Understanding the Key Differences: CMMS vs. EAM

In today’s economy and competitive landscape, organizations are putting more pressure on their leaders to produce more, with fewer resources. This is one of the biggest challenges for maintenance and asset managers. They are under constant pressure to solve the puzzle of how to increase productivity for their departments while reducing costs. Maintenance and asset management leaders look toward technology to achieve these outcomes.

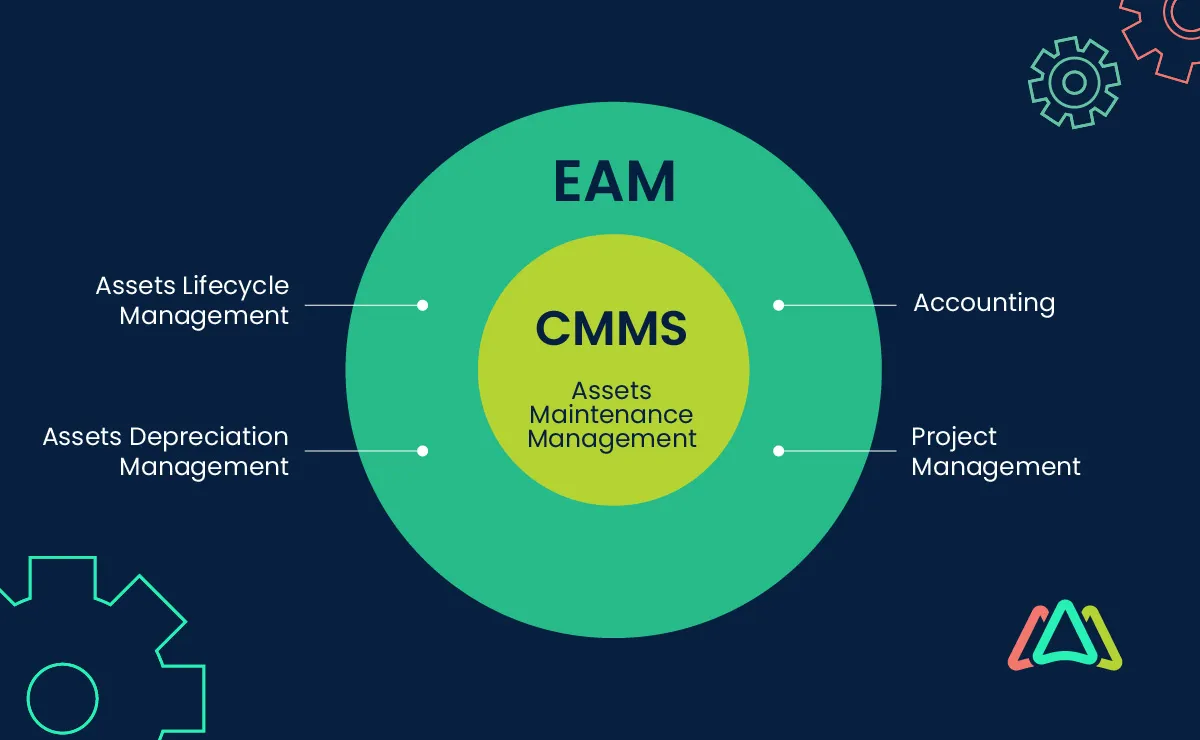

In the ever-evolving landscape of equipment management, two types of software have emerged as frontrunners in helping organizations maintain, track, and manage their assets efficiently: Computerized Maintenance Management Systems (CMMS) and Enterprise Asset Management (EAM) systems. While many would agree that both CMMS and EAM are effective solutions for asset and maintenance management, fundamental differences exist between them. If you’re an asset or maintenance manager who’s in the market for a solution to help optimize your department, this article will help you understand the key differences. This article delves into three key differences between CMMS and EAM software and identifies scenarios where each system is most beneficial.

Before we get into the three key differences, let's define what CMMS and EAM software are.

What is CMMS?

Computerized Maintenance Management System (CMMS) is software designed to streamline maintenance management processes. It facilitates the scheduling of preventive maintenance, tracks work orders and maintenance history, manages inventory, and provides comprehensive reporting and analytics on asset maintenance.

Initially, CMMS software was primarily used in manufacturing and industrial sectors to streamline maintenance processes for machinery and equipment. However, as the technology has evolved, its adoption has spread to healthcare, education, hospitality, government, and even retail sectors.

Check our EASY TO USE CMMS SOFTWARE for Your Industry

What is EAM software?

Enterprise Asset Management (EAM) software is a comprehensive solution that helps organizations manage the lifecycle of their physical assets and infrastructure. EAM systems have a wide range of functions that include the procurement, maintenance, operation, and disposal of assets with the goal of optimizing asset performance and extending asset life while reducing costs.

EAM platforms were initially used by organizations in manufacturing, utilities, and transportation, but recently have expanded their reach into a broader array of industries. This includes public sector organizations, healthcare, higher education, and even large retail enterprises. The shift is largely due to advancements in EAM software capabilities, including integration with other business applications, enhanced analytics, and the ability to manage a wide variety of asset types (fleet, roads, fixed assets). This change demonstrates the growing understanding across industries of the role asset lifecycle management plays in achieving operational excellence and sustainability initiatives.

Three Key Differences between CMMS and EAM and the Best Use Case for Each

1. Scope and Functionality

CMMS software's main focus is on maintenance management. It is designed to streamline and automate maintenance tasks and work orders. It focuses on scheduling preventive maintenance, managing work orders, tracking maintenance history, and inventory control. Although most CMMS software track assets and inventory, the primary focus centers on requests, inspections, parts used, and costs related to work orders and maintenance tasks.

CMMS software is ideal for organizations looking to enhance their maintenance operations. Facilities that require a straightforward approach to managing work orders, maintenance schedules, and inventory for parts and supplies should look into a CMMS. Although these platforms can be integrated with other business applications, many organizations use them as a stand-alone or point solution. CMMS software is being used by organizations of all sizes, small, medium, and large enterprises.

EAM systems encompass a broader spectrum, going beyond maintenance activities like requests, work orders, inspections, and preventive maintenance to include the entire asset management lifecycle. This includes managing activities related to the procurement, operation, maintenance, disposal, and replacement of assets. Integrating EAM software with other business systems is the norm and expected. Integration offers a holistic view of assets across the organization.

EAM is suitable for larger enterprises with complex asset structures that span multiple locations. Organizations aiming to optimize asset performance, extend asset life, and reduce total cost of ownership (TCO) across the entire lifecycle should consider EAM.

2. Integration and Scalability

As already mentioned, CMMS systems are often stand-alone or point solutions that focus on maintenance functions. They can integrate with other systems but are mainly used for optimizing maintenance management tasks. Today, CMMS programs come in all shapes and sizes. Products vary on ease of use, deployment options (cloud vs. on-premise), industry focus, and feature capabilities. Some products focus on streamlining work orders and preventive maintenance, while others include predictive maintenance and condition monitoring.

CMMS software is a suitable solution for small to medium-sized enterprises (SMEs) or departments within larger companies focusing on improving maintenance processes. Smaller organizations with limited IT infrastructure and less financial resources find CMMS software attractive because compared to EAM, they don’t require extensive integration work, are easier to implement, and costs are lower.

EAM systems are designed to be integrated across the enterprise with other enterprise software, such as ERP systems (Enterprise Resource Planning), HRIS (Human Resource Information Systems), and accounting software. Integration allows larger enterprises to analyze asset data for strategic planning. Compared to CMMSs, EAM solutions are highly customizable and configurable and are designed to scale as the business grows.

EAMs are suitable for large organizations with a variety of physical assets (fixed and movable) across multiple sites. It's ideal for companies seeking to leverage asset management for strategic advantage, including not only operational efficiency, but also risk management, and financial planning.

3. Strategic Asset Management vs. Operational Efficiency

CMMS software aims to increase operational efficiency by improving and streamlining maintenance management processes. It helps organizations reduce downtime and maintenance costs while ensuring compliance with safety and regulatory standards.

CMMS is focused on meeting maintenance department goals. It focuses on maintenance KPIs and metrics like MTTR (mean time to repair), MTBF (mean time between failure), equipment downtime, and planned vs. reactive maintenance ratio. Organizations with a need to streamline maintenance operations, reduce asset downtime, and manage maintenance costs efficiently should consider CMMS software. This includes maintenance operations across almost any industry, manufacturing plants, healthcare facilities, educational and religious institutions, amusement parks, restaurant chains, and even casinos.

EAM provides a strategic framework for managing assets over their entire lifecycle. It focuses on long-term asset performance, risk management, and investment planning. EAM enables organizations to make informed decisions about asset utilization, capital investment, and retirement.

Organizations looking to align their asset management practices with broader business goals, such as sustainability objectives, regulatory compliance, and long-term financial planning, will find EAM to be more suited to their needs. This includes utilities, transportation companies, and government entities.

|

Scope & Functionality |

Integration & Scalability |

Strategic Asset Management vs. Operational Efficiency |

|

|

CMMS |

Maintenance activities; work orders, PMs |

Stand-alone but can be integrated with other business systems |

Operational efficiency is the priority; optimize maintenance processes |

|

EAM |

Extends beyond maintenance, to include the entire asset lifecycle; procurement to disposal |

Intended to be integrated with other business systems (ERP, HRIS, CRM) |

Strategic asset management is the priority; make strategic decisions on capital investments and risk management |

Conclusion

Choosing between CMMS and EAM depends on your organization's size, the complexity of your asset portfolio, and your long-term asset management goals. CMMS offers a focused, maintenance-driven approach that is ideal for organizations looking to enhance operational efficiency, specifically regarding maintenance activities (requests, work orders, preventive maintenance, stocking parts). CMMS software is often used as a point solution, even though it can be integrated with other business applications. In contrast, EAM provides a comprehensive, strategic framework for managing assets throughout their lifecycle. It is suitable for larger organizations seeking to optimize asset performance while aligning asset management with broader business objectives. EAM software should never be used as a stand-alone solution and is intended to be integrated with other business applications across the enterprise.

Both CMMS and EAM software offer valuable tools for managing assets, but their effectiveness ultimately depends on how well they align with your organizational strategy and operational requirements. It is worth noting that there has been a convergence between these solutions, and many software providers offer both CMMS and EAM. It’s not uncommon for organizations to start off with CMMS software to manage work orders for its facilities and assets, and then upgrade to an EAM as its business grows and strategic asset management becomes a bigger priority. The shift from on-premise to cloud deployment has made upgrading from CMMS to EAM much easier and less costly than in the past. By considering your needs and the key differences outlined in this article, you should be better equipped to evaluate what solution is best for your organization.

TABLE OF CONTENTS

Keep Reading

Ever find yourself checking into a luxury hotel and expecting a relaxing stay, only to find a ...

11 Apr 2025

Organizations are witnessing swift changes in the business environment and confronting a ...

8 Apr 2025

Last month, news outlets and the entire internet was abuzz with the return of NASA astronauts ...

3 Apr 2025

What comes first - CMMS or predictive maintenance? If your answer is either, it is correct. ...

28 Mar 2025

Artificial intelligence (AI) talk has become commonplace. Today, engaging in business-focused ...

27 Mar 2025

Imagine a world where machines predict, diagnose, and fix their issues before they fail. This ...

25 Mar 2025

A facility maintenance plan is at the core of a facility’s operations. This organized ...

21 Mar 2025

Think of managing your maintenance operations like managing a championship sports team. Just ...

21 Mar 2025

The maintenance sector is battling a severe talent shortage that threatens to undermine ...

7 Mar 2025

Manufacturing maintenance is the backbone of industrial efficiency, ensuring machines run ...

5 Mar 2025

No one likes playing a guessing game when equipment breaks down. Yet, maintenance teams often ...

4 Mar 2025

The size of the preventive maintenance software market is discussed in millions of dollars, ...

4 Mar 2025

The organizational structure and corporate hierarchy vary from company to company. Large ...

28 Feb 2025

Maintenance procedures are essential for ensuring the longevity and reliability of machinery ...

21 Feb 2025

Sustainability is no longer just a buzzword; it's a critical component of corporate social ...

20 Feb 2025

A Computerized Maintenance Management System (CMMS) relies on accurate, well-organized data ...

18 Feb 2025

In an era where technology drives operational efficiency, Computerized Maintenance Management ...

14 Feb 2025

A Computerized Maintenance Management System (CMMS) is a key component of modern maintenance ...

13 Feb 2025

Introduction Maintenance management is the foundation of maintenance operations in industries ...

11 Feb 2025

Introduction A Computerized Maintenance Management System (CMMS) is software designed to help ...

7 Feb 2025