The Role of Technology in Driving Supply Chain Collaboration in the Manufacturing Industry

In today's fast-paced manufacturing industry, your ability to collaborate effectively across the supply chain can make or break your competitive edge. As we navigate the complexities of global markets and ever-changing customer demands, technology plays a pivotal role, emerging as a powerful enabler of seamless coordination and information sharing. Furthermore, as we delve into the complexities of modern manufacturing, we find that leveraging cutting-edge tools and platforms is essential for staying competitive. From enhancing real-time communication to optimizing inventory management, technology is revolutionizing how you interact with suppliers, partners, and customers.

This article explores the critical role of technology in driving supply chain collaboration within the manufacturing industry, examining key trends, real-world applications, and the tangible benefits you can achieve by embracing these digital tools to streamline operations and boost productivity. By embracing these technological advancements, leaders can position their organizations at the forefront of industry innovation and drive sustainable growth in an increasingly interconnected global marketplace.

The Importance of Supply Chain Collaboration in Manufacturing

In today's complex manufacturing landscape, supply chain collaboration has become a critical factor for success. By fostering strategic partnerships and leveraging advanced technologies, manufacturers can achieve greater efficiency, reduce costs, and make smart maintenance decisions that drive efficiency and reduce costs. Effective collaboration enables real-time information sharing, leading to improved forecasting and inventory management. This interconnected approach allows companies to respond quickly to market changes and consumer demands. Ultimately, a well-coordinated supply chain enhances product quality, speeds time-to-market, and creates a cost-efficient ecosystem that benefits all stakeholders in the manufacturing process.

Boosting Operational Efficiency

Supply chain collaboration enables manufacturers to streamline processes and optimize resource allocation. Through real-time data sharing and joint planning, companies can minimize inventory discrepancies and reduce lead times.

This enhanced visibility allows for more cost-efficient operations and improved responsiveness to market demands.

Driving Innovation and Quality

Collaborative efforts between manufacturers and suppliers often lead to innovative solutions and improved product quality. By working closely with partners, companies can tap into diverse expertise and resources, fostering a culture of continuous improvement. This synergy not only enhances product development but also contributes to more effective quality control measures.

Mitigating Risks and Building Resilience

In an era of increasing supply chain disruptions, collaboration plays a vital role in risk management. By sharing information and aligning strategies, manufacturers can better anticipate and respond to potential challenges. Implementing a CMMS (Computerized Maintenance Management System) further supports this effort by enabling proactive maintenance and reducing downtime.

How Technology Enables Seamless Collaboration

Real-Time Information Sharing

In today's fast-paced manufacturing landscape, real-time information sharing is crucial for seamless collaboration. Cloud computing provides a centralized platform for storing and sharing data, enabling instant access across teams, partners, and customers. This transparency allows for better forecasting and more informed, cost-efficient decision-making throughout the supply chain.

Advanced Analytics and Al

The integration of artificial intelligence and advanced analytics is revolutionizing supply chain collaboration. These technologies can analyze complex data sets to generate insights and automate repetitive tasks, freeing up resources for strategic planning. By leveraging Al-powered platforms, manufacturers can make smart maintenance decisions and optimize their operations for maximum efficiency.

IoT and Real-Time Monitoring

The Internet of Things (IoT) connects smart sensors and devices to monitor and optimize manufacturing processes in real time. This constant stream of data enables better visibility into production, helping businesses identify and mitigate potential issues quickly. A modern CMMS system can elevate this capability, ensuring equipment uptime and streamlining maintenance activities.

Improved Forecasting and Planning

Artificial Intelligence (AI) and predictive analytics are transforming demand forecasting and inventory management. These technologies enable manufacturers to anticipate market changes and optimize stock levels, leading to more cost-efficient operations. According to a recent study, digital transformation enhances key supply chain capabilities, including information exchange and responsiveness.

Streamlined Communication and Collaboration

Cloud-based platforms are breaking down silos between supply chain partners, facilitating seamless information sharing and collaboration. This improved connectivity allows for more agile decision-making and faster problem-solving. As noted by Harvard Business Review, modern supply chain technology platforms provide the necessary flexibility to adapt to unexpected disruptions, ultimately building resilience in an increasingly volatile market.

Key Benefits of Supply Chain Collaboration Technologies

Enhanced Efficiency and Cost Reduction

Supply chain collaboration technologies enable manufacturers to make smart maintenance decisions and implement cost-efficient strategies. By facilitating real-time information sharing, these tools help lower inventory levels and increase inventory turns, leading to reduced warehousing costs. Moreover, they streamline communication and optimize procedures, resulting in lower long-term operational expenses.

Improved Product Quality and Time-to-Market

Collaborative platforms provide a 360-degree view of the manufacturing process, allowing companies to address quality issues at the source. This comprehensive visibility enhances product quality and safety. Additionally, by working directly with suppliers through these technologies, manufacturers can significantly reduce product development time and costs, enabling faster responses to market trends.

Strengthened Partnerships and Innovation

CMMS software and other collaboration tools foster long-term relationships between manufacturers and their partners. As these relationships deepen, suppliers proactively share industry advancements, helping manufacturers stay competitive. This collaborative environment also drives business growth through innovation and accelerated new product development, ensuring continuous improvement in the manufacturing process.

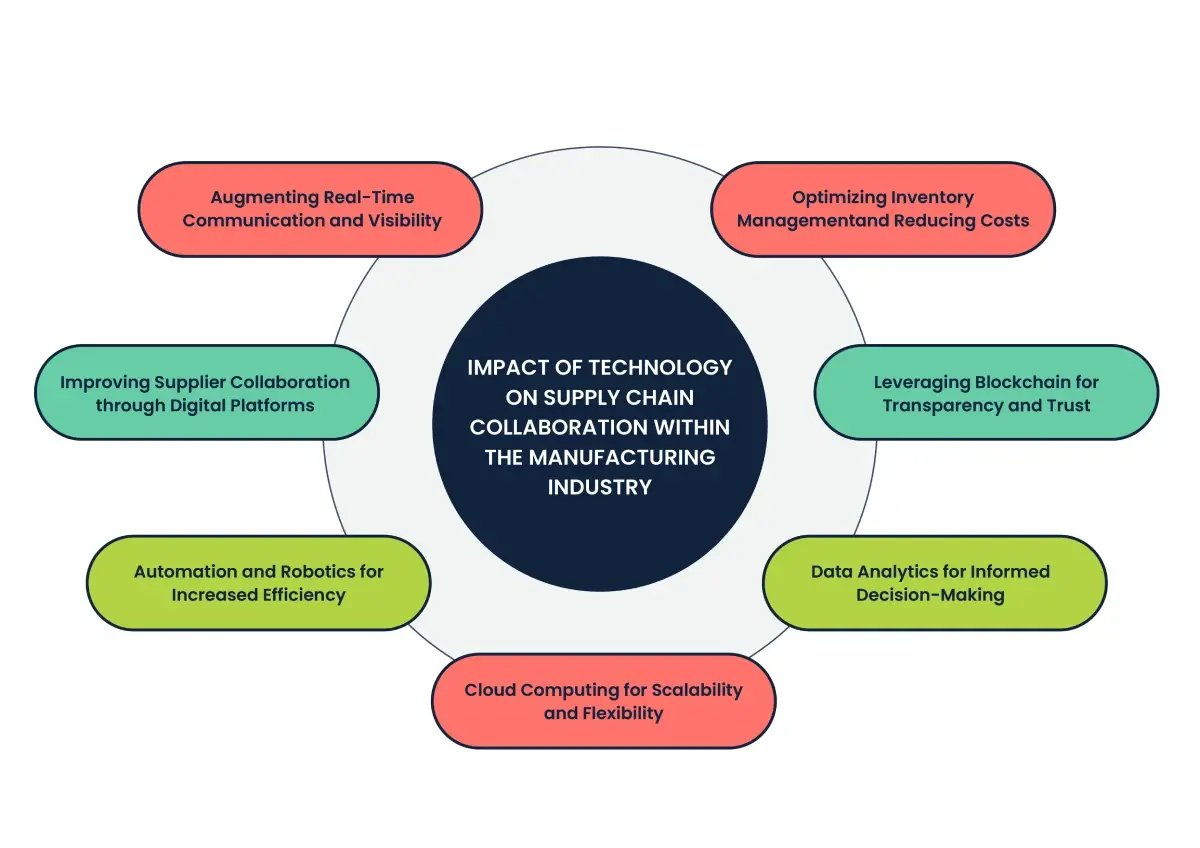

The Transformative Impact of Technology on Supply Chain Collaboration within the Manufacturing Industry

Technology has revolutionized supply chain collaboration in the manufacturing industry, enabling cost-efficient operations and smart maintenance decisions. Through advanced CMMS systems, companies can streamline processes, enhance real-time communication, and optimize inventory management. Digital platforms facilitate seamless supplier collaboration, while blockchain technology ensures transparency and trust. Automation and robotics boost efficiency, data analytics drive informed decision-making, and cloud computing provides scalability. These innovations collectively transform how manufacturers interact, share information, and collaborate across their supply chains, fostering a more agile and responsive industry ecosystem.

Augmenting Real-Time Communication and Visibility

According to a study by McKinsey, companies that adopt IoT technologies see up to a 25% reduction in maintenance costs and a cut in unplanned outages by up to 50%

- In the manufacturing industry, real-time communication is crucial for supply chain collaboration. Real-time communication and visibility are vital for effective supply chain collaboration.

- Technologies such as IoT (Internet of Things) devices, RFID (Radio Frequency Identification), and GPS tracking provide instant updates on inventory levels, shipment status, and production progress.

- By leveraging CMMS solutions, companies can streamline information flow, reduce delays, and improve overall efficiency. Real-time tracking and reporting capabilities empower manufacturers to make smart maintenance decisions, ensuring cost-efficient operations and minimizing disruptions in the supply chain.

For example, IoT-enabled sensors can monitor the condition and location of goods throughout the supply chain, allowing stakeholders to detect and address potential issues proactively.

By providing a holistic view of the supply chain, these technologies enable manufacturers to identify bottlenecks, improve resource allocation, and make informed decisions that foster collaboration among partners.

Optimizing Inventory Management and Reducing Costs

Research by Gartner shows that companies leveraging AI in demand forecasting experience an average of 25% reduction in excess inventory and a 20% increase in customer satisfaction.

- Efficient inventory management is crucial for minimizing costs and avoiding production delays. Technologies such as AI (Artificial Intelligence) and machine learning algorithms are transforming inventory management by predicting demand fluctuations, optimizing stock levels, and automating reordering processes.

- By leveraging advanced CMMS solutions, companies can optimize stock levels, reduce carrying costs, and minimize stockouts. These technologies enable real-time tracking of inventory, automated reordering, and predictive analytics to forecast demand accurately.

- Through enhanced supply chain collaboration, manufacturers can streamline procurement processes, negotiate better terms with suppliers, and ultimately boost their bottom line. AI-powered systems analyze historical data and market trends to forecast demand accurately, allowing manufacturers to maintain optimal inventory levels and avoid overstocking or stockouts.

By optimizing inventory management, manufacturers can reduce carrying costs, enhance cash flow, and improve collaboration with suppliers by aligning production schedules and demand forecasts.

Improving Supplier Collaboration through Digital Platforms

According to a survey by McKinsey & Company, organizations leveraging digital platforms for supplier relationship management experience up to a 35% faster supplier response time, leading to a more agile and responsive supply chain. Additionally, these organizations reported a 20% increase in supplier collaboration, fostering innovation and driving mutual growth.

- Digital platforms are revolutionizing supply chain collaboration in the manufacturing industry. These tools provide a centralized hub enabling real-time communication, document sharing, managing orders, tracking performance metrics and project management, and fostering stronger partnerships with suppliers.

- By leveraging cloud-based solutions, manufacturers can make smart maintenance decisions and streamline processes for cost-efficient operations.

- By improving transparency and communication, digital platforms help manufacturers build stronger relationships with suppliers, leading to better negotiation terms, reduced costs, and increased agility.

- A modern CMMS (Computerized Maintenance Management System) can integrate with these platforms, enhancing overall supply chain visibility and responsiveness.

Modern CMMS platforms like Click Maint CMMS offer features that allow manufacturers to streamline communication with suppliers, monitor equipment maintenance schedules, and manage spare parts inventory. This technological synergy promotes agility, reduces lead times, and ultimately drives innovation across the entire manufacturing ecosystem.

Leveraging Blockchain for Transparency and Trust

A report by PwC indicates that 24% of industrial manufacturing CEOs are planning, piloting, or implementing blockchain technology.

- Blockchain technology is revolutionizing supply chain collaboration in the manufacturing industry, offering unprecedented transparency and trust - providing a secure and transparent way to track transactions and product movements.

- By creating an immutable, decentralized ledger, blockchain enables real-time tracking of products from raw materials to end consumers. It records every transaction in the supply chain, from raw material sourcing to the final delivery of finished products. This enhanced visibility allows for more cost-efficient operations and smarter maintenance decisions.

- This level of transparency is particularly beneficial in industries with stringent regulatory requirements, such as pharmaceuticals and food manufacturing, where traceability and compliance are paramount.

- Manufacturers can easily verify the authenticity of components, reducing counterfeit risks and improving quality control.

- Implementing blockchain in your CMMS can significantly boost supply chain collaboration, fostering stronger relationships with suppliers and customers while ensuring data integrity throughout the production process.

By leveraging blockchain, manufacturers can ensure data integrity, prevent fraud, and enhance trust among stakeholders.

Automation and Robotics for Increased Efficiency

According to the International Federation of Robotics, the global market for industrial robots grew by 7% in 2023, with a significant portion of growth coming from the manufacturing sector.

- Automation and robotics are revolutionizing supply chain collaboration in the manufacturing industry by reducing manual labor, minimizing errors, and speeding up processes – driving cost-efficient operations and enabling smart maintenance decisions.

- Robotics enhance precision in inventory management and order fulfillment, while automated data collection facilitates real-time monitoring and predictive maintenance.

- This technological integration not only improves efficiency but also allows human workers to focus on higher-value tasks, fostering innovation and strategic thinking across the supply chain.

- From automated systems, such as robotic process automation (RPA) and automated guided vehicles (AGVs) in warehouses, to robotic arms on production lines, automation is driving efficiency across the supply chain.

- And by implementing advanced CMMS systems, manufacturers can streamline processes, reduce human error, and boost productivity.

- By automating repetitive tasks, manufacturers can reduce labor costs, improve accuracy, and free up human workers for higher-value activities.

Moreover, automation enhances supply chain agility by enabling manufacturers to respond quickly to changes in demand and production schedules, fostering better collaboration with suppliers and customers.

Data Analytics for Informed Decision-Making

According to a report by Accenture, a global retailer increased its profits by 28% in just three years by digitizing its supply chain process.

- Data analytics plays a crucial role in supply chain collaboration in the manufacturing industry by providing actionable insights into performance metrics, market trends, and customer preferences.

- By leveraging advanced algorithms and machine learning, companies can make smart maintenance decisions based on real-time data. This enables cost-efficient operations and predictive maintenance strategies.

- Advanced analytics tools allow manufacturers to analyze vast amounts of data from multiple sources, such as IoT devices, ERP (Enterprise Resource Planning) systems, and customer feedback.

CMMS platforms integrate seamlessly with analytics tools, providing actionable insights for inventory optimization and demand forecasting. With data-driven decision-making, manufacturers can enhance their competitive edge, reduce downtime, and improve overall supply chain performance. The future of manufacturing lies in harnessing the power of data analytics for informed, strategic choices.

By leveraging data analytics, manufacturers can identify inefficiencies, optimize processes, and make data-driven decisions that enhance collaboration across the supply chain.

Cloud Computing for Scalability and Flexibility

According to a survey by Flexera, 92% of businesses have adopted a multi-cloud strategy, with 80% of organizations prioritizing cloud adoption for supply chain management.

- Cloud computing is a game-changer for supply chain management, offering scalability, flexibility, and cost-efficiency.

- Cloud-based solutions enable manufacturers to store and access data in real time, collaborate with partners, and quickly adapt to changing market conditions.

- Cloud computing allows manufacturers to scale their operations up or down as needed, providing the flexibility to respond to demand fluctuations and supply chain disruptions.

- Additionally, cloud-based systems offer enhanced data security, ensuring that sensitive information is protected from cyber threats while enabling seamless collaboration among stakeholders.

Real-World Examples of Successful Implementations

Transforming Supply Chains with Technology

In recent years, several companies have leveraged technology to drive remarkable improvements in their supply chain operations. A leading metals producer implemented digital use cases across its value chain, resulting in a 2-5% increase in EBITDA, an 8-10% reduction in carbon emissions, and a 5-10% improvement in on-time, in-full delivery. This transformation enabled cost-efficient operations and smarter maintenance decisions.

Innovative Technologies Driving Collaboration

Emerging technologies are revolutionizing how supply chains operate, fostering unprecedented levels of collaboration and efficiency. Cloud-based platforms and the Internet of Things (IoT) enable real-time data sharing and visibility across the supply chain, helping all stakeholders make informed decisions quickly. Additionally, the integration of loT and 5G technologies has enhanced real-time tracking and monitoring capabilities. Uber Freight has deployed Volvo's autonomous transport solution, utilizing 5G-enabled sensors for near real-time product tracking.

Refining Resilience with Modern Platforms

To address supply chain vulnerabilities exposed by recent global events, companies are adopting more flexible, dynamic connections between trading partners. Modern supply chain technology platforms are enabling businesses to create responsive, adaptive supply chains that can better withstand unexpected challenges. These platforms, often incorporating CMMS software, facilitate smart maintenance decisions and cost-efficient operations, ensuring long-term resilience and competitiveness in the manufacturing industry.

How to Get Started with Supply Chain Collaboration Tech

Assess Your Current Capabilities

Before implementing new technology, it's crucial to evaluate your existing supply chain processes and infrastructure. Identify areas where collaboration could drive the most value, focusing on your strengths rather than trying to fill gaps. This approach allows for cost-efficient implementation and quicker results.

Choose the Right Technology Partners

Select supply chain collaboration software that aligns with your specific needs and goals. Look for platforms offering:

- Real-time data sharing and visibility

- Configurable workflows

- Advanced analytics for smart maintenance decisions

- Seamless communication tools

A comprehensive CMMS solution can significantly enhance collaboration by providing a unified data model and streamlining processes across your supply chain.

Foster a Collaborative Culture

Implementing technology is only part of the equation. To truly drive supply chain collaboration, focus on:

- Encouraging transparency with suppliers and internal teams

- Establishing fair benefit-sharing models

- Investing in dedicated resources and leadership support

- Implementing joint performance management systems

By fostering a culture of collaboration, you'll maximize the benefits of your new technology and drive continuous improvement throughout your supply chain.

Conclusion

Technology is revolutionizing supply chain collaboration in the manufacturing industry. By embracing digital solutions, organizations can enhance communication, optimize inventory, improve supplier relationships, increase transparency, boost efficiency, make data-driven decisions, and scale operations flexibly. As you navigate this rapidly evolving landscape, remember that the key to success lies in strategically implementing these technologies to address your specific challenges and goals. Bear in mind that successful supply chain collaboration is not just about implementing new technologies; it's about fostering a culture of innovation and continuous improvement throughout your entire ecosystem.

Embracing technological innovations is a necessity for manufacturers aiming to thrive in a highly dynamic and interconnected global market. With the right tools and strategies, the potential for supply chain collaboration to drive growth and success is limitless. As the role of technology in supply chain management continues to grow, companies that invest in digital transformation will be better positioned to thrive in the future. The future of manufacturing supply chains is digital – are you ready to lead the charge?

Ready to enhance your supply chain collaboration with the power of technology?

Discover how Click Maint CMMS can streamline your operations and boost efficiency.

TABLE OF CONTENTS

Keep Reading

The longest U.S. federal government shutdown to date lasted 43 days, beginning on October 1, ...

5 Dec 2025

Every maintenance professional faces it sooner or later — that critical time when an aging ...

18 Nov 2025

The term 'best' is often used loosely, without a clear understanding of its context or ...

14 Nov 2025

In the not too distant past, maintenance strategies have been defined by reaction—fixing ...

13 Nov 2025

Tax season is the time of year that often sends a ripple of anxiety through many of us. The ...

11 Nov 2025

Selecting a Computerized Maintenance Management System (CMMS) can, at first glance, be an ...

4 Nov 2025

In healthcare facilities, equipment uptime involves more than achieving operational ...

31 Oct 2025

Companies are subject to economic ups and downs, also known as economic volatility. Today, ...

30 Oct 2025

Maintenance challenges are a constant struggle, with unplanned downtime costing manufacturers ...

27 Oct 2025

Last winter, a maintenance technician at a U.S. paper mill ignored a predictive alert that ...

10 Oct 2025

Many organizations proudly say they “have a CMMS,” but ownership alone doesn’t equal ...

9 Oct 2025

Every maintenance team is under pressure to do more with less. Unplanned downtime is often ...

7 Oct 2025

The implementation of simple, yet powerfully effective, checklists has repeatedly ...

3 Oct 2025

In manufacturing, every second counts. When production stops, whether due to scheduled ...

2 Oct 2025

The increasing cost of maintenance, lack of accountability, and siloed systems leave many ...

30 Sep 2025

Preventive maintenance is one of those things maintenance teams know they need to do, but it ...

26 Sep 2025

Public services are essential to daily life. The provision of safe roads, functional transit, ...

25 Sep 2025

For most manufacturing facilities, a major focus of their maintenance teams revolves around ...

24 Sep 2025

Have you ever tried explaining to the CEO why the production line has been down for hours ...

18 Sep 2025

Over the past few decades, the hotel industry has undergone a dramatic transformation. ...

16 Sep 2025