8 Key Advantages of CMMS Software that Maximize Operational Efficiencies for Businesses

Computerized Maintenance Management Software (CMMS) was first launched in 1965, and by the mid 1980s, it became a popular tool in Asset Management. Over the years, CMMS has become an essential operational application that can streamline the maintenance management process of organizations across industry sectors. It offers companies, large and small, a way to record asset data, scrutinize it, conduct preventive maintenance tasks, generate reports, create work orders, and improve worker productivity.

The best feature of the CMMS is that it can be used on any device, desktop, laptop, tablet, or smartphone. It can be deployed in-house, or in collaboration with professional external agencies. It is a powerful system that can simplify maintenance processes and is used by teams in various industries such as retail, ecommerce, manufacturing, healthcare, oil and gas, education, power, and communication.

According to a popular study and statistical analysis, CMMS offers the following capabilities:

- Enhances individual and firm productivity and improves daily maintenance activities

- Focuses on machine efficiency, product quality, and labor productivity

- Helps maintain an environmentally friendly operation by reducing the need for paper-based records of checklists and in turn, shortens the time relating to work order processing and equipment repairs.

What is a CMMS?

CMMS is a maintenance management software that enhances and automates maintenance activities. Maintenance management activities may involve machinery, automobiles, equipment, or any other service-related asset as simple as changing a light bulb. The primary objective of using an effective CMMS software is to enhance productivity, improve safety, reduce errors, lower costs, and use all facility resources efficiently.

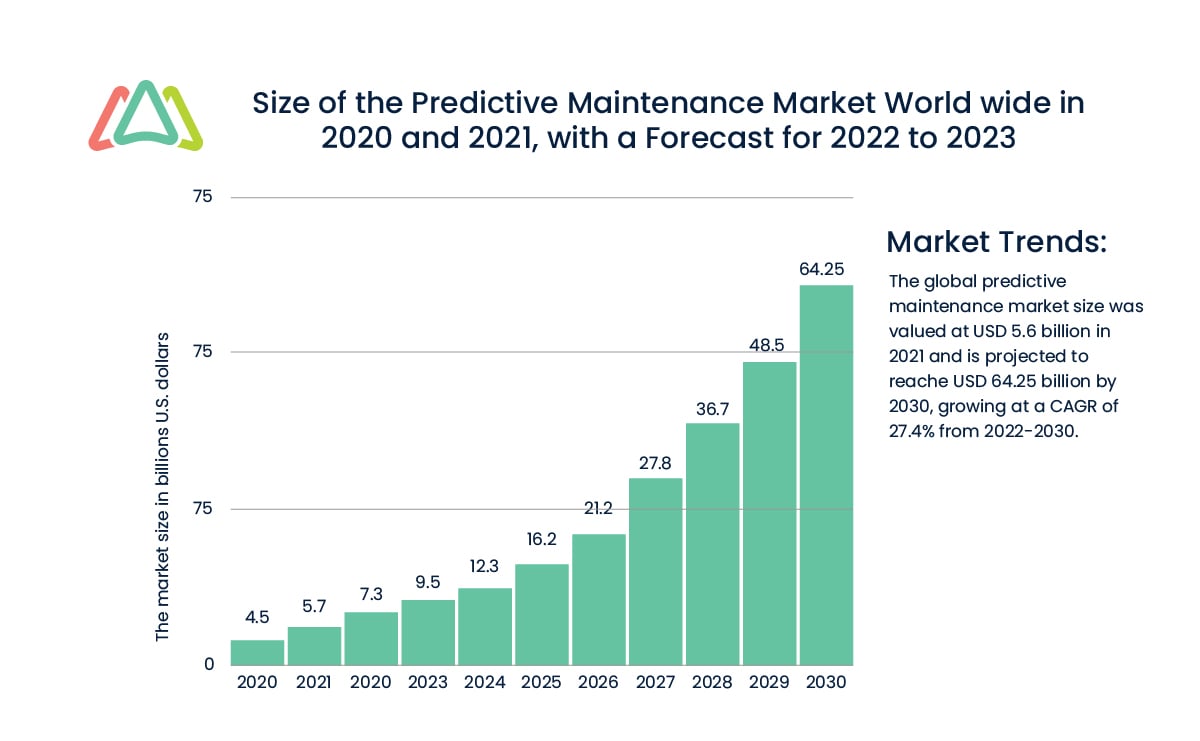

The CMMS Market Revenue is expected to reach USD 4215.1 million by 2033, by growing steadily at a CAGR of 9.1% from 2023 to 2033. The demand for CMMS is mainly from small and mid-sized businesses, which see benefits to balancing resources, preventing internal and external failures, and lowering costs.

According to a recent study, there is strong evidence that CMMS works effectively in low-resource settings, highly impacts the functionality of facilities, and indirectly contributes to greater availability and equity of services, in general.

Source: Next Move Strategy Consulting

A mobile CMMS can expedite enterprise processes like planning and scheduling asset maintenance tasks, conducting a root cause analysis, and accessing and updating work order information. Overall, an effective CMMS can streamline this entire maintenance procedure saving time, cost, and effort.

Let's dive into the reasons why a CMMS is important in driving Operational Excellence

1. Improves asset life expectancy

According to a recent report, digitalization is important for the success of any industry. CMMS incorporates preventive and protective maintenance of assets, keeps a check and maintains an inventory and asset management record, and helps in reporting, analyzing, and auditing. Over time, these processes lead to better management, wherein stakeholders can be informed in real time of the functionality of any given asset, and whether there is a need for any preventive or proactivity measure that needs to be taken to bring it back to full efficiency. By utilizing workflow management, automation, and a streamlined process, CMMS increases the lifecycle of assets and prevents lengthy disruptions in production.

2. Reduces cost

According to a recent case study, it demonstrated that when using CMMS solutions within organizations, maintenance budgets were reduced by 5-15% in the following ways

- Reduced unplanned shutdowns and equipment downtime

- Prolonged asset life

- Shortened technician overtime and average time to repair

3. Enhances customer satisfaction

CMMS solutions streamline processes, by eliminating miscommunication, errors, and omissions. These benefits extend to company customers who receive items quicker. They also improve relationships with all stakeholders. When equipment and organizational assets are well-maintained regularly, businesses can improve the consumer experience, generate positive word of mouth, and promote repeat business.

4. Ensures 100% compliance

CMMS solutions help organizations comply with facility and asset safety standards. An automated asset maintenance system reduces opportunities for lagged maintenance measures that could result in injuries. A CMMS system monitors safety measures and requirements, and in turn, prevents injuries, and helps businesses avoid OSHA violations and fines. Maintaining proper records, creating reports, storing photos, and documenting compliance activities facilitates inspections and audits, making 100% compliance achievable.

5. Helps in eliminating equipment defects

CMMS helps reduce downtime, accurately forecast defects, work on maintenance backlogs, and make preventive maintenance easier to schedule and complete. Preventive maintenance CMMS focuses on the following:

- Testing the condition of assets

- Servicing them

- Calibrating and inspecting them from time-to-time

- Ordering parts and installing parts

6. Fosters environmental-friendliness

One of the key factors of CMMS is to keep assets working at peak efficiency, reducing the need for paperwork and preventing unnecessary costs, repairs or replacements of equipment. An effective CMMS system reduces material waste, enhances employee safety, decreases energy consumption, minimizes environmental exceedance such as leaks, spills, and other emissions, and optimizes delivery miles. With mobile accessibility, creating digital work orders and working on electronic documentation has become easier and timely. CMMS leads to reduced resource use, optimized maintenance, and minimized environmental hazards.

7. Improves workflow and reporting

Sixty-six percent of organizational teams utilize CMMS solutions to improve workflow, reporting, and other maintenance activities.

CMMS promotes effective communication within organization maintenance teams. Maintenance managers are able to manage periodic tasks, oversee work orders, follow timelines, assign duties, and create maintenance processes, according to the system’s analysis reports. This results in an improvement in the overall workflow of technicians and increases the lifecycle of company assets.

8. Enhances employee productivity and accountability

CMMS helps to increase employee engagement, productivity, and accountability. Since all work orders and necessary reporting are automated by the system, the work order process, based on clearly understood criteria, can be easily followed by technicians.

An automated system is able to help technicians understand equipment failure and apply predictive and protective measures in routine maintenance schedules. With the help of a CMMS, technicians are able to work more efficiently when there isn’t a need for lengthy explanations, pen and paper reporting, or unnecessary errors due to a breakdown in communication.

The Modern Imperative: CMMS as the Essential Tool for Organizations

Organizations are increasingly turning to CMMS systems to enhance efficiency and productivity. Some key maintenance activities include: maintaining assets of an enterprise, preserving the functionality of equipment, conducting facility maintenance and cleaning, sustaining the environment, and complying with safety standards.

Regular use of a CMMS solution enables enterprises to focus on products and services, as well as meet long-term return-generating goals. The bottom line is that an effective CMMS solution can lead to efficient asset utilization, cost savings, and decision-making capabilities. CMMS can meet the demand of modern organizations to remain competitive in their industry’s marketplace.

When considering a CMMS, it is advisable to seek guidance from an expert to identify the optimal CMMS solution for your organization. The CMMS market has witnessed significant growth, offering a multitude of options. The challenge lies in selecting the solution that aligns with your company's specific needs and objectives. Once the ideal system is identified, your organization can experience remarkable growth, enhanced maintenance management processes, and improved employee satisfaction and efficiency.

TABLE OF CONTENTS

Keep Reading

Ever find yourself checking into a luxury hotel and expecting a relaxing stay, only to find a ...

11 Apr 2025

Organizations are witnessing swift changes in the business environment and confronting a ...

8 Apr 2025

Last month, news outlets and the entire internet was abuzz with the return of NASA astronauts ...

3 Apr 2025

What comes first - CMMS or predictive maintenance? If your answer is either, it is correct. ...

28 Mar 2025

Artificial intelligence (AI) talk has become commonplace. Today, engaging in business-focused ...

27 Mar 2025

Imagine a world where machines predict, diagnose, and fix their issues before they fail. This ...

25 Mar 2025

A facility maintenance plan is at the core of a facility’s operations. This organized ...

21 Mar 2025

Think of managing your maintenance operations like managing a championship sports team. Just ...

21 Mar 2025

The maintenance sector is battling a severe talent shortage that threatens to undermine ...

7 Mar 2025

Manufacturing maintenance is the backbone of industrial efficiency, ensuring machines run ...

5 Mar 2025

No one likes playing a guessing game when equipment breaks down. Yet, maintenance teams often ...

4 Mar 2025

The size of the preventive maintenance software market is discussed in millions of dollars, ...

4 Mar 2025

The organizational structure and corporate hierarchy vary from company to company. Large ...

28 Feb 2025

Maintenance procedures are essential for ensuring the longevity and reliability of machinery ...

21 Feb 2025

Sustainability is no longer just a buzzword; it's a critical component of corporate social ...

20 Feb 2025

A Computerized Maintenance Management System (CMMS) relies on accurate, well-organized data ...

18 Feb 2025

In an era where technology drives operational efficiency, Computerized Maintenance Management ...

14 Feb 2025

A Computerized Maintenance Management System (CMMS) is a key component of modern maintenance ...

13 Feb 2025

Introduction Maintenance management is the foundation of maintenance operations in industries ...

11 Feb 2025

Introduction A Computerized Maintenance Management System (CMMS) is software designed to help ...

7 Feb 2025