How to Determine if Preventive Maintenance Software is Right for Your Business

Introduction

Until recently, preventive maintenance software was a foreign idea for most businesses. For most businesses, the preferred approach for maintaining assets was reactive maintenance; dealing with equipment breakdowns and failures as they cropped up. When preventive maintenance software was first introduced, maintenance professionals were reluctant to buy into this new approach because they believed that conducting routine checks or servicing equipment when it wasn’t needed, was too costly and time consuming. However, after being shown the aggregate costs associated with unscheduled work stoppages to conduct repairs, reduced work flow due to poorly performing equipment and the cost of replacing it, maintenance managers realized that adopting a preventive maintenance strategy with a CMMS had huge cost savings.

As preventive maintenance software began making inroads into larger manufacturing facilities, company owners from other industry, service, commercial and retail sectors also took notice. Among other things, they were drawn to the Computerized Maintenance Management System’s (CMMS) sophisticated and robust capability of managing all aspects of a company’s preventive maintenance program. Over the years, CMMS preventive maintenance software continued to evolve by keeping pace with industry and technological developments. The integration of sensors to assess equipment functioning is one example how CMMS have taken advantage of emerging technological developments.

What is Preventive Maintenance Software?

In simple terms, preventive maintenance software is a tool used by organizations to schedule, plan, and track maintenance activities on equipment, machinery, or assets. The term, “preventive” reflects a proactive approach to be implemented to overall maintenance. The goals of preventive maintenance are: preventing breakdowns, reducing downtime, and extending the lifespan of assets.

Although the goals of preventive maintenance software appear relatively straightforward, CMMS capabilities are anything but that. Today’s CMMSs have moved well beyond a “one size fits all” software. In fact, the CMMS market has many vendors offering systems capable of meeting a wide range of needs and performance functions.

The major features of preventive maintenance software include:

- Maintenance Scheduling allows users to create customized maintenance schedules based on time intervals, meter readings, usage thresholds, or predefined triggers.

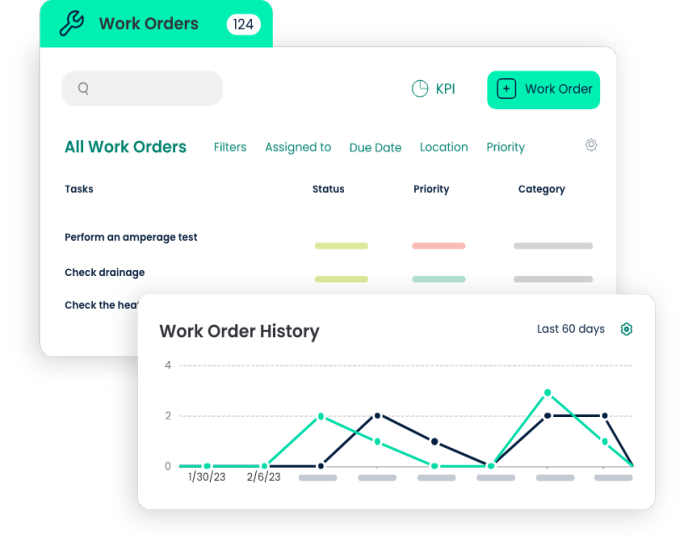

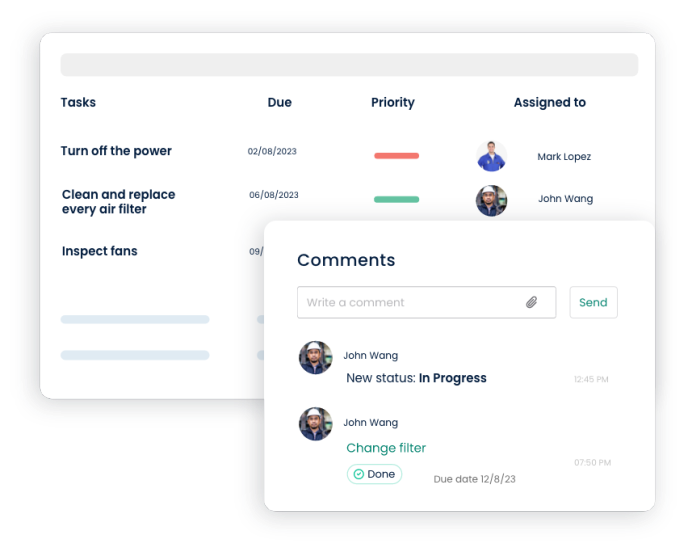

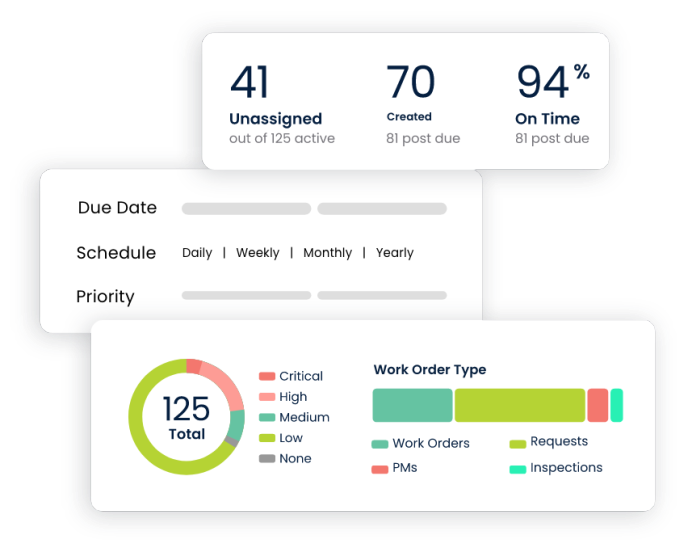

- Work Order Management feature makes it possible to create, assign, and track work orders for maintenance tasks. Maintenance managers are able to organize and prioritize maintenance activities more efficiently by taking advantage of options such as task description, assigned personnel, priority, estimated time, and completion status.

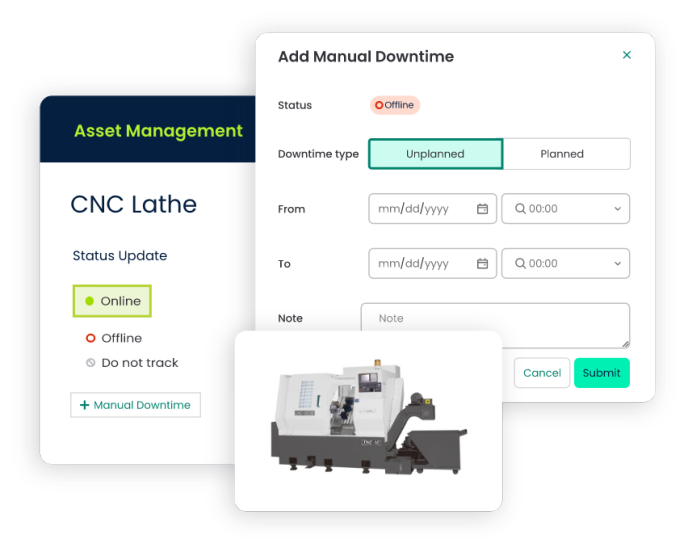

- Asset Management is a function made possible via the software’s centralized database of assets, equipment, or machinery, including information like make, model, serial number, warranty details, maintenance history, and associated documents. This function keeps track of asset performance, maintenance requirements, and replacement schedules.

- Task Checklists and Procedures can be accessed through the software’s checklist templates for common maintenance tasks. The preventive maintenance checklists ensure that technicians follow standardized procedures and cover all necessary steps during maintenance activities, improving consistency and quality.

- Notifications and Reminders can be set through the software. Notifications and reminders can be sent automatically to maintenance teams and stakeholders, alerting them about upcoming or overdue maintenance tasks.

- Data Reports can be generated by the software providing valuable insights on maintenance activities, asset performance, maintenance costs, and other key metrics.

- Integration with Other Systems like enterprise resource planning (ERP), asset management systems, and IoT devices makes preventive management software even more powerful. When systems are able to “talk to each other” through seamless data exchange, the results are better coordination between departments, and a holistic view of the organization's maintenance operations.

Businesses that Use Preventive Maintenance Software

As a starting point in determining if preventive maintenance software is right for your particular business, it’s important to note that this software can be beneficial in any industry that relies on equipment, machinery, or critical assets. It helps businesses proactively manage maintenance tasks, reduce downtime, extend asset lifespan, and enhance operational efficiency. With that being said, let’s start by looking at a list of the various businesses in industries that have benefited from preventive maintenance software. Most businesses do not need a complex software. A simple preventive maintenance software such as Click Maint would do just fine.

Manufacturing and Industrial Facilities

These facilities depend on the proper functioning of many pieces of equipment of varying types. Preventive maintenance software helps schedule regular maintenance tasks, tracks equipment history, and alerts maintenance teams to timely inspections and repairs, minimizing downtime and increasing productivity.

Fleet Management Companies

Companies that operate a fleet of vehicles, such as logistics, transportation, and delivery services, can benefit from preventive maintenance software’s ability to track vehicle maintenance schedules, monitor mileage, and provide alerts for oil changes, tire rotations, and other routine maintenance tasks. These capabilities can reduce breakdowns, extend the lifespan of vehicles, and optimize fleet performance.

Healthcare Facilities

Healthcare settings like hospitals, clinics, and laboratories are increasingly turning to preventive maintenance software as its first choice in its maintenance operations. It helps manage maintenance tasks for medical equipment, such as MRI machines, X-ray equipment, and diagnostic instruments. Regular maintenance ensures the accuracy of medical test results, reduces equipment downtime, and improves patient care.

Hospitality Industry

Hotels, resorts, restaurants and other hospitality establishments have found using preventive maintenance software as a way to keep their facilities in top condition. The software helps schedule maintenance for rooms, common areas, and amenities like HVAC systems, plumbing, electrical systems, and elevators (also called HVAC preventive maintenance software). By preventing unexpected failures, it enhances guest satisfaction and reduces operational disruptions.

Data Centers

Scheduled preventive maintenance is critical for data centers, which house servers, network equipment, and other IT infrastructure. This equipment is extremely sophisticated, expensive, and requires timely and specialized routine maintenance. The software can assist in monitoring temperature and humidity levels, managing UPS (Uninterruptible Power Supply) systems, and scheduling preventive maintenance for cooling systems and backup generators. This ensures continuous uptime and minimizes the risk of costly equipment failures.

Property Management Companies

Companies that manage residential or commercial properties can benefit from preventive maintenance software to streamline its maintenance operations by scheduling inspections, tracking repair requests, and managing maintenance tasks for HVAC systems, plumbing, electrical systems, and other building components.

Energy and Utilities

Preventive maintenance software is used in the energy and utilities sector, where it aids in managing power generation facilities, distribution networks, and equipment maintenance. Among its many benefits, the software helps optimize maintenance schedules, detect early signs of equipment failure, and improve the overall reliability and safety of power generation and distribution infrastructure.

Ways to Determine if Preventive Maintenance Software is the Right Way to Go

Determining whether preventive maintenance software is right for your business involves evaluating your specific needs, considering the benefits of implementing such software, and assessing the potential impact on your operations. Here are some steps to help you make an informed decision:

1. Identify your maintenance requirements

Begin by assessing your current maintenance practices and determine if you face specific challenges such as frequent breakdowns, unplanned downtime, inefficient scheduling, or difficulty in tracking maintenance activities. When conducting your assessment, take into account the scale of your maintenance operations, the number of assets or equipment involved, and the complexity of your maintenance tasks.

2. Consult with stakeholders

Involving key stakeholders in the decision-making process is a step that should never be overlooked or under-estimated. Be sure to seek input from maintenance managers, technicians, IT personnel, and other relevant departments. It’s crucial to consider their perspectives, concerns, and requirements to ensure the software aligns with their needs and workflows.

3. Research preventive maintenance software options

Explore different preventive maintenance software solutions available in the marketplace. Look for features that align with your requirements, such as asset management, work order management, scheduling and planning, inventory management, reporting and analytics, and integration capabilities. Be sure to read reviews, compare functionalities, and consider the reputation and reliability of the software providers. Take your time with this step since it will lay the foundation in your final decision making.

4. Evaluate the benefits

Consider the potential benefits of preventive maintenance software implementation. These may include improved equipment reliability, reduced downtime and repair costs, enhanced asset lifespan, streamlined maintenance processes, increased operational efficiency, better resource utilization, improved safety, and compliance with regulatory requirements. Assess how these benefits align with your business goals and objectives.

At the same time, also consider any potential disadvantages to implementing a preventive maintenance software. Think about the software’s ongoing cost, the time required to complete the CMMS implementation, the resources needed to do so, as well as your company’s receptiveness to adopting new maintenance procedures.

5. Assess scalability and flexibility

Determine if the software is able to scale as your business grows and accommodates future needs. The software must have growth capabilities to be of value to your business. When making this determination, take into account factors such as the number of users and assets the software can handle, multi-site capabilities, and whether it can adapt to changes in your maintenance processes or industry-specific requirements.

6. Consider implementation and integration

Carefully assess the ease of implementation and integration of the preventive maintenance software with your existing systems. Check CMMS integration with other tools or platforms you use, such as enterprise resource planning (ERP) systems or Internet of Things (IoT) devices. Most important, assess the level of technical support provided by the software vendor during implementation and ongoing usage.

7. Calculate the return on investment (ROI)

The bottom line is the most defining factor for all businesses. When determining if preventive maintenance software will be advantageous for your business, the bottom line has to be considered. To do so, estimate the potential cost savings and productivity gains that can result from implementing preventive maintenance software. Think about factors such as reduced equipment downtime, minimized reactive maintenance costs, optimized inventory management, improved labor efficiency, and better compliance. Compare these potential benefits with the cost of acquiring and maintaining the software. The results of these calculations will let you know if going forward with preventive maintenance software is the right choice for your business at this time.

The formula to calculate CMMS ROI is as follows:

Return on Investment (ROI)

= (Net Savings - Total Costs) / Total Costs * 100

Where:

- Net Savings: This is the total amount of money saved or gained as a result of implementing the CMMS. It includes both tangible and intangible benefits. To calculate net savings, quantify the various benefits the CMMS brings, such as reduced downtime, improved labor efficiency, extended equipment lifespan, better inventory management, and other cost savings. Add up all the quantified savings to get the net savings value.

- Total Costs: This includes all the expenses associated with acquiring, implementing, and operating the CMMS. It covers costs such as software licensing fees, implementation costs, training expenses, hardware and infrastructure costs, and ongoing maintenance fees. Sum up all these costs to get the total costs value.

8. Seek user feedback and references

Reach out to other businesses or industry peers who have implemented preventive maintenance software; especially the one you are contemplating. Ask for their experiences, insights, and recommendations. You may also consider joining industry forums or online communities to get a broader perspective and learn from others' experiences.

9. Make an informed decision

After gathering all the necessary information, the final step is to carefully weigh the benefits, costs, and potential risks associated with implementing preventive maintenance software. Once again, evaluate how well it aligns with your business objectives, current infrastructure, and long-term plans. Then, consider the insights from your evaluation process, user feedback, and ROI analysis to make a well-informed decision.

As you progress in deciding on the best software, we encourage you to read "The Unfiltered Truth about Free Preventive Maintenance Software."

Conclusion

Overall, preventive maintenance software streamlines maintenance processes, minimizes equipment downtime, reduces unexpected breakdowns, and improves the overall efficiency of maintenance operations. By implementing a proactive approach to maintenance, organizations can save costs, enhance asset reliability, and optimize their maintenance resources. Remember though, the challenge is to find a solution that best suits your business's unique set of requirements and goals. By following the steps outlined in this article, you will be guided in making a decision that’s right for your business.

TABLE OF CONTENTS

Keep Reading

Ever find yourself checking into a luxury hotel and expecting a relaxing stay, only to find a ...

11 Apr 2025

Organizations are witnessing swift changes in the business environment and confronting a ...

8 Apr 2025

Last month, news outlets and the entire internet was abuzz with the return of NASA astronauts ...

3 Apr 2025

What comes first - CMMS or predictive maintenance? If your answer is either, it is correct. ...

28 Mar 2025

Artificial intelligence (AI) talk has become commonplace. Today, engaging in business-focused ...

27 Mar 2025

Imagine a world where machines predict, diagnose, and fix their issues before they fail. This ...

25 Mar 2025

A facility maintenance plan is at the core of a facility’s operations. This organized ...

21 Mar 2025

Think of managing your maintenance operations like managing a championship sports team. Just ...

21 Mar 2025

The maintenance sector is battling a severe talent shortage that threatens to undermine ...

7 Mar 2025

Manufacturing maintenance is the backbone of industrial efficiency, ensuring machines run ...

5 Mar 2025

No one likes playing a guessing game when equipment breaks down. Yet, maintenance teams often ...

4 Mar 2025

The size of the preventive maintenance software market is discussed in millions of dollars, ...

4 Mar 2025

The organizational structure and corporate hierarchy vary from company to company. Large ...

28 Feb 2025

Maintenance procedures are essential for ensuring the longevity and reliability of machinery ...

21 Feb 2025

Sustainability is no longer just a buzzword; it's a critical component of corporate social ...

20 Feb 2025

A Computerized Maintenance Management System (CMMS) relies on accurate, well-organized data ...

18 Feb 2025

In an era where technology drives operational efficiency, Computerized Maintenance Management ...

14 Feb 2025

A Computerized Maintenance Management System (CMMS) is a key component of modern maintenance ...

13 Feb 2025

Introduction Maintenance management is the foundation of maintenance operations in industries ...

11 Feb 2025

Introduction A Computerized Maintenance Management System (CMMS) is software designed to help ...

7 Feb 2025