Top CMMS Features that Maintenance Managers & Technicians Look for

A CMMS is a powerful tool that makes it possible for maintenance teams to collaborate better and increase facility efficiency. However, not all CMMS software is created equal and maintenance managers and technicians now have options when choosing one that can meet their specific requirements.

Since each organization has different workflows and processes, maintenance managers and technicians in the maintenance department are best positioned to identify the features needed to streamline their work and improve productivity. Therefore, it is critical that business owners consider team leaders’ opinions and insights when selecting a CMMS system.

By taking into account the experience of the actual software users, it's possible to ensure that the selected software is tailored to the requirements of the maintenance department, resulting in effective implementation and better results.

What do Maintenance Managers Look for in a CMMS?

CMMS software can improve the productivity of maintenance managers and increase the accuracy of various tasks. However, even the most feature-rich software may only get optimally utilized if it can be customized to meet an organization's specific requirements. Here are some top CMMS software features maintenance managers need to extract maximum benefit:

1. Customization

Customizability is one of the top requirements of maintenance managers in a CMMS. They should be able to customize the system to track and manage the various assets. The software should also make it possible for them to create tailored workflow templates, reporting formats, and maintenance schedules to meet their requirements.

2. Integration

Integration with other software is an important feature crucial to the success of a CMMS system. Maintenance managers often rely on multiple tools, including PLCs and SCADA systems, to monitor and control equipment. A sound CMMS system should seamlessly integrate with other existing systems, allowing maintenance managers to access integrated data and improve visibility into the various maintenance activities.

3. Scalability

Every organization seeks growth and this is why scalability is a crucial factor for maintenance managers to consider. As a company grows, the number of assets and equipment requiring maintenance will also increase. Therefore, the CMMS must be capable of handling an increasing number of equipment, locations, and technicians.

4. Cost-effectiveness

According to a survey, the leading cause of unscheduled downtime within respondents’ facilities was identified as aging equipment (40%), followed by mechanical failure (24%) and finally by operator error (12%).

In this regard, it is important to note that a CMMS with preventive maintenance scheduling and real-time performance tracking can help avoid unexpected downtime due to equipment failure. Ultimately, this will lead to better efficiency and cost optimization.

Scalability in software is also related to cost-effectiveness, which refers to the ability of the system to provide better value for money spent. A cost-effective CMMS software should not only be able to reduce equipment downtime through intuitive scheduling and insights, but also offer flexible pricing models based on the requirements of a company.

5. Upgrades and Support

Maintenance managers should also consider the cost of upgrades and the level of support and training offered for the software. A good CMMS provider should offer comprehensive training for maintenance managers to use the system effectively. Ongoing technical support and software updates are also crucial to keep the system current and running efficiently.

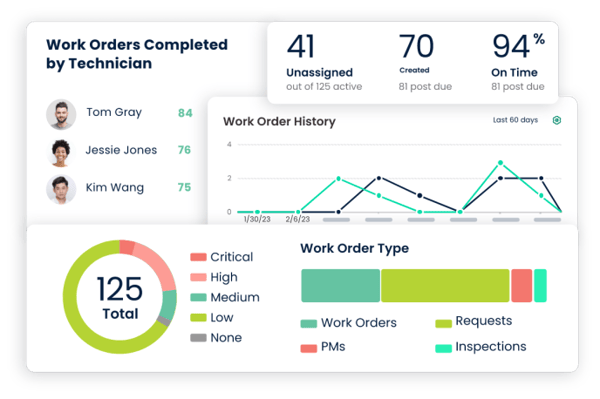

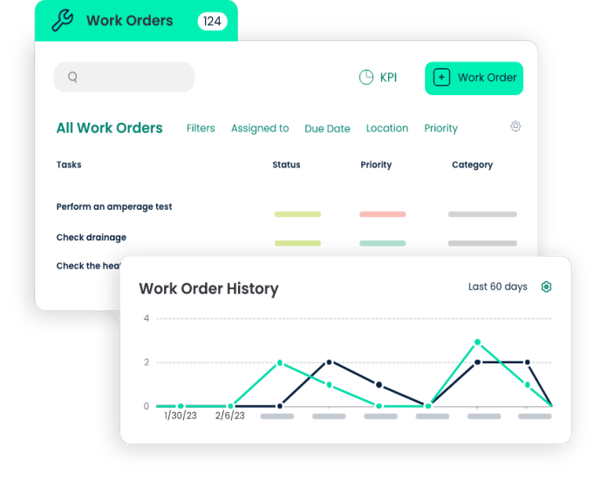

6. Reporting

Compiling maintenance KPIs manually is tedious and run the risk of errors. A good CMMS software can pull and collate data about various aspects of maintenance operations and provide reporting templates to help maintenance managers make sense of that data. It should also allow managers to customize the KPIs and set reporting schedules to ensure that all the critical information reaches them promptly.

What CMMS Software Features do Maintenance Pros look for?

Maintenance technicians are the people who actually carry out routine maintenance and repair activities in any organization. A CMMS software could assist in added productivity, provided it's tailored to the unique requirements of their job. Some of the essential features needed by maintenance technicians in CMMS software include:

1. Accessibility and Mobility

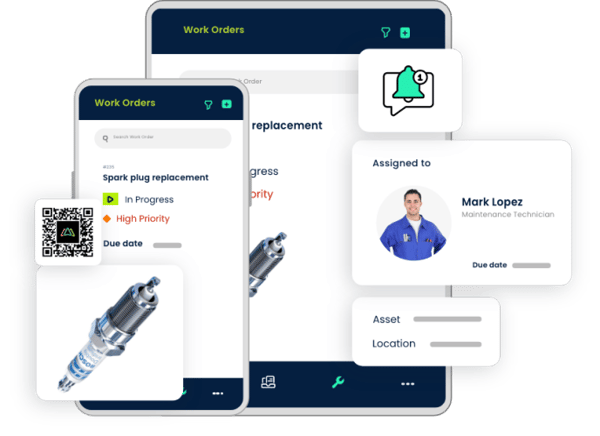

Maintenance technicians are often on the move, especially when working on assets across multiple facilities. A cloud-based CMMS software has the capability of giving technicians access to information on the go. They can access servicing records for various assets anywhere, and at any time, receive and modify work orders online, and update the status of their tasks in real time without requiring a laptop or being restricted to any single location.

2. User-Friendly Interface

Besides accessibility, a user-friendly interface could be beneficial for busy technicians. It can reduce onboarding time and increase efficiency through intuitive dashboards that make accessing important information and collaborating with peers easier.

3. Accuracy and Reliability of Data

Maintenance technicians are responsible for the upkeep of multiple assets. CMMS software makes their task easy by keeping a record of asset information and incident history that can be accessed at the touch of a few buttons. Some software systems also use sophisticated sensors to provide real-time updates about asset conditions. Such updates can help technicians identify minor fixes that can help prevent significant repairs or breakdowns in future. A CMMS with accurate and up-to-date data can also reduce the risk of duplicate work orders and missed tasks.

4. Mobile Application

A mobile-based CMMS software could be convenient in the field by allowing technicians to access work orders on the go. Additionally, it can provide real-time updates on work orders and give access to asset information on the go, without any requirement of going through historical documents or paperwork. A mobile application can also reduce the administrative tasks associated with record-keeping.

5. Easy Communication and Collaboration

Easy communication and collaboration features are essential in CMMS software for faster decision-making and effective issue resolution. Real-time communication between various stakeholders eliminates procedural bottlenecks and improves teamwork. It also reduces confusion and duplication of work.

Maximizing the Benefits of CMMS for an Organization: The Way Forward

Maintenance managers and technicians are critical in selecting and implementing CMMS software. Being the actual software users, their experience and insights can be valuable when comparing CMMS software features for your organization.

Different organizations have different workflows and processes in place. A CMMS must be flexible and intuitive enough to fit these ongoing workflows. Additionally, the maintenance department must remain flexible and open in its approach. Therefore, looking beyond features and considering an organization's work culture is essential when looking for the right fit.

As technology evolves, new features and workflows are continually being developed. It's essential to be open enough to experiment with these new features and find ways to optimize your existing workflows. Maintenance managers and technicians must be open to change and willing to adopt new technology to maximize the benefits of the software.

Ultimately, finding the right CMMS requires maintenance managers, technicians, and other stakeholders in a company to work together. The needs of the organization and the requirements of maintenance managers and technicians should be considered together to select a system capable of integrating with existing workflows and improving them.

TABLE OF CONTENTS

Keep Reading

Ever find yourself checking into a luxury hotel and expecting a relaxing stay, only to find a ...

11 Apr 2025

Organizations are witnessing swift changes in the business environment and confronting a ...

8 Apr 2025

Last month, news outlets and the entire internet was abuzz with the return of NASA astronauts ...

3 Apr 2025

What comes first - CMMS or predictive maintenance? If your answer is either, it is correct. ...

28 Mar 2025

Artificial intelligence (AI) talk has become commonplace. Today, engaging in business-focused ...

27 Mar 2025

Imagine a world where machines predict, diagnose, and fix their issues before they fail. This ...

25 Mar 2025

A facility maintenance plan is at the core of a facility’s operations. This organized ...

21 Mar 2025

Think of managing your maintenance operations like managing a championship sports team. Just ...

21 Mar 2025

The maintenance sector is battling a severe talent shortage that threatens to undermine ...

7 Mar 2025

Manufacturing maintenance is the backbone of industrial efficiency, ensuring machines run ...

5 Mar 2025

No one likes playing a guessing game when equipment breaks down. Yet, maintenance teams often ...

4 Mar 2025

The size of the preventive maintenance software market is discussed in millions of dollars, ...

4 Mar 2025

The organizational structure and corporate hierarchy vary from company to company. Large ...

28 Feb 2025

Maintenance procedures are essential for ensuring the longevity and reliability of machinery ...

21 Feb 2025

Sustainability is no longer just a buzzword; it's a critical component of corporate social ...

20 Feb 2025

A Computerized Maintenance Management System (CMMS) relies on accurate, well-organized data ...

18 Feb 2025

In an era where technology drives operational efficiency, Computerized Maintenance Management ...

14 Feb 2025

A Computerized Maintenance Management System (CMMS) is a key component of modern maintenance ...

13 Feb 2025

Introduction Maintenance management is the foundation of maintenance operations in industries ...

11 Feb 2025

Introduction A Computerized Maintenance Management System (CMMS) is software designed to help ...

7 Feb 2025