CMMS Software for Energy & Utilities Companies

Maximize uptime through effective preventive maintenance

No credit card required | Start your 30 day FREE trial

- CMMS

- Industry

- CMMS Software for Energy & Utilities Companies

Labor Efficiency Improvement

Estimated Downtime Reduction

Inventory Optimization

Trusted by thousands of maintenance & facilities professionals

How much does a CMMS cost?

Try our Price Calculator to get an Instant Estimate for Your Use Case

PROFESSIONAL PLAN

$ 42 USD

PER USER PER MONTH

$ 35 USD

PER USER PER MONTH

Utilities Maintenance Pain Points

Unexpected equipment failures

High unplanned downtime costs

Workforce Challenges

Environmental and Regulatory Compliance

Integration of New Technologies

Budget Constraints

How CMMS Solves these Challenges

Automated work order management

Asset downtime tracking

Maintenance history reporting

Labor and cost tracking

Inventory management and optimization

Automated preventive maintenance scheduling

Click Maint CMMS Features for the Energy & Utilities Industry

Click Maint CMMS is designed to meet the specific needs of the Energy & Utilities sector, offering a suite of features to streamline operations, enhance asset performance, and optimize maintenance processes.

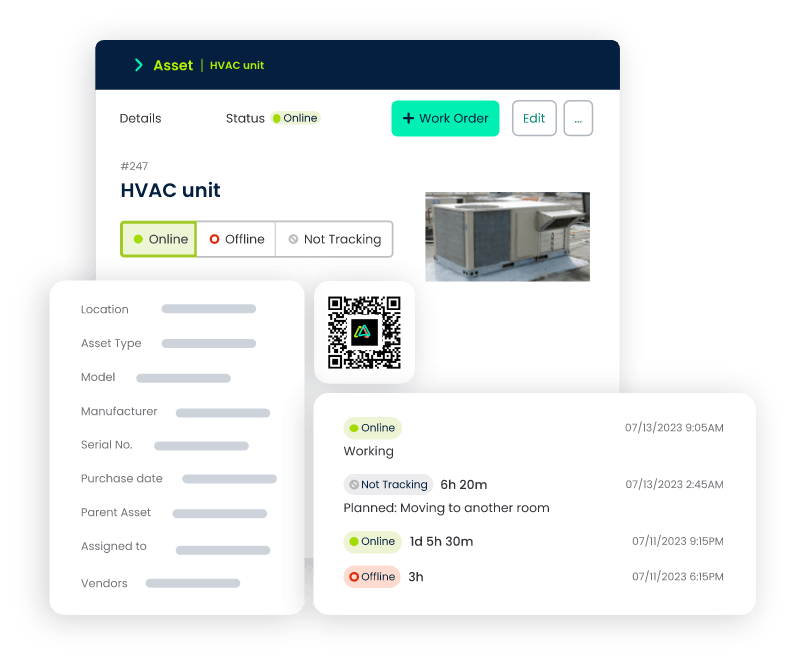

Asset Management

Efficiently manage your extensive portfolio of energy and utility assets with Click Maint CMMS.

- Centralized Repository: Benefit from a centralized repository within Click Maint CMMS that catalogs and tracks all energy and utility assets, ensuring efficient resource allocation, reduced downtime, and easy access to maintenance history.

- Easy Identification: Quickly locate assets within vast energy and utility infrastructures, reducing downtime during maintenance activities. Access detailed maintenance history for each asset, aiding in informed decision-making and optimizing maintenance strategies. Keep tabs on warranties associated with energy and utility assets, facilitating timely claims and replacements to ensure continuous operations.

- Cost Control: Avoid unexpected expenses by planning and budgeting for asset replacements, supporting effective financial planning within the energy and utilities sector.

- Modernization: Keep energy and utility facilities up-to-date with the latest technologies and safety standards, ensuring compliance with industry advancements.

- Performance Optimization: Continuously assess and upgrade assets for improved performance, enhancing the reliability of critical systems.

- Sustainability: Plan for eco-friendly asset replacements that align with sustainability goals, contributing to environmentally conscious operations.

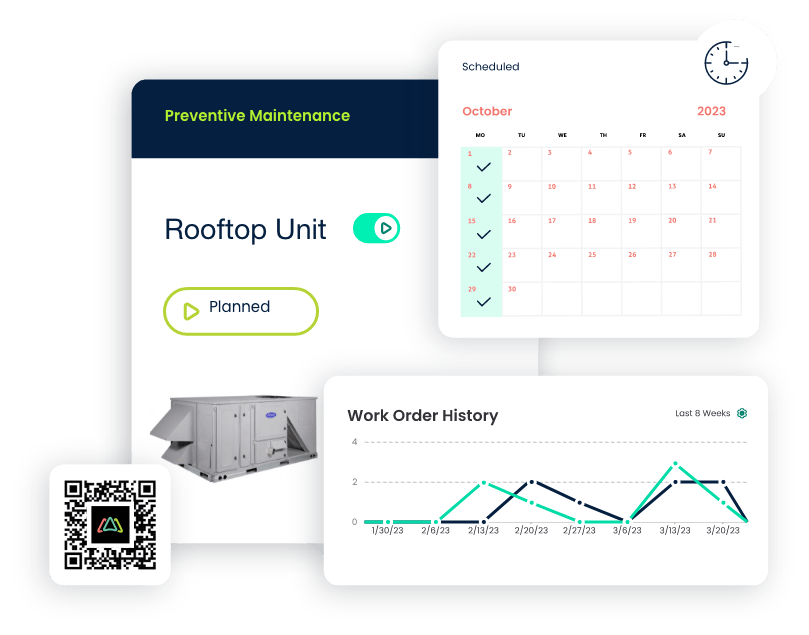

Preventive Maintenance

Take a proactive approach to maintenance with Click Maint CMMS's preventive maintenance capabilities.

- Reduced Breakdowns: Minimize unexpected equipment failures during critical operations and high-demand periods.

- Improved Reliability: Enhance the reliability of critical energy and utility systems and equipment through proactive maintenance planning.

- Predictable Costs: Budget for maintenance expenses and avoid costly emergency repairs, ensuring financial predictability.

- Regulatory Compliance: Ensure compliance with safety and industry standards specific to the energy and utilities sector.

- Improved Safety: Regular inspections and maintenance mitigate safety risks associated with energy and utility operations.

- Improved Experience: Well-maintained facilities lead to positive experiences for patrons, ensuring satisfaction and trust.

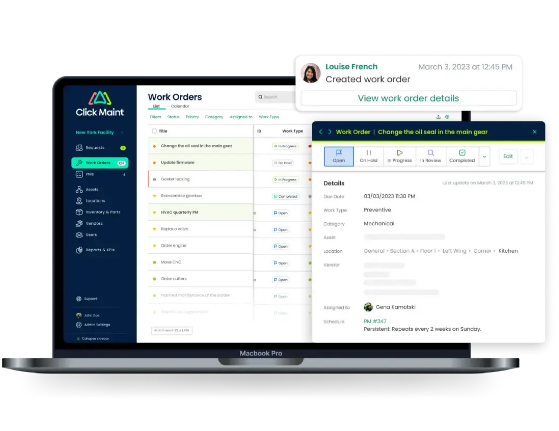

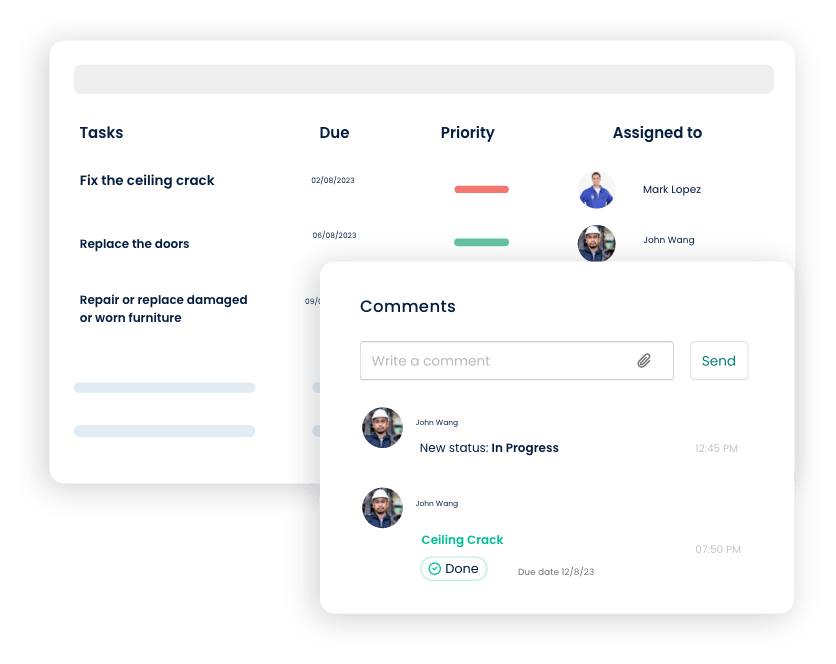

Work Order Management

Streamline maintenance workflows with Click Maint CMMS's intuitive Work Order Management system.

- Quick Response: Accelerate the resolution of maintenance requests, minimizing disruptions within energy and utility operations.

- Transparency: Maintain clear documentation of work orders and their status for accountability and compliance purposes.

- Prioritization: Assign priority levels to work orders based on urgency and importance, optimizing resource allocation.

- Audit Trails: Keep a comprehensive record of all maintenance activities for accountability and compliance within energy and utilities.

- Task Accountability: Assign specific responsibilities to maintenance personnel to ensure efficient task execution.

- Task Tracking: Monitor task status and completion in real-time, facilitating prompt issue resolution.

- Resource Allocation: Efficiently allocate human and material resources to maximize operational efficiency within energy and utility facilities.

- Improved Coordination: Enhance coordination between maintenance teams, vendors and contractors to streamline operations within energy and utilities.

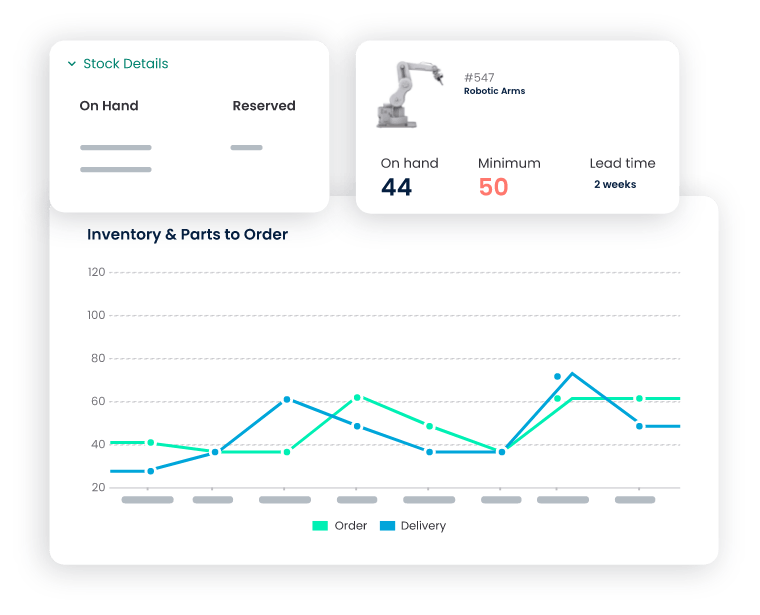

Inventory Management

Optimize your spare parts inventory with Click Maint CMMS’s user-friendly Inventory Management features.

- Real-Time Visibility: Monitor inventory levels in real time, reducing the risk of shortages during energy and utility maintenance.

- Inventory Optimization: Minimize carrying costs while ensuring the availability of critical items, optimizing inventory efficiency.

- Data-Driven Decisions: Utilize inventory data for budgeting and cost control within energy and utility operations.

- Reduced Downtime: Ensure necessary parts are always available to minimize equipment downtime within energy and utility facilities.

- Cost Savings: Avoid overstocking or understocking, optimizing inventory costs for energy and utilities.

- Supplier Management: Streamline relationships with suppliers and vendors for efficient procurement within the energy and utilities sector.

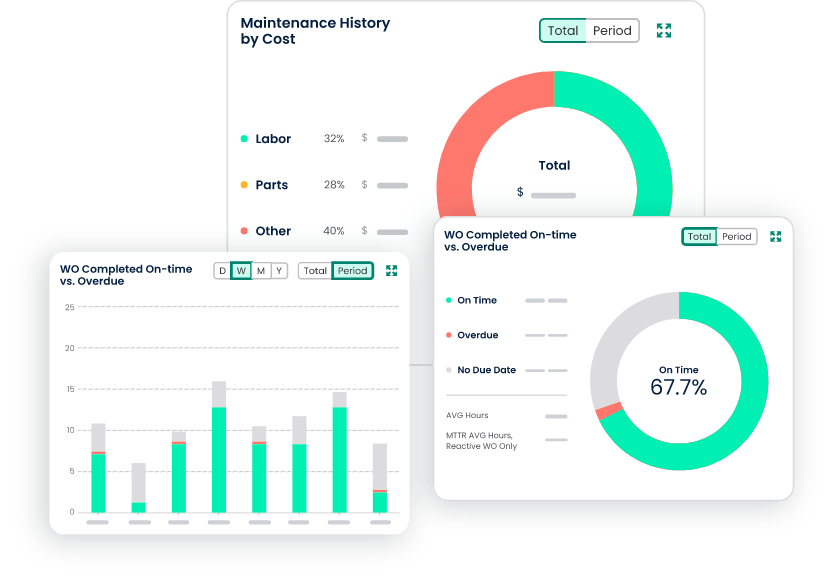

Reporting and Analytics

Empower your decision-making with Click Maint CMMS's comprehensive Reporting and Analytics tools.

- Data Accessibility: Access relevant maintenance data in an organized and digestible format, promoting efficient decision-making within energy and utilities.

- Performance Analysis: Analyze asset performance and maintenance trends to optimize strategies within energy and utility operations.

- Compliance Reporting: Generate reports for regulatory compliance and auditing purposes specific to the energy and utilities sector.

- Cost Analysis: Evaluate maintenance costs and identify areas for cost reduction within energy and utilities operations.

- Resource Optimization: Identify areas where resources can be reallocated for efficiency, maximizing operational effectiveness.

- Continuous Improvement: Analyze data to continuously improve maintenance strategies tailored for the energy and utilities industry.

- Performance Benchmarking: Compare maintenance performance against industry benchmarks, ensuring continuous enhancement within energy and utility operations.

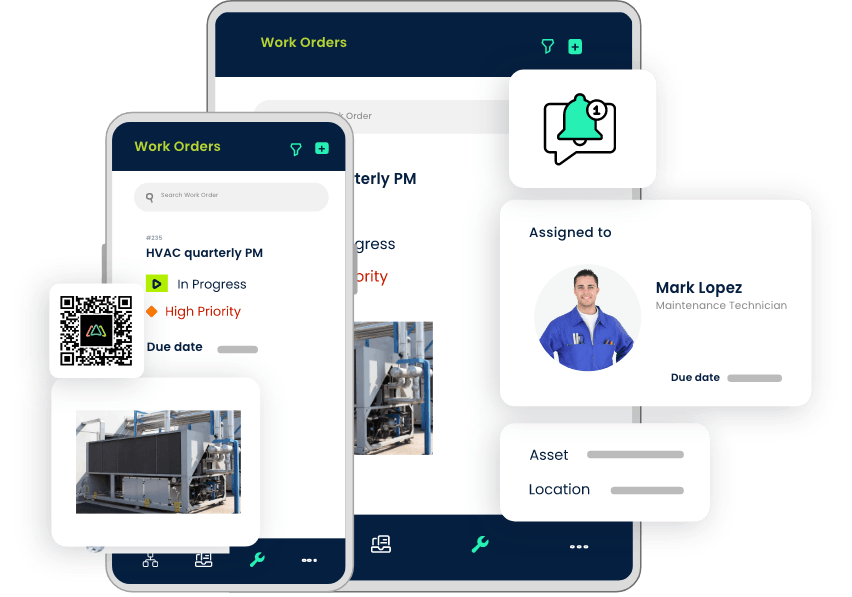

Mobile Accessibility: Facility Management on the Go!

Drive efficiency with mobile accessibility, providing maintenance teams the flexibility to access and manage critical tasks, asset information, and work orders from their mobile devices.

Real-Time Information Access

Access vital maintenance information in real-time, irrespective of your physical location within the energy and utilities facility. Technicians can retrieve data, check asset details, and access work orders instantly, whether they are in the field, at a power station, or navigating through expansive utility infrastructure. This real-time access enhances response times and facilitates more efficient issue resolution.

On-the-Go Work Order Management

Empower utility maintenance personnel to create, update, and complete work orders directly from their mobile devices. This on-the-go work management ensures that maintenance tasks are promptly addressed, even during critical operations or high-demand periods. Mobile access eliminates the need for manual paperwork, reducing administrative overhead.

QR Code Scanning and Image Capture

Enable staff to leverage mobile devices for scanning asset QR codes or capturing photos of equipment. This functionality simplifies asset identification and allows for comprehensive condition documentation, ensuring a thorough maintenance record for critical energy and utility assets.

Offline Access

Recognizing that network connectivity may be unreliable, especially in remote or challenging areas within the energy and utilities sector, mobile CMMS solutions offer offline access. This feature allows users to continue working on tasks even when not connected to the internet. Once connectivity is restored, the system seamlessly syncs data, ensuring continuity in maintenance operations.

Improved Collaboration

Promote enhanced communication and collaboration among energy and utilities maintenance teams. Team members can share updates, access shared documents, and collaborate on tasks using their mobile devices. This real-time collaboration ensures alignment among team members, contributing to more efficient and synchronized maintenance operations across expansive energy and utility facilities.

Experience Click Maint CMMS now

30-Day Free Trial

No Credit Card needed.

Instant access to all features & modules with an optional live walk-through with a Click Maint expert

Book a live Demo

In this 30-minute demo, see firsthand how our easy CMMS can streamline your operations, enhance productivity, and reduce downtime.

Overview of Energy and Public Utilities Facilities

Energy and utilities facilities play an important role in powering regions and providing essential services. These facilities include infrastructure designed for generating, transmitting, and distributing energy and providing water and other utility services.

Power Generation Plants

- Types: Energy facilities include power generation plants, which can be categorized into coal, natural gas, nuclear, hydroelectric, wind, solar, and geothermal.

- Functions: These plants convert various energy sources into electricity, contributing to the overall energy grid.

Transmission and Distribution Networks

- Transmission: High-voltage transmission lines transport electricity over long distances from power plants to local distribution centers.

- Distribution: Lower-voltage lines distribute electricity to homes, businesses, and other end-users.

Renewable Energy Installations

- Solar Farms: Large-scale installations of solar panels harness sunlight to generate electricity.

- Wind Farms: Array of wind turbines convert wind energy into electrical power, contributing to sustainable energy production.

Natural Gas Facilities:

- Extraction: Facilities for extracting natural gas from underground reservoirs.

- Processing: Processing plants refine and purify natural gas for distribution and consumption.

Nuclear Power Plants

- Generation: Nuclear facilities use controlled nuclear reactions to generate heat, producing steam that drives turbines for electricity generation.

- Safety Measures: Stringent safety measures are in place to prevent nuclear accidents and ensure the safe disposal of radioactive waste.

Hydroelectric Facilities

- Dams and Reservoirs: Dams are constructed to harness the energy of flowing water, creating reservoirs that feed hydroelectric power plants.

- Turbines and Generators: Water flowing through turbines generates electricity in hydroelectric facilities.

Utility Services Facilities

- Water Treatment Plants: Facilities that purify and distribute potable water to residential, commercial, and industrial users.

- Wastewater Treatment Plants: Essential for treating and purifying wastewater before it is released back into the environment.

Smart Grid Technologies

- Integration: Modern facilities are increasingly adopting smart grid technologies to enhance efficiency, reliability, and sustainability.

- Distributed Energy Resources (DERs): Integration of renewable energy sources, energy storage, and advanced monitoring systems.

Energy Storage Facilities

- Battery Storage: Facilities with large-scale battery systems for storing excess energy generated during periods of low demand for later use.

Research and Innovation Centers

- Advancements: Facilities dedicated to research and development, driving innovation in energy generation, storage, and distribution.

See how affordable Click Maint CMMS is

Benefits of Using CMMS for Energy and Public Utility Companies

Implementing a Computerized Maintenance Management System (CMMS) can be transformative for energy and public utility companies, offering a wide range of benefits that enhance operational efficiency, reduce downtime, and ensure compliance with industry regulations. Here are some key advantages:

Streamlined Maintenance Processes

- Efficiency Boost: CMMS facilitates the automation of routine maintenance tasks, reducing manual efforts and streamlining processes.

- Optimized Workflows: Work orders, scheduling, and resource allocation become more efficient, allowing maintenance teams to focus on critical tasks.

Preventive Maintenance

- Reduced Downtime: CMMS enables the implementation of preventive and predictive maintenance strategies, minimizing the risk of equipment failures and unexpected downtime.

- Extended Asset Lifespan: Regular monitoring and timely maintenance ensure that assets operate at peak performance, extending their lifespan.

Real-Time Data and Reporting

- Data-Driven Decision-Making: CMMS provides real-time insights into asset health, work order status, and maintenance costs, empowering decision-makers with accurate and up-to-date information.

- Comprehensive Reporting: Robust reporting capabilities help in analyzing historical data, identifying trends, and making informed decisions for future maintenance planning.

Improved Asset Management

- Asset Visibility: CMMS offers centralized visibility into all assets, their condition, and maintenance history, facilitating effective asset management.

- Optimized Inventory: Inventory management features help in controlling stock levels, minimizing surplus parts, and ensuring that necessary components are available when needed.

Enhanced Workforce Productivity

- Task Prioritization: CMMS assists in prioritizing maintenance tasks, ensuring that critical issues are addressed promptly.

- Resource Optimization: Efficient scheduling and resource allocation lead to better utilization of workforce skills and time.

Mobile Accessibility

- Field Service Management: Most CMMS platforms provide mobile applications, enabling field technicians to access work orders, update information, and receive real-time notifications wherever they are working.

- Flexibility and Agility: Mobile accessibility enhances the flexibility and agility of maintenance teams, especially in large and geographically dispersed operations.

Compliance and Regulatory Adherence

- Documentation and Traceability: CMMS maintains detailed records of maintenance activities, supporting compliance audits and regulatory adherence.

- Automated Compliance Checks: Automated features help ensure that maintenance activities align with industry standards and regulations.

Cost Savings and Budget Control

- Optimized Resource Allocation: CMMS aids in optimizing resource allocation, preventing overstaffing or underutilization of resources.

- Predictable Maintenance Costs: By implementing preventive strategies, CMMS helps in predicting and controlling maintenance costs, preventing unexpected costs.

Cybersecurity Measures

- Data Security: Modern CMMS solutions incorporate robust cybersecurity measures to protect sensitive maintenance data from unauthorized access and cyber threats.

- System Integrity: Ensuring the integrity of the CMMS system contributes to the overall cybersecurity posture of the organization.

Continuous Improvement

- Feedback Loops: CMMS allows for the collection of feedback from maintenance activities, creating opportunities for continuous improvement.

- Adaptability: The ability to adapt maintenance strategies based on historical data and performance metrics contributes to ongoing operational enhancement.

Maintenance Challenges Specific to Energy & Public Utility Companies

The energy and public utility sector faces unique maintenance challenges due to the critical nature of its infrastructure and the essential services it provides to communities.

|

Maintenance Challenge |

Issue |

Description |

|---|---|---|

|

Aging Infrastructure |

Many utility companies operate with aging infrastructure, including power plants, pipelines, and water treatment facilities. |

Aging equipment requires more frequent maintenance, and sourcing spare parts becomes a challenge as manufacturers may discontinue production. |

|

Regulatory Compliance |

Stringent regulations govern the energy and utility sector to ensure safety, environmental protection, and operational standards. |

Adhering to complex and evolving regulations necessitates meticulous maintenance planning and documentation to meet compliance requirements. |

|

Preventive and Predictive Maintenance |

Balancing preventive and predictive maintenance is essential for avoiding unexpected failures and minimizing downtime. |

Implementing predictive maintenance technologies requires significant investment and expertise, and determining the optimal maintenance strategy can be challenging. |

|

Workforce Skill Shortages |

The specialized nature of energy and utility equipment demands a skilled workforce. |

Recruiting and retaining skilled technicians, engineers, and maintenance personnel can be challenging, especially as experienced professionals retire. |

|

Critical Asset Management |

Managing critical assets such as transformers, generators, and water treatment plants is essential for uninterrupted service. |

Balancing the need for continuous operation with scheduled maintenance of critical assets to prevent catastrophic failures. |

|

Environmental and Weather Challenges |

Energy and utility facilities are exposed to harsh environmental conditions and weather extremes. |

Ensuring infrastructure resilience to environmental challenges and implementing weather-dependent maintenance strategies. |

|

Cybersecurity Threats |

Increased digitalization and connectivity expose energy and utility companies to cybersecurity threats. |

Protecting critical infrastructure from cyberattacks requires ongoing investment in cybersecurity measures and employee training. |

|

Emergency Response and Disaster Recovery |

Natural disasters or unforeseen emergencies can damage infrastructure and disrupt services. |

Developing and regularly testing emergency response and disaster recovery plans to minimize downtime and ensure rapid recovery. |

|

Asset Tracking and Data Management |

Large-scale utility operations involve numerous assets spread across vast geographical areas. |

Implementing effective asset tracking systems and managing vast amounts of maintenance data for informed decision-making. |

|

Budget Constraints |

Utility companies often operate within tight budget constraints. |

Balancing the need for regular maintenance, equipment upgrades, and infrastructure improvements within limited financial resources. |

Why Traditional Maintenance Approaches Fall Short

Traditional maintenance approaches, such as paper-based systems and spreadsheets, fall short in meeting the complex needs of maintenance in energy and public utility companies for several reasons:

|

Challenge |

Paper-Based Systems |

Spreadsheets |

|---|---|---|

|

Limited Accessibility |

Physical or localized access |

Limited to specific computers |

|

Data Silos and Inefficiency |

Fragmented and decentralized |

Challenges in data retrieval |

|

Lack of Real-Time Updates |

Relies on manual updates |

May not provide real-time data |

|

Limited Collaboration and Communication |

Lack of collaboration features |

Cumbersome collaboration |

|

Error-Prone Manual Processes |

Susceptible to human errors |

Manual data entry risks inaccuracies |

|

Inadequate Reporting and Analysis |

Labor-intensive reporting |

Difficulty in in-depth analysis |

|

Limited Scalability |

Struggles with large-scale operations |

May become inefficient as volume grows |

|

Security Concerns |

Prone to loss, damage, or unauthorized access |

Limited data security measures |

|

Difficulty in Compliance Management |

Challenges in traceability and documentation |

May struggle to meet compliance requirements |

|

Inefficiencies in Work Order Management |

Manual tracking leads to inefficiencies |

Delays in work order management |

Best Practices for Successful CMMS Adoption

Executive Leadership Support

Secure strong support from executive leadership to ensure that CMMS adoption is prioritized at all organizational levels.

Cross-Functional Team Involvement

Involve representatives from various departments, including maintenance, IT, and compliance, to ensure a holistic and collaborative approach to CMMS implementation.

Thorough Training Programs

Provide comprehensive training programs for all users to maximize utilization and understanding of the CMMS platform.

Data Quality Assurance

Implement stringent data quality assurance measures to ensure the accuracy and reliability of information within the CMMS.

Continuous Improvement Initiatives

Establish a culture of continuous improvement, regularly reviewing and optimizing CMMS processes to adapt to changing energy and utility needs.

User Feedback Mechanisms

Establish mechanisms for collecting feedback from CMMS users to identify areas of improvement and address user-specific challenges.

Regular Audits and Assessments

Conduct regular audits and assessments of CMMS performance, compliance, and security measures to identify and address potential issues proactively.

Scalability Planning

Plan for scalability by choosing a CMMS solution that can grow alongside the expanding infrastructure of the energy and utilities sector.