CMMS for Senior Care Facilities

Seamless Maintenance, Superior Care with Click Maint

No credit card required | Start your 30 day FREE trial

TABLE OF CONTENTS

- CMMS

- Industry

- CMMS for Senior Care Facilities

Labor Efficiency Improvement

Estimated Downtime Reduction

Inventory Optimization

Trusted by thousands of maintenance & facilities professionals

How much does a CMMS cost?

Try our Price Calculator to get an Instant Estimate for Your Use Case

PROFESSIONAL PLAN

$ 42 USD

PER USER PER MONTH

$ 35 USD

PER USER PER MONTH

Senior Care Facilities Maintenance Challenges

Maintaining Safety and Accessibility for Residents

Ensuring Reliability of Medical and Assistive Equipment

Managing Wear and Tear in High-Use Areas

Balancing Comfort and Hygiene Standards

Adhering to Health and Regulatory Compliance

Budget Constraints and Resource Prioritization

How CMMS Solves these Challenges

Automated work order management

Asset downtime tracking

Maintenance history reporting

Labor and cost tracking

Inventory management and optimization

Automated preventive maintenance scheduling

Click Maint CMMS Features for Assisted Living Facilities

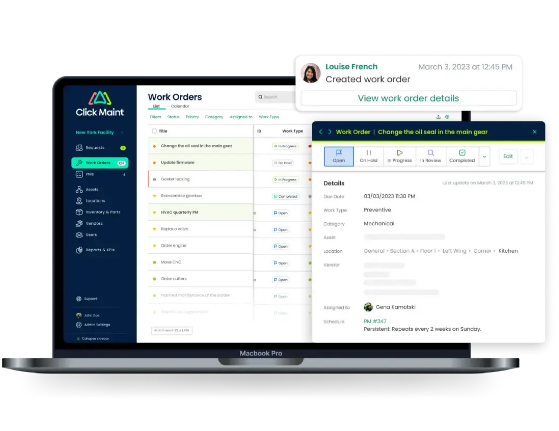

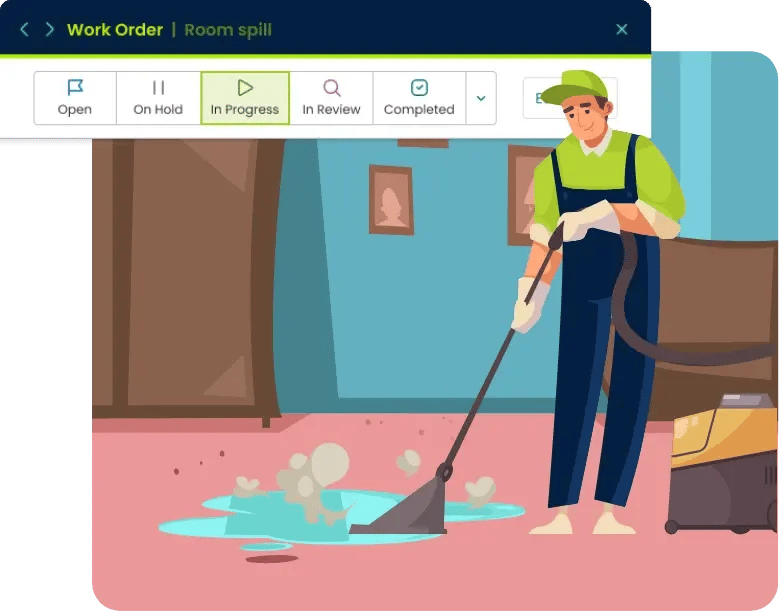

Work Order Management

Streamline maintenance tasks with an intuitive work order system. Create, assign, and track work orders easily, ensuring that all maintenance activities are documented and completed on time.

Preventive Maintenance Scheduling

Implement a proactive approach to maintenance with automated scheduling for routine checks and preventive tasks. This helps minimize equipment downtime and extend the lifespan of assets.

Asset Management

Keep a detailed inventory of all assets, including HVAC systems, medical equipment, and facility infrastructure. Track asset performance, maintenance history, and lifecycle costs to make informed decisions.

Inspections and Audits

Schedule and perform regular inspections and audits to ensure compliance with health and safety regulations. Document findings and follow up on corrective actions to maintain a safe environment for residents.

Mobile Access

Access the CMMS from any device with a mobile-friendly interface. Maintenance staff can update work orders, log issues, and access asset information on the go, improving response times and efficiency. With the mobile CMMS app, users can also capture photos of issues and easily associate them with requests, work orders, and preventive maintenance tasks. In addition, users can scan QR codes to access asset and location information instantly.

Spare Parts and Inventory Management

Manage spare parts and supplies efficiently with an integrated inventory management system. Track stock levels, set reorder points, and reduce downtime by ensuring critical parts are always available.

Reporting and Analytics

Generate comprehensive reports and analytics to gain insights into maintenance activities, asset performance, and operational efficiency. Use data-driven insights to optimize maintenance strategies and improve facility management.

Vendor Management

Keep track of vendor information, service contracts, and performance metrics. Streamline communication with external service providers and ensure timely service and support.

User-Friendly Interface

Enjoy an easy-to-use interface designed for all skill levels. Simplify training and onboarding for new staff, ensuring that everyone can use the system effectively.

Experience Click Maint CMMS now

30-Day Free Trial

No Credit Card needed.

Instant access to all features & modules with an optional live walk-through with a Click Maint expert

Book a live Demo

In this 30-minute demo, see firsthand how our easy CMMS can streamline your operations, enhance productivity, and reduce downtime.

Why is Maintenance of Senior Care Facilities Essential?

Safety and Compliance

Regulatory Requirements and Compliance Standards

Retirement homes are subject to strict regulatory requirements and compliance standards to ensure the safety and well-being of their residents. These regulations cover various aspects of facility maintenance, including fire safety, electrical systems, plumbing, and medical equipment. Regular maintenance helps facilities meet these standards, avoid penalties, and ensure that the environment remains safe and secure for residents.

Ensuring Resident Safety through Regular Maintenance

Routine maintenance checks are important for identifying and addressing potential hazards before they become serious issues. Regular inspections of HVAC systems, fire alarms, emergency lighting, and other critical systems ensure they’re all functioning correctly. By proactively managing maintenance, facility managers of retirement homes can prevent accidents, reduce the risk of injuries, and create a safer living environment for residents.

Asset Management

Managing Critical Assets Like HVAC Systems, Elevators, and Medical Equipment

Effective maintenance management involves keeping a detailed inventory of all critical assets, such as HVAC systems, elevators, and medical equipment. These assets are vital for a retirement home's daily operations and the comfort of its residents. Proper management also includes scheduling regular inspections, timely repairs, and tracking maintenance history to ensure optimal performance.

Extending the Lifespan of Assets

Regular maintenance not only ensures the immediate functionality of assets but also extends their lifespan. By performing routine checks and addressing minor issues promptly, facilities can prevent major breakdowns and expensive replacements. This approach leads to significant cost savings and ensures that essential equipment remains reliable and efficient over time.

Operational Efficiency

Reducing Downtime

Maintenance issues can significantly disrupt a retirement home's daily operations. Equipment failures or facility breakdowns can lead to downtime, affecting residents' comfort and safety. By implementing a proactive maintenance strategy, facility and maintenance managers can reduce the likelihood of unexpected breakdowns and ensure that all systems operate smoothly and consistently.

Streamlining Maintenance Processes

Utilizing a computerized maintenance management system (CMMS) can streamline maintenance processes by automating task scheduling, work order management, and inventory control. This leads to more efficient resource allocation, quicker response times to maintenance requests, faster work order completion times, and improved overall operational efficiency. A streamlined maintenance process helps staff focus on their primary duties, enhancing the quality of care provided to residents.

Resident Satisfaction

Impact of Well-Maintained Facilities on Resident Quality of Life

The condition of the facility directly influences the quality of life for residents in retirement homes. Well-maintained buildings, functional HVAC systems, reliable elevators, and properly working medical equipment contribute to a comfortable and safe living environment. Regular maintenance ensures that residents have access to all necessary amenities and services without interruptions.

Enhancing the Comfort and Satisfaction of Residents

A well-maintained facility not only improves safety but also enhances the overall comfort and satisfaction of residents. Comfortable living conditions, such as optimal room temperatures, well-lit spaces, and accessible facilities, contribute to a positive living experience. Satisfied residents are more likely to feel at home, experience better mental and physical health, and have a higher quality of life.

See how affordable Click Maint CMMS is

Submit a Work Order Using the Click Maint Mobile App

-

1

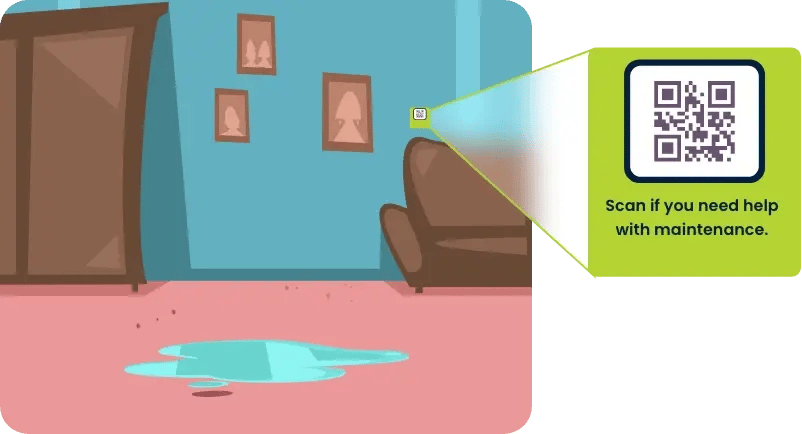

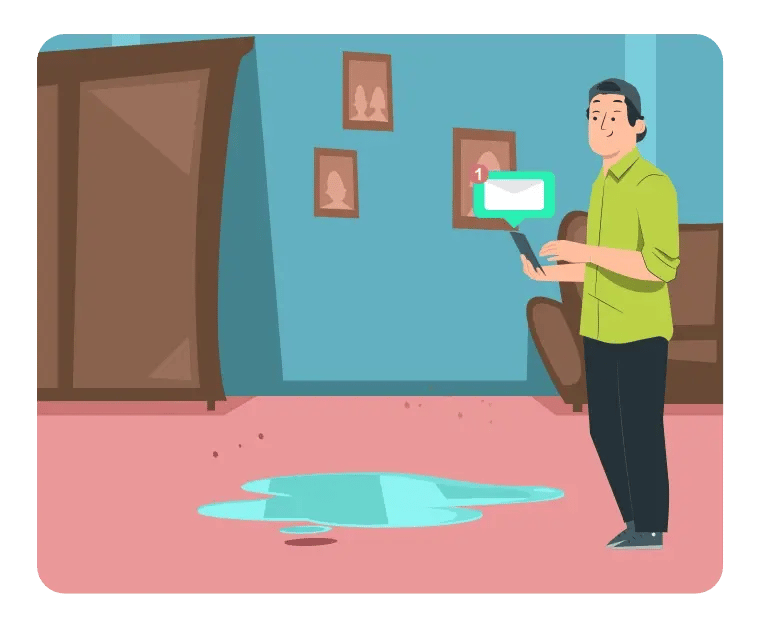

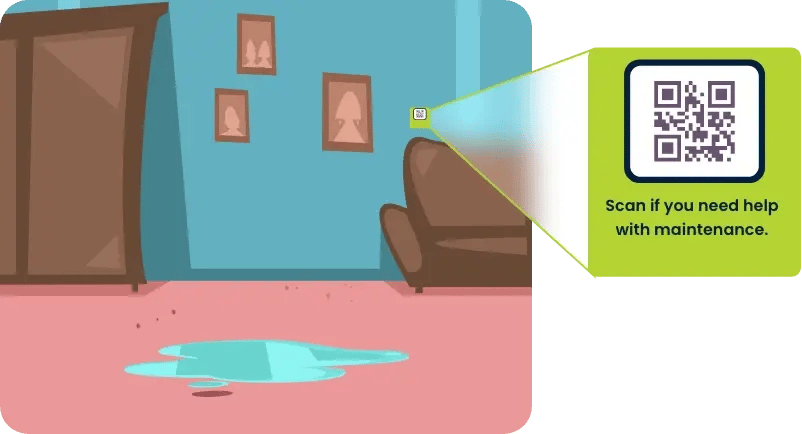

Identify the Issue

Observation: Notice a maintenance issue that needs attention, such as a spill in a room.

-

2

Scan the QR Code

Locate QR Code: Find the QR code in the room or area where the issue is located. This QR code could be labeled with a message like "Scan if you need help with maintenance."

Scan the QR Code: Use your smartphone or tablet to scan the QR code. This will direct you to the Click Maint CMMS work order submission page for that specific location.

-

3

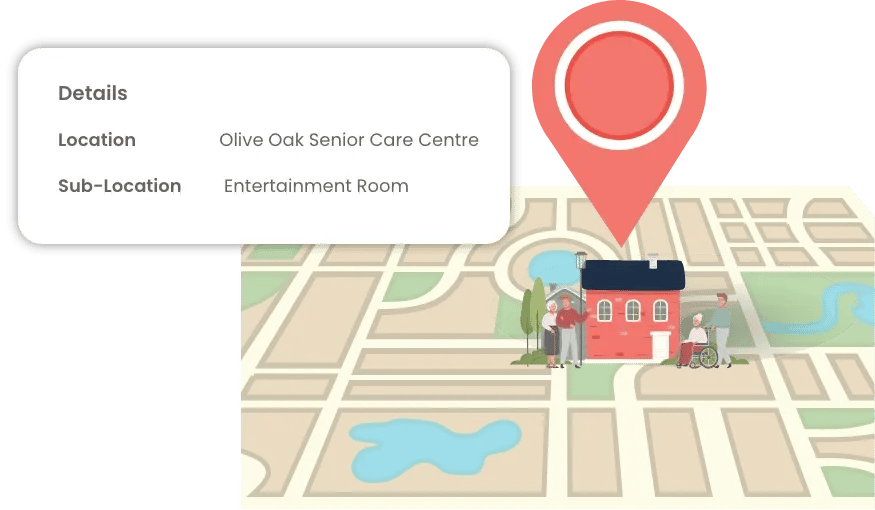

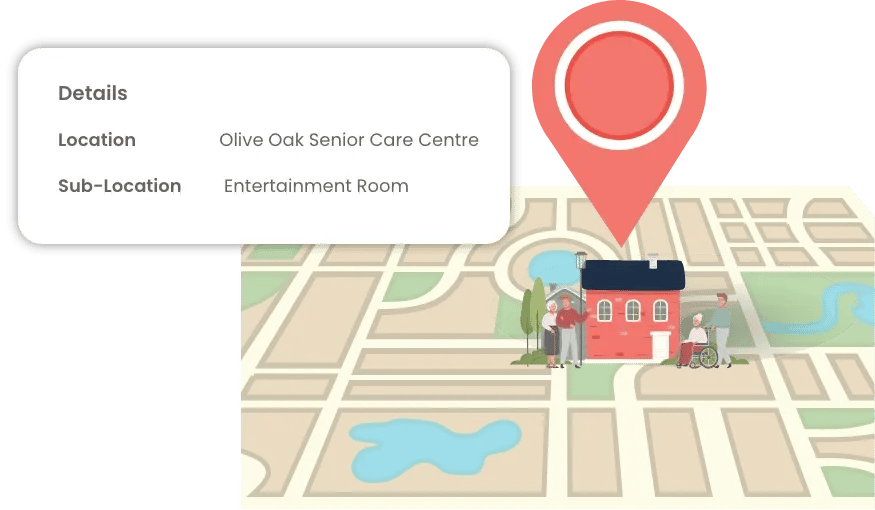

Access the Work Order Submission Form

Open Click Maint App: If prompted, open the Click Maint App on your device.

Auto-fill Location Details: The scanned QR code will automatically fill in the location and sub-location details of the issue.

-

4

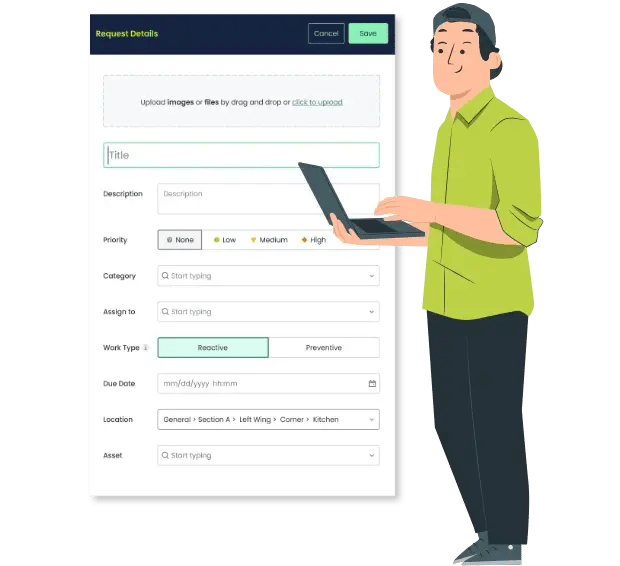

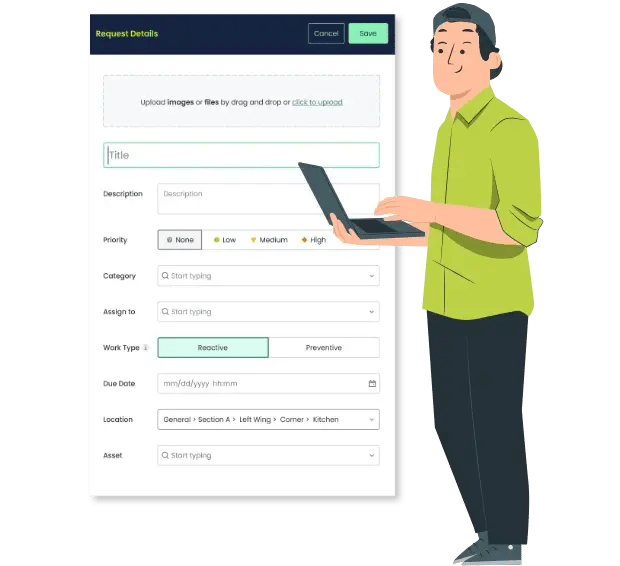

Fill in the Work Order Details

Describe the Issue: Provide a detailed description of the maintenance issue. Be specific about what needs to be addressed, such as "There is a spill on the floor near the entrance."

Attach Photos: When possible, attach photos of the issue to give maintenance staff a clear understanding of the problem.

-

5

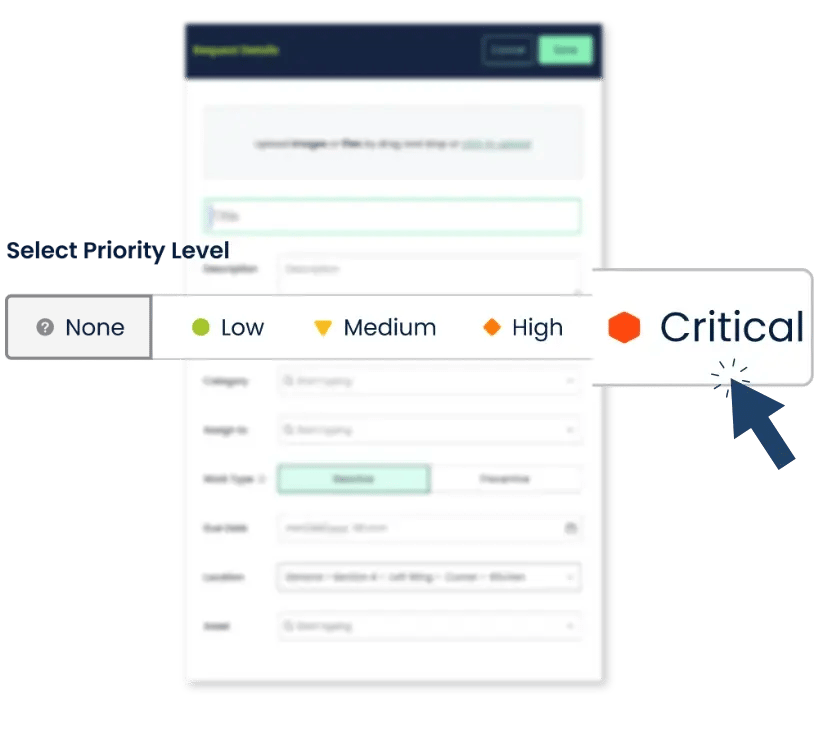

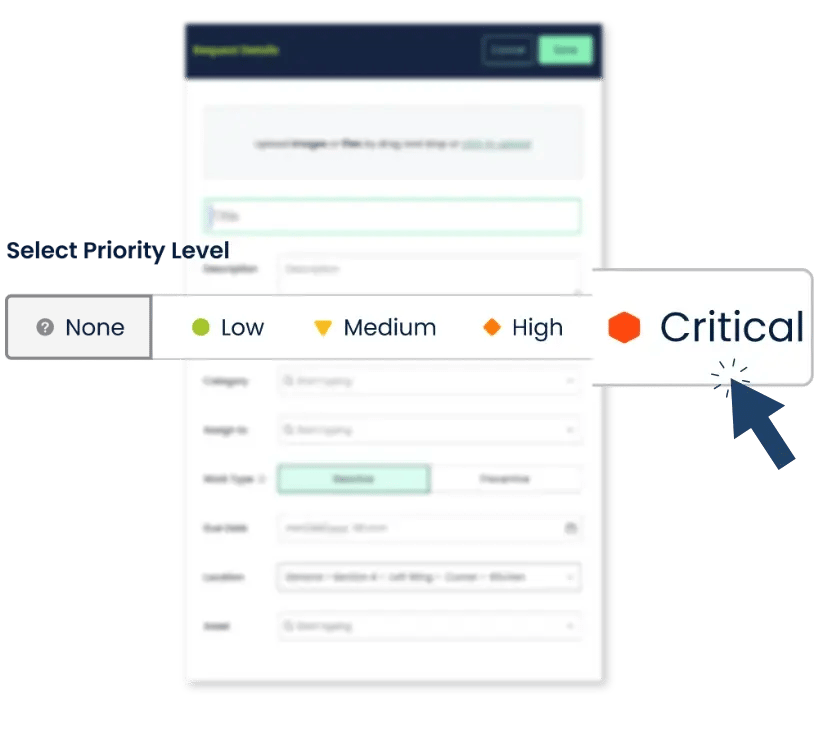

Select Priority Level

Set Priority: Choose the priority level for the work order (e.g., low, medium, high). For urgent issues like a spill, select a higher priority to ensure prompt attention.

-

6

Submit the Work Order

Review Information: Double-check all the information entered to ensure accuracy.

Submit Request: Click the "Submit" button to send the work order request to the maintenance team.

-

7

Confirmation and Tracking

1. Fill in the required information, such as equipment name, asset ID, Part number, location name, serial number, or URL.

2. Click on the ‘Generate’ button to generate the QR Code.

-

8

Follow Up

Check Notifications: Stay updated with notifications from the Click Maint App about the progress and completion of the work order.

Verify Resolution: Once notified that the work order is completed, check to ensure the issue has been resolved satisfactorily.

Identify the Issue

Observation: Notice a maintenance issue that needs attention, such as a spill in a room.

Scan the QR Code

Locate QR Code: Find the QR code in the room or area where the issue is located. This QR code could be labeled with a message like "Scan if you need help with maintenance."

Scan the QR Code: Use your smartphone or tablet to scan the QR code. This will direct you to the Click Maint CMMS work order submission page for that specific location.

Access the Work Order Submission Form

Open Click Maint App: If prompted, open the Click Maint App on your device.

Auto-fill Location Details: The scanned QR code will automatically fill in the location and sub-location details of the issue.

Fill in the Work Order Details

Describe the Issue: Provide a detailed description of the maintenance issue. Be specific about what needs to be addressed, such as "There is a spill on the floor near the entrance."

Attach Photos: When possible, attach photos of the issue to give maintenance staff a clear understanding of the problem.

Select Priority Level

Set Priority: Choose the priority level for the work order (e.g., low, medium, high). For urgent issues like a spill, select a higher priority to ensure prompt attention.

Submit the Work Order

Review Information: Double-check all the information entered to ensure accuracy.

Submit Request: Click the "Submit" button to send the work order request to the maintenance team.

Confirmation and Tracking

1. Fill in the required information, such as equipment name, asset ID, Part number, location name, serial number, or URL.

2. Click on the ‘Generate’ button to generate the QR Code.

Follow Up

Check Notifications: Stay updated with notifications from the Click Maint App about the progress and completion of the work order.

Verify Resolution: Once notified that the work order is completed, check to ensure the issue has been resolved satisfactorily.

Implementing CMMS in Retirement Homes

Assessment and Planning

Conducting a Needs Assessment

Before implementing a computerized maintenance management system (CMMS) in a retirement facility, it's important to conduct a comprehensive needs assessment. This involves evaluating the current maintenance processes, identifying pain points, and understanding the specific requirements of the facility. Key areas to assess include asset management, work order processes, preventive maintenance schedules, and compliance requirements. Gathering input from maintenance staff, management, and other stakeholders helps identify gaps and areas for improvement.

Setting Goals and Objectives

Once the needs assessment is complete, the next step is to set clear goals and objectives for the CMMS implementation. These goals should align with the overall mission of the retirement home and address the identified needs. Objectives may include improving response times for maintenance requests, reducing equipment downtime, enhancing compliance tracking, and increasing overall operational efficiency. Setting measurable goals provides a clear roadmap for the implementation process and helps in evaluating the success of the CMMS.

Choosing the Right CMMS

Evaluating Different CMMS Solutions

Selecting the right CMMS solution is critical for successful implementation. Start by researching and evaluating different CMMS options available in the market. Consider the specific features and functionalities each system offers and how well they align with the needs of the retirement home facility. Key features to look for include request management, work order management, preventive maintenance scheduling, asset tracking, inventory management, and mobile access.

Key Considerations for Selection

When choosing a CMMS, consider the following factors:

- Ease of Use: The system should have a user-friendly interface that staff can easily navigate.

- Scalability: Ensure the CMMS can grow with the facility’s needs and accommodate future expansions.

- Customization: Look for a system that allows customization to match the specific workflows and processes of the retirement home.

- Integration: Check if the CMMS can integrate with other existing systems, such as accounting and HR software.

- Support and Training: Evaluate the vendor’s support services and training programs to ensure staff can quickly adapt to the new system.

Training and Onboarding

Training Staff on the New System

Effective training is essential for the successful implementation of a CMMS. Click Maint customer success and onboarding staff can help you develop a comprehensive training program that covers all aspects of the new system. Training will be customized for different user roles, ensuring that maintenance staff, managers, and other relevant personnel are proficient in using the system. Virtual training sessions, articles, and online tutorials will enhance the learning experience.

Ensuring Smooth Onboarding and Adoption

To facilitate a smooth onboarding process, we recommend a phased implementation approach. Start with a pilot program in one department or area of the facility to test the system and gather feedback. Use the insights gained to make necessary adjustments before rolling out the CMMS across the entire facility. We will encourage staff to provide feedback and promptly address any concerns. Regular follow-up sessions and ongoing support will help maintain momentum and ensure successful adoption.

Monitoring and Optimization

Regularly Reviewing System Performance

Once the CMMS is implemented, it’s important to conduct performance reviews regularly. Our reports help you monitor key maintenance metrics such as work order completion times, equipment downtime, maintenance costs, and more. Regular performance reviews will identify areas where the system excels and highlight areas that may need improvement.

Continuous Improvement Through Feedback and Updates

Implementing a CMMS is an ongoing process that requires continuous improvement. We will encourage staff to provide ongoing feedback on the system’s performance and usability. This feedback will be used to make necessary updates and enhancements to the CMMS. Regular software updates and training refreshers will ensure the system remains current and continues to meet the evolving needs of the retirement home.