CMMS vs. CAFM: Exploring the Differences and Synergies

Maintenance and facility management functions are not just about preserving assets and workspaces but also about improving efficiency, reducing downtime, and ensuring the safety and satisfaction of employees and customers.

CMMS software is the go-to solution for those seeking to maintain the longevity and reliability of their assets, including heavy machinery, building and mobile equipment, and critical systems. It's the driving force behind ensuring that industries like manufacturing, healthcare, and utilities function smoothly and efficiently.

On the other hand, CAFM (Computer-Aided Facility Management) is a software solution for those striving to create intelligent and well-organized office spaces and facilities that prioritize both productivity and comfort. It's predominantly embraced by corporate offices, real estate management, and anyone aiming to harmonize physical spaces and workforce optimization.

This article explores both CMMS and CAFM, their differences, and overlapping features and characteristics. Understanding these distinctions and connections will enable organizations to make informed choices about which software is best suited to their needs and how to integrate these systems for data-driven decision-making.

Understanding CMMS

Key Features and Functionalities of CMMS

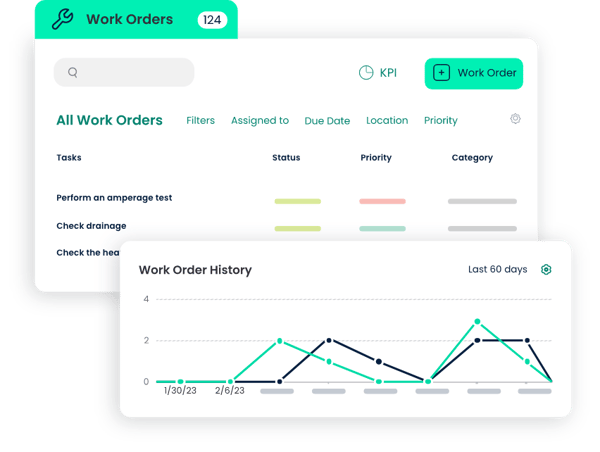

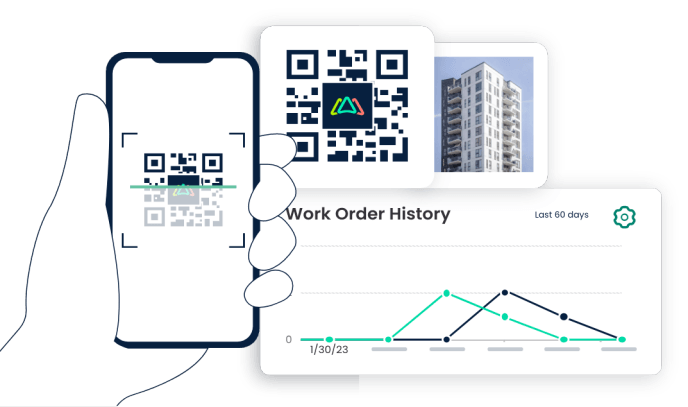

Work Order Management

CMMS provides a structured system for creating, assigning, and tracking work orders. This feature ensures that maintenance tasks are organized and executed in a timely manner, reducing downtime and minimizing disruptions.

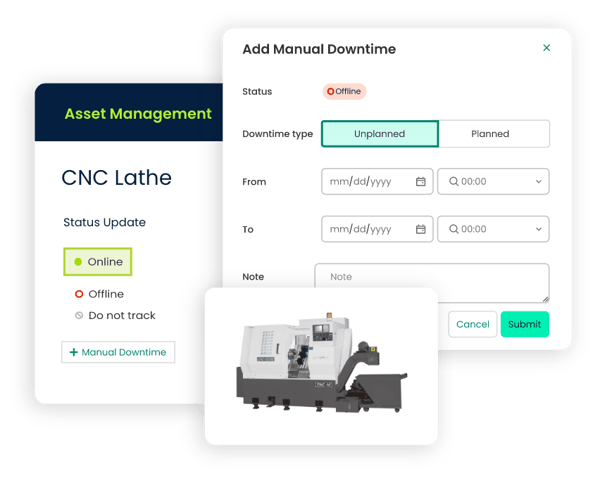

Asset Management

CMMS enables users to track and manage assets. It keeps a detailed record of assets, including their maintenance history, current status, and lifecycle data. This aids in making informed decisions regarding repairs, replacements, or upgrades.

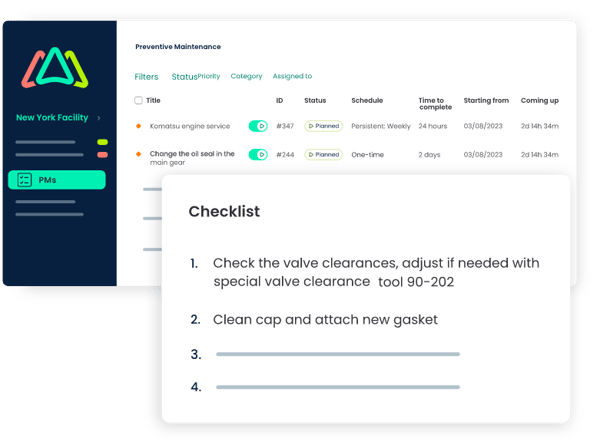

Preventive Maintenance

CMMS enables users to schedule, document, and manage preventive maintenance tasks and activities. This proactive approach helps prevent unexpected breakdowns, extends the life of equipment, and maintains facilities and assets.

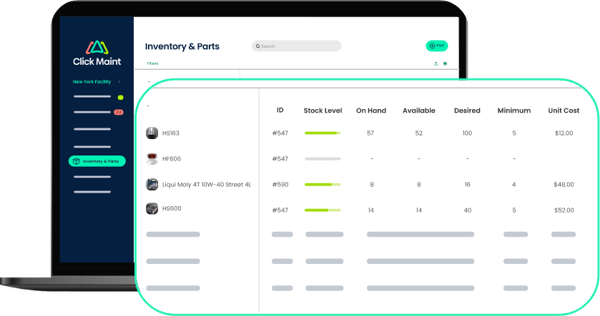

Inventory Management

CMMS includes inventory management features that track spare parts, consumables, and maintenance supplies. It helps in managing stock levels, reordering when necessary, and reducing excess inventory costs.

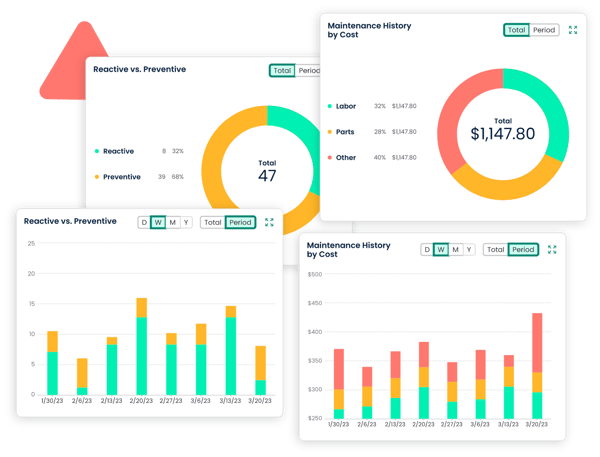

Reporting and Analytics

CMMS generates detailed reports and offers data analytics tools to provide insights into maintenance operations. Users can monitor maintenance KPIs, identify trends, and make data-driven decisions to improve efficiency and reduce costs.

Industries that Benefit from CMMS

CMMS software is highly versatile and offers benefits across a wide range of industries, including but not limited to:

- Manufacturing: Keeping production lines running efficiently.

- Healthcare: Ensuring the reliability of critical medical equipment.

- Utilities: Managing infrastructure for consistent service delivery.

- Hospitality: Maintaining facilities for a positive guest experience.

Benefits of Using a CMMS

- Improved Equipment Reliability: By implementing scheduled maintenance and tracking asset performance, CMMS enhances the reliability of equipment, reducing unexpected breakdowns and associated downtime.

- Increased Maintenance Efficiency: CMMS streamlines maintenance processes, leading to quicker response times, efficient resource allocation, and improved workforce productivity.

- Cost Reduction: Proactive maintenance and optimized inventory management lower operational costs by reducing emergency repairs and minimizing downtime.

- Compliance and Regulatory Adherence: CMMS helps organizations adhere to industry regulations and safety standards by ensuring that maintenance tasks are carried out in a compliant manner, reducing the risk of non-compliance fines and penalties.

Understanding CAFM

Key Features and Functionalities of CAFM

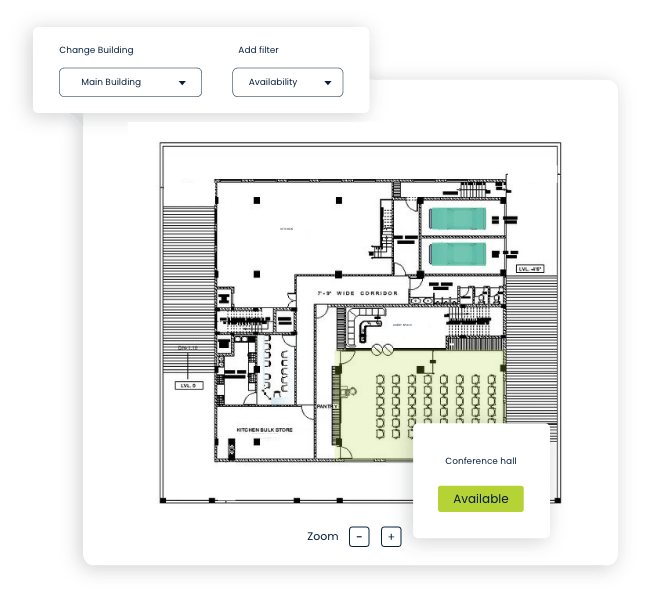

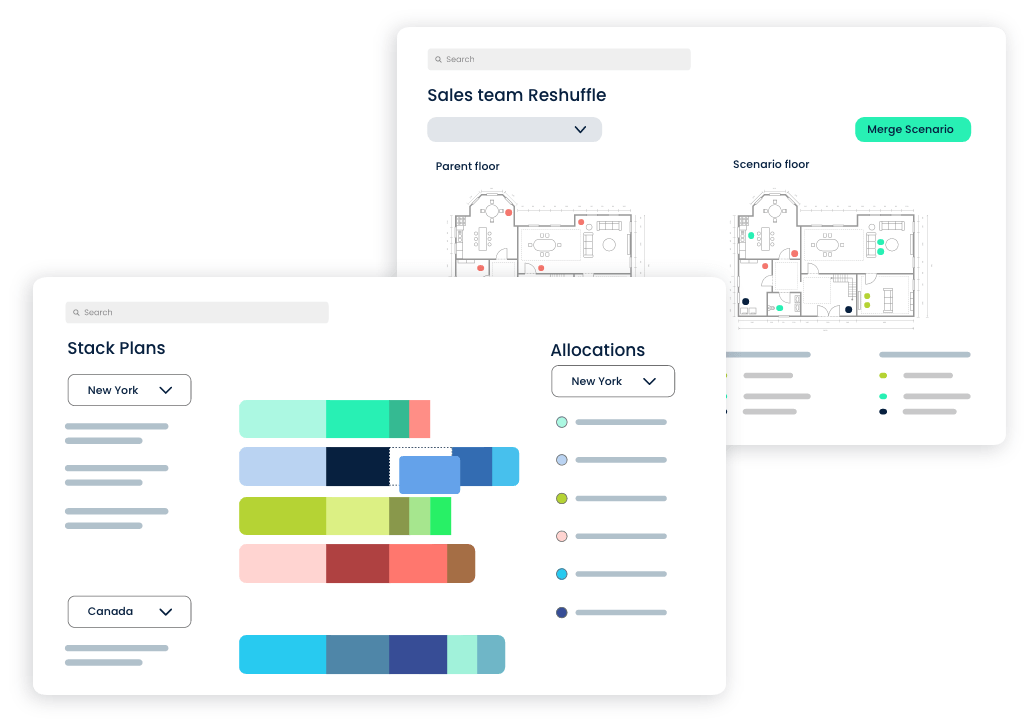

Space Planning and Management

CAFM excels in space management, providing tools to design, allocate, and monitor the usage of physical spaces within an organization. It offers detailed floor plans, occupancy data, and space utilization analytics.

Workplace Optimization

CAFM supports workplace optimization by facilitating desk booking, resource scheduling, and room reservations. This enhances workforce productivity by ensuring that the right spaces are available when needed.

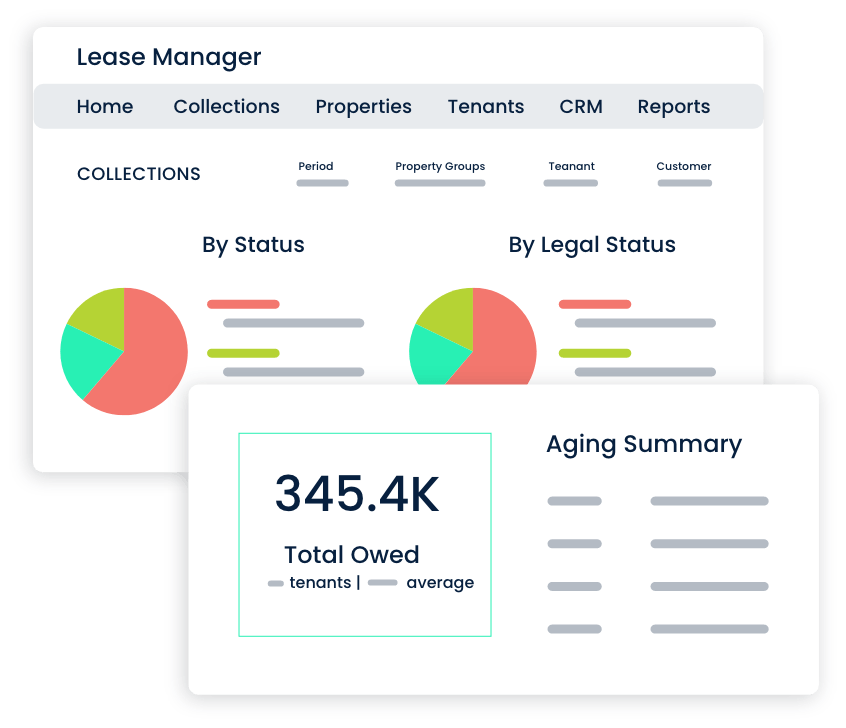

Lease Management

CAFM software assists in managing lease agreements, tracking critical dates, and ensuring compliance with lease terms. This functionality is important for real estate management and cost control.

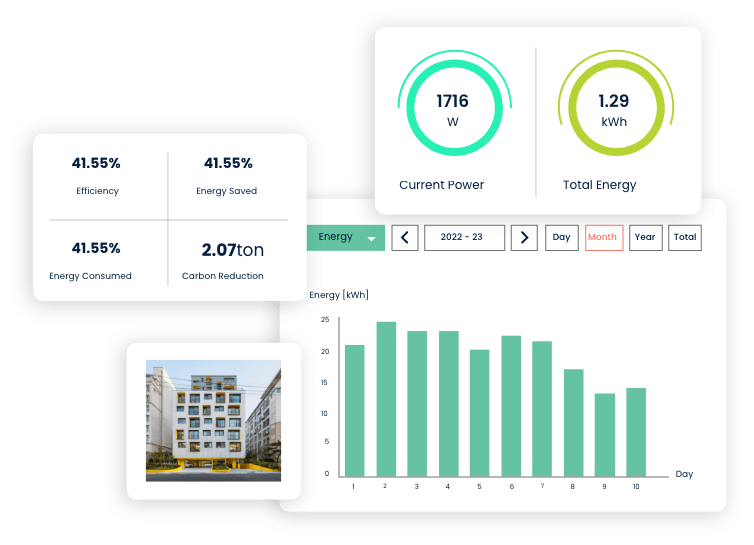

Energy Management

CAFM incorporates energy management features to monitor and optimize energy consumption within facilities. It helps in identifying opportunities for energy savings and sustainability initiatives.

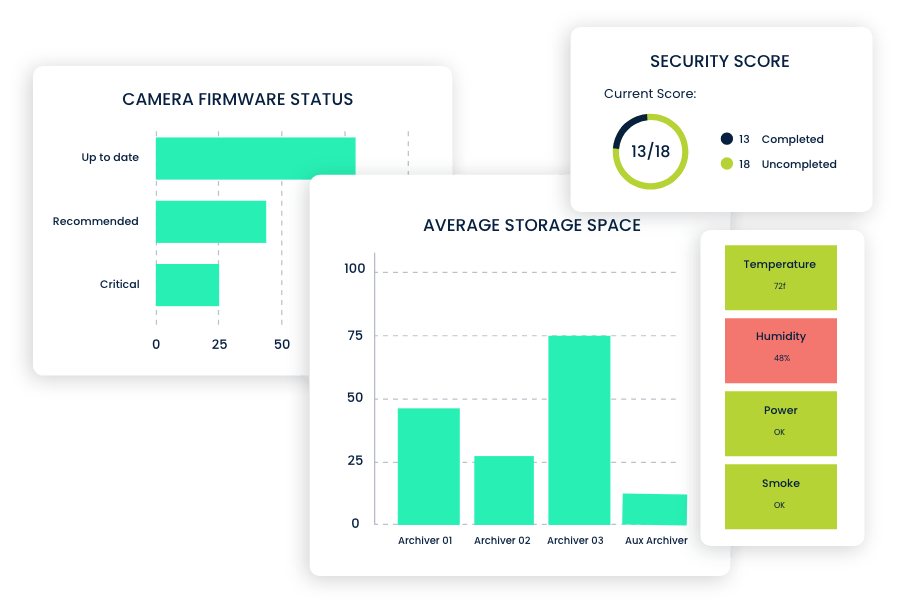

Security and Access Control

CAFM systems integrate security and access control, enabling organizations to manage permissions, monitor security incidents, and maintain a safe and secure work environment.

Industries that Benefit from CAFM

CAFM software is valuable in a variety of industries, including:

- Corporate Offices: Enhancing workspace design, resource allocation, and employee well-being.

- Real Estate Management: Streamlining property management, lease tracking, and space optimization.

- Government Facilities: Supporting efficient use of public spaces and compliance with regulations.

- Educational Institutions: Optimizing classroom and facility utilization for improved learning environments.

Benefits of Using CAFM

- Efficient Space Utilization: CAFM enables organizations to maximize space usage, reducing underutilized areas and promoting efficient office layouts. This results in cost savings and the ability to accommodate growth without expanding physical space.

- Improved Workplace Productivity: By providing employees with well-organized workspaces and the tools to book meeting rooms and resources, CAFM boosts workforce productivity and job satisfaction.

- Better Lease Management and Cost Control: CAFM helps organizations effectively manage lease agreements, reducing the risk of non-compliance and minimizing unnecessary expenses.

- Improved Security and Safety: Through integrated security and access control features, CAFM enhances workplace safety and ensures that only authorized personnel can access restricted areas, promoting a secure working environment.

Key Similarities between CMMS and CAFM

While CMMS (Computerized Maintenance Management System) and CAFM (Computer-Aided Facility Management) serve distinct purposes in the realms of maintenance and facility management, they share several common features that are integral to their functionality.

- Reporting and Analytics Capabilities: Both CMMS and CAFM systems offer robust reporting and analytics features. Users can generate detailed reports, visualize data trends, and gain valuable insights into the performance and efficiency of their maintenance and facility management operations. These capabilities enable data-driven decision-making, helping organizations continuously improve their processes.

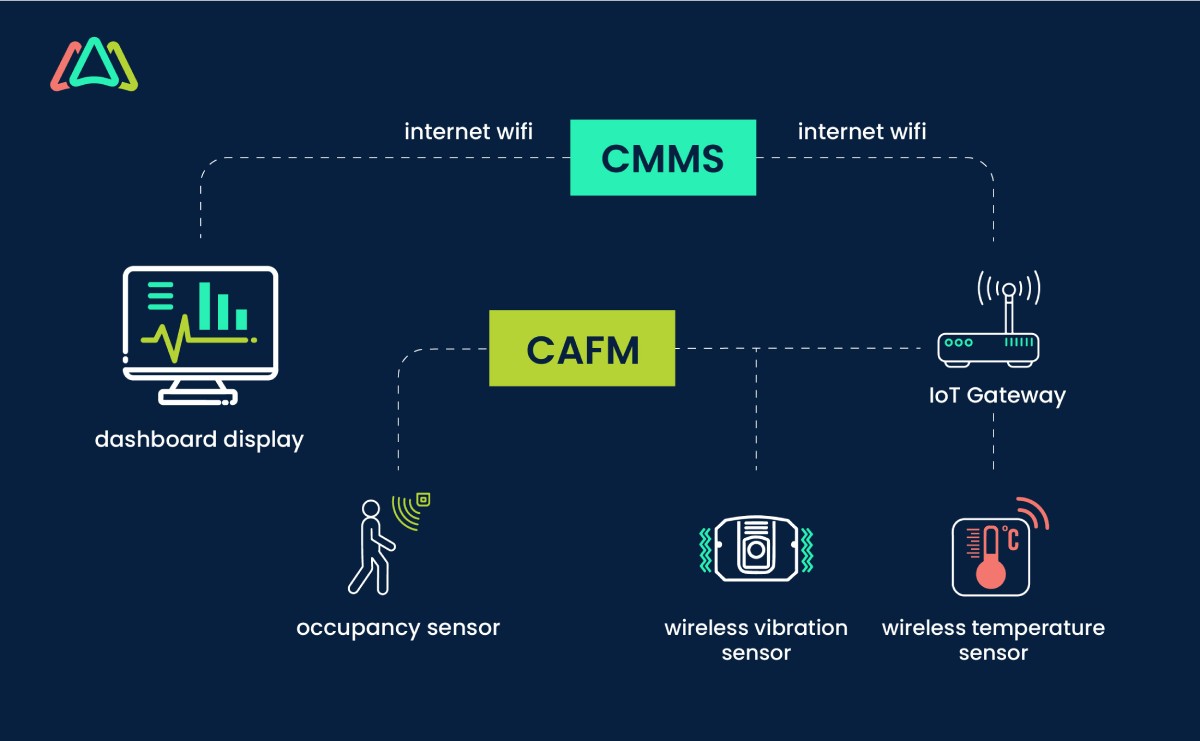

- Integration with IoT Sensors for Data Collection: The integration of Internet of Things (IoT) sensors is a shared characteristic of CMMS and CAFM. These sensors collect real-time data from various sources, such as equipment, occupancy, and environmental sensors. This data is then utilized to monitor asset health, energy consumption, space utilization, and other critical factors. Integrating IoT data enhances the accuracy and timeliness of maintenance and facility decisions.

- Mobile Access for On-the-Go Management: Facilities and maintenance operations require fast responsiveness, flexibility, and mobility. Both CMMS and CAFM systems recognize this need by offering mobile access capabilities. Maintenance technicians, facility managers, and other stakeholders can access the software from their mobile devices, allowing them to stay connected and manage tasks on the go. Mobile access enhances response times, simplifies work order management, and fosters better communication within teams.

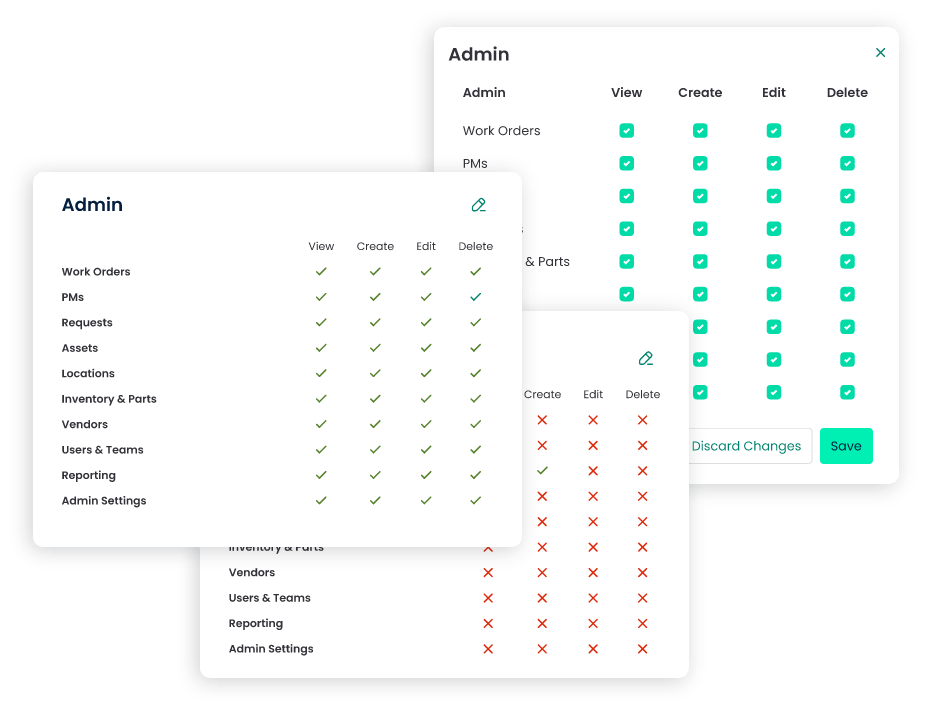

- Role-Based Access Control to Ensure Data Security: Security is a top priority for both CMMS and CAFM. To safeguard sensitive data, these systems employ role-based access control mechanisms. This means that users are granted access to specific features and information based on their roles and responsibilities within the organization. This ensures that confidential data is protected and users can only access information relevant to their tasks.

While most CAFM (Computer-Aided Facility Management) systems include modules and features for work orders and requests, it's essential to recognize that maintenance isn't typically at the core of CAFM's focus. These modules serve as valuable add-ons to the facility-centric features of CAFM, enabling users to efficiently manage maintenance tasks within the broader context of facility operations. It's important to note that the inclusion of maintenance features in CAFM doesn't make these systems exclusive to maintenance operations; rather, they offer a comprehensive approach that caters to both maintenance and facility management needs. This flexibility allows organizations to create well-balanced work environments, optimizing both space utilization and asset reliability while responding to maintenance requirements efficiently.

Key Differences between CMMS and CAFM

Focus and Purpose

CMMS: Maintenance-centric

CMMS is primarily centered around maintenance operations and preserving equipment and assets. Its core purpose is to ensure the reliability and efficiency of machinery, systems, and infrastructure. CMMS is instrumental in industries where downtime can result in significant losses and disruptions.

CAFM: Facility-centric

In contrast, CAFM, or Computer-Aided Facility Management, revolves around optimizing physical spaces, workplace planning, and the overall functionality of facilities. CAFM is designed to create productive and comfortable environments for employees, balancing factors like space allocation, resource scheduling, and user satisfaction. It is particularly valuable in office spaces and real estate management.

Core Functionality

CMMS: Asset and Maintenance Management

The core functionality of CMMS is asset management and maintenance. It excels at tracking and maintaining equipment, managing work orders, and implementing preventive maintenance strategies. Its main objective is to maximize the reliability and lifespan of assets and minimize downtime.

CAFM: Space and Facility Management

CAFM's primary function is to manage physical spaces and facilities efficiently. It provides tools for space planning, resource allocation, and lease management. CAFM focuses on creating an ideal workplace environment, optimizing space utilization, and enhancing the overall workplace experience.

User Base

CMMS: Primarily Used by Maintenance Teams

CMMS software is primarily intended for use by maintenance teams, technicians, and asset managers. Its user base typically consists of individuals responsible for equipment maintenance, repair, and reliability.

CAFM: Utilized by Facility Managers and Workplace Planners

CAFM is designed for facility managers, workplace planners, and those responsible for optimizing office spaces. It caters to professionals focused on workspace design, resource allocation, and user satisfaction.

Key Features CMMS: Work Order Management, Preventive Maintenance

Key features of CMMS include work order management for maintenance tasks and preventive maintenance scheduling to minimize breakdowns and equipment failures.

CAFM: Space Allocation, Lease Management

CAFM offers features like space allocation for efficient workspace utilization and lease management to ensure compliance with rental agreements and cost control.

Industries and Use Cases

CMMS: Manufacturing, Healthcare, Utilities

CMMS is typically found in industries where equipment reliability is critical, such as manufacturing for production equipment, healthcare for medical devices, and utilities for infrastructure maintenance.

CAFM: Corporate Offices, Real Estate Management

CAFM is prevalent in corporate offices where workplace optimization is essential and in real estate management to manage properties and leases effectively.

Understanding these key differences is important for organizations when selecting the appropriate software solution for their specific needs, whether it's optimizing maintenance operations with CMMS or creating efficient, user-friendly office spaces with CAFM.

Are you interested in learning more about how an easy to use CMMS solution can help your organisation streamline its maintenance processes and lower costs?

Integration and Data Flow

Data Integration Between CMMS and CAFM

- Identifying the Data that Should Reside in CMMS: Data that should reside within a CMMS include information about equipment, its maintenance history, and the spare parts inventory. This data is critical for maintenance teams to effectively plan and execute equipment upkeep, ensuring reliability and minimizing downtime.

- Identifying the Data that Should Reside in CAFM: In the case of CAFM, the focus shifts to data related to space allocation, occupancy, and lease agreements. CAFM systems thrive on data pertaining to the utilization of physical spaces, ensuring optimal layouts and adherence to lease terms. This information is invaluable for facility managers and workplace planners.

Data Flow for Better Decision Making

- Importance of Data Exchange Between CMMS and CAFM: The synergy between CMMS and CAFM is heightened through data exchange. Real-time, accurate data flows between these systems, allowing organizations to make informed decisions. Maintenance and facility management are interdependent, and harmonizing data enhances operational efficiency.

- How Data from CMMS Informs Space Utilization Decisions in CAFM: Real-time data from CMMS, such as information on equipment downtime and maintenance schedules, can directly impact space utilization decisions in CAFM. For example, if a critical piece of equipment is due for maintenance, CAFM can temporarily reallocate the adjacent workspace to minimize disruption.

- How Occupancy Data from CAFM Influences Maintenance Prioritization in CMMS: CAFM's occupancy data, which indicates how office spaces are utilized, can inform maintenance prioritization in CMMS. If certain spaces experience high occupancy, maintenance schedules can be adjusted to minimize inconvenience during peak usage periods, ensuring a smooth workflow.

Choosing the Right Solution for Your Needs

Factors to Consider When Selecting between CMMS and CAFM

Choosing between CMMS and CAFM is a pivotal decision that depends on several key factors. It's important to consider:

- The nature of your organization's core operations: Is it more asset-centric or facility-centric?

- Industry-specific needs and compliance requirements.

- The scale of your organization and the complexity of your maintenance and facility management demands.

- The existing technology infrastructure and systems in place.

- Budget constraints and the cost of implementation and maintenance.

- The size and expertise of your maintenance and facility management teams.

Assessing Your Organization's Specific Requirements for Data Integration

When evaluating your organization's specific requirements, consider:

- Which data elements are critical for seamless decision-making and where they should reside.

- The extent to which real-time data exchange can enhance your maintenance and facility management operations.

- The level of compatibility between the selected CMMS and CAFM systems.

- The potential for customizations and software extensions to meet unique integration needs.

- Data security and privacy concerns, especially if sensitive data is involved.

The choice between CMMS and CAFM isn't just about software selection; it's about aligning your choice with the core objectives and needs of your organization. The decision should be informed by the nature of your operations, industry-specific requirements, budget considerations, and the size and expertise of your teams. Selecting the right solution is only the first step; it's the harmonious integration and the synergy between them that truly elevates your maintenance and facility management practices.

TABLE OF CONTENTS

Keep Reading

Ever find yourself checking into a luxury hotel and expecting a relaxing stay, only to find a ...

11 Apr 2025

Organizations are witnessing swift changes in the business environment and confronting a ...

8 Apr 2025

Last month, news outlets and the entire internet was abuzz with the return of NASA astronauts ...

3 Apr 2025

What comes first - CMMS or predictive maintenance? If your answer is either, it is correct. ...

28 Mar 2025

Artificial intelligence (AI) talk has become commonplace. Today, engaging in business-focused ...

27 Mar 2025

Imagine a world where machines predict, diagnose, and fix their issues before they fail. This ...

25 Mar 2025

A facility maintenance plan is at the core of a facility’s operations. This organized ...

21 Mar 2025

Think of managing your maintenance operations like managing a championship sports team. Just ...

21 Mar 2025

The maintenance sector is battling a severe talent shortage that threatens to undermine ...

7 Mar 2025

Manufacturing maintenance is the backbone of industrial efficiency, ensuring machines run ...

5 Mar 2025

No one likes playing a guessing game when equipment breaks down. Yet, maintenance teams often ...

4 Mar 2025

The size of the preventive maintenance software market is discussed in millions of dollars, ...

4 Mar 2025

The organizational structure and corporate hierarchy vary from company to company. Large ...

28 Feb 2025

Maintenance procedures are essential for ensuring the longevity and reliability of machinery ...

21 Feb 2025

Sustainability is no longer just a buzzword; it's a critical component of corporate social ...

20 Feb 2025

A Computerized Maintenance Management System (CMMS) relies on accurate, well-organized data ...

18 Feb 2025

In an era where technology drives operational efficiency, Computerized Maintenance Management ...

14 Feb 2025

A Computerized Maintenance Management System (CMMS) is a key component of modern maintenance ...

13 Feb 2025

Introduction Maintenance management is the foundation of maintenance operations in industries ...

11 Feb 2025

Introduction A Computerized Maintenance Management System (CMMS) is software designed to help ...

7 Feb 2025