Integration Capabilities |

Limited, focusing on core functionalities; requires IT support. |

Strong, integrates well with ERP systems and other enterprise software. |

|

Vendor & Supplier Management |

Simplified management tools for tracking vendor performance. |

Advanced, with detailed tracking and integration with financial systems. |

User Experience

|

Click Maint CMMS |

LLumin CMMS |

|

|---|---|---|

|

User Interface (UI) |

Intuitive, modern interface designed to minimize the learning curve. |

Functional, more complex due to its depth, suited for users familiar with CMMS. |

|

Onboarding |

Quick process with dedicated customer support for smooth CMMS implementation. |

Comprehensive but may require more time due to feature depth, with strong remote support. |

|

Overall User Satisfaction |

High, due to ease of use, flexibility, and responsive support. |

High, especially in manufacturing sectors; praised for its support and adaptability. |

|

Pricing |

Affordable, starting at $35/user/month; low onboarding costs. |

Subscription model, starting at $45/user/month; more expensive but justifiable for its advanced features. |

Support and Security

|

Click Maint CMMS |

LLumin CMMS |

|

|---|---|---|

|

Customer Support |

Dedicated team with a focus on rapid issue resolution and customer success. |

Excellent, with a strong reputation for responsiveness and remote assistance. |

|

Security Measures |

Robust, including data encryption and regular security updates. |

Strong, with comprehensive data protection and integration with existing security protocols. |

Specialized Features

|

Click Maint CMMS |

LLumin CMMS |

|

|---|---|---|

|

Accessibility |

Mobile CMMS Access: Strong focus on mobile accessibility, enabling maintenance on the go. |

OEE Reporting: A specialized feature, a key feature for manufacturing efficiency that provides real-time insights. |

|

Unique Advantage |

Cost-Effectiveness: Ideal for businesses looking for affordable, effective CMMS. |

Process Optimization: Advanced tools for streamlining manufacturing processes, reducing downtime, tracking quality of production. |

In-Depth Feature Review

Both Click Maint and LLumin offer many core features, but their strengths cater to different needs. Click Maint excels in work order management and preventive maintenance with customizable scheduling and automation options suited to various business needs. Its asset management is also strong, featuring detailed tracking with configurable forms and maintenance history reports. Conversely, LLumin thrives in complex manufacturing environments, where its work order management and preventive maintenance tools integrate seamlessly with Overall equipment effectiveness (OEE) reporting for optimized workflows. LLumin’s inventory management is particularly noteworthy for its comprehensive view and effective warehouse management. User experience differs between the platforms; Click Maint focuses on simplicity with an intuitive interface, quick onboarding, and high user satisfaction, while LLumin’s more complex system is highly regarded within manufacturing due to its depth and specialization, supported by excellent remote assistance. Both platforms offer strong support and security, with Click Maint emphasizing rapid issue resolution and secure data encryption, and LLumin provides excellent customer support and comprehensive security that integrates well with existing systems. In scalability and integration, LLumin is designed for large manufacturing operations with extensive integration capabilities, whereas Click Maint is better suited for small to mid-sized businesses, offering essential functions with API and third-party middleware options. Specialized features also highlight the differences between the platforms; Click Maint’s mobile access is vital for smaller businesses, while LLumin’s OEE reporting provides detailed real-time insights for manufacturing efficiency. In conclusion, Click Maint is ideal for small to mid-sized businesses seeking an easy-to-use, cost-effective CMMS, while LLumin is better for larger manufacturing operations requiring advanced features and customization.

How Click Maint Stands Out

Current Advantages

Click Maint CMMS distinguishes itself through its quick deployment, simplicity, and affordability. Designed specifically for small to mid-sized businesses, Click Maint offers a user-friendly interface that minimizes the learning curve, allowing organizations to implement and start using the system with minimal disruption. Its affordability makes it an attractive option for cost-conscious businesses, providing comprehensive maintenance management features without the hefty price tag. The platform’s simplicity does not compromise functionality, making it easy for teams to manage work orders, track assets, and perform preventive maintenance efficiently.

Future Potential

Looking ahead, Click Maint is prepared for growth with planned developments that promise to enhance its value further. Future updates include the development of differentiated functionalities that will set it apart from competitors, such as advanced preventive maintenance and inspection management and unique integrations. The platform also aims to expand its integration capabilities with popular office software like Office 365, ensuring seamless workflow across various tools. Additionally, Click Maint plans to enhance key features like inventory management and purchase orders, making it stronger and more adaptable to larger enterprises. These advancements will continue to solidify Click Maint’s position as a top choice for small to mid-sized businesses.

Common Advantages

LLumin and Click Maint excel in several key areas, making them strong contenders in the CMMS market. One of their most notable shared strengths is their customer support. Both platforms are highly praised for their responsiveness and dedication to helping users, ensuring smooth onboarding and ongoing satisfaction. In terms of data management, both Click Maint and LLumin provide robust solutions that allow businesses to efficiently track and analyze maintenance data, leading to more informed decision-making and optimized operations. User satisfaction is another common advantage, with both platforms offering intuitive interfaces and valuable features that cater to their target audiences. Whether it’s LLumin’s depth in manufacturing or Click Maint’s versatility across industries, users consistently report high levels of satisfaction due to the ease of use, reliable performance, and comprehensive support provided by both systems.

Conclusion

In summary, both LLumin and Click Maint offer Solid CMMS solutions tailored to different industry needs. LLumin shines in manufacturing, particularly with its advanced OEE reporting and deep customization options. Meanwhile, Click Maint stands out for its versatility, quick deployment, and affordability, making it ideal for small to mid-sized businesses across various industries.

For businesses seeking a cost-effective maintenance management solution that delivers quick value with minimal disruption, Click Maint is a compelling choice. Its user-friendly interface and comprehensive features cater to a wide range of sectors, from manufacturing to education and healthcare. We recommend Click Maint for organizations looking for a versatile and reliable CMMS that balances performance with affordability.

Take the next step towards optimizing your maintenance operations by choosing Click Maint —

where diverse usability meets fair pricing.

TABLE OF CONTENTS

Keep Reading

Ever find yourself checking into a luxury hotel and expecting a relaxing stay, only to find a ...

11 Apr 2025

Organizations are witnessing swift changes in the business environment and confronting a ...

8 Apr 2025

Last month, news outlets and the entire internet was abuzz with the return of NASA astronauts ...

3 Apr 2025

What comes first - CMMS or predictive maintenance? If your answer is either, it is correct. ...

28 Mar 2025

Artificial intelligence (AI) talk has become commonplace. Today, engaging in business-focused ...

27 Mar 2025

Imagine a world where machines predict, diagnose, and fix their issues before they fail. This ...

25 Mar 2025

A facility maintenance plan is at the core of a facility’s operations. This organized ...

21 Mar 2025

Think of managing your maintenance operations like managing a championship sports team. Just ...

21 Mar 2025

The maintenance sector is battling a severe talent shortage that threatens to undermine ...

7 Mar 2025

Manufacturing maintenance is the backbone of industrial efficiency, ensuring machines run ...

5 Mar 2025

No one likes playing a guessing game when equipment breaks down. Yet, maintenance teams often ...

4 Mar 2025

The size of the preventive maintenance software market is discussed in millions of dollars, ...

4 Mar 2025

The organizational structure and corporate hierarchy vary from company to company. Large ...

28 Feb 2025

Maintenance procedures are essential for ensuring the longevity and reliability of machinery ...

21 Feb 2025

Sustainability is no longer just a buzzword; it's a critical component of corporate social ...

20 Feb 2025

A Computerized Maintenance Management System (CMMS) relies on accurate, well-organized data ...

18 Feb 2025

In an era where technology drives operational efficiency, Computerized Maintenance Management ...

14 Feb 2025

A Computerized Maintenance Management System (CMMS) is a key component of modern maintenance ...

13 Feb 2025

Introduction Maintenance management is the foundation of maintenance operations in industries ...

11 Feb 2025

Introduction A Computerized Maintenance Management System (CMMS) is software designed to help ...

7 Feb 2025