From Chaos to Clarity: Online Strategies for User Adoption Success of Maintenance Software

Are you planning to adopt maintenance management software in your business operations? If you are (or you’ve started to roll out), you’ll soon realize it’s not as simple as one might think. Mostly, there will be resistance, especially regarding user adoption.

Still, with user adoption challenges, training requirements, and all you need to do to implement new solutions to improve your operation, it’s not impossible. In this article, we’ll look at common user adoption challenges and the best strategies to ace CMMS software adoption in your organization.

What is Maintenance Software, and What Can They Do?

Maintenance software, more well-known as Computerized Maintenance Management System (CMMS), is designed to help businesses with their maintenance activities. It helps manage, schedule, and track these projects and tasks more efficiently and accurately than manual systems.

CMMS software can serve various industries, including manufacturing, healthcare, hospitality, and education. They can also work well for small businesses. These tools are reliable solutions because they provide a centralized platform for maintenance operations.

Key Functionalities

What do you use a CMMS for? Here are some key functionalities and benefits of maintenance software:

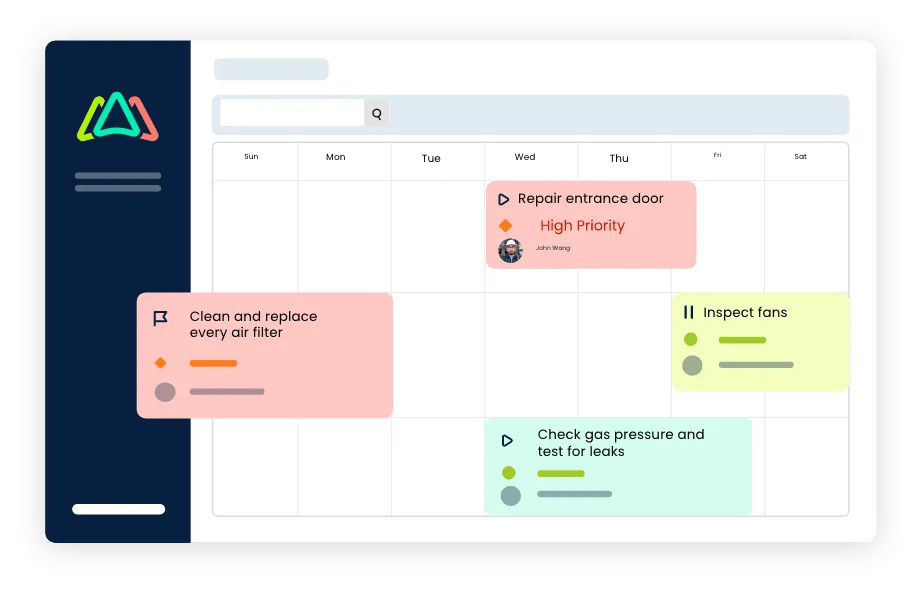

- Maintenance Scheduling and Planning: CMMS can automate your company's preventive and predictive maintenance scheduling, reducing equipment downtime and extending asset life. Some tasks your CMMS can help you with include calendar-based scheduling, condition monitoring, and alerts for upcoming maintenance tasks.

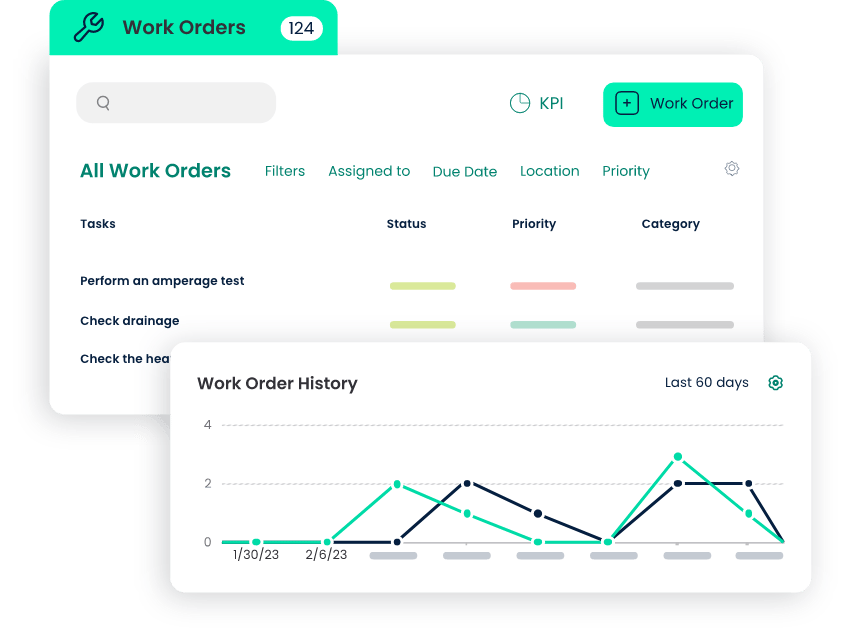

- Work Order Management: With a maintenance solution, users can also create, assign, track, and close work orders for maintenance tasks. Companies often use this function to streamline processes like managing repair tasks. They can also track parts usage, labor hours, and associated costs.

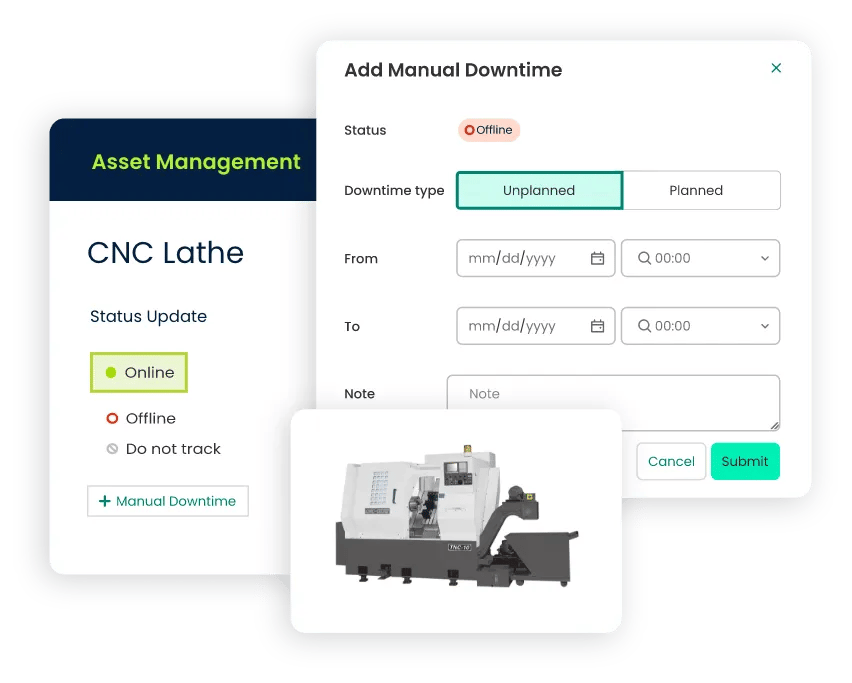

- Asset Management: A CMMS provides a comprehensive view of all assets, including equipment and buildings. Use it to track their condition, maintenance history, and performance.

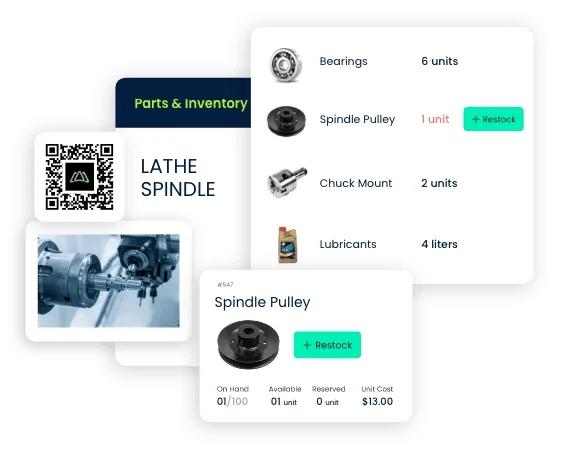

- Inventory Control: Maintenance management software helps manage spare parts inventory to ensure you always have critical parts in stock. It can also track parts usage, reorder levels, and suppliers.

What Adoption Rate Should I Shoot For?

When you implement any software, you want to make sure that you have high adoption rates. That’s the rate at which users and stakeholders (i.e. your staff, customers, and managers) use the software. As a rule of thumb, you want to reach around a 70- 80% adoption rate. In some cases, you can even shoot for 90% or above.

Common User Adoption Challenges

So, if CMMS software is such a great solution, why do some companies deal with adoption challenges? Here are some common challenges you might face and what they might look like:

1) Resistance to Change

Employees may be reluctant to shift from familiar, manual, or semi-automated processes to a new, fully digital system. This resistance can be due to various reasons, including some of these common ones:

- Uncertainty about how the new system will work and its impact on daily routines can make employees apprehensive.

- Workers might worry that automation and efficiency gains could lead to job reductions or significant role changes.

- If the current methods are perceived as "good enough," there may be little perceived need for a change, especially if those methods have been in place for a long time.

- Employees may not see the value in adopting new software without a clear understanding of how it will make their jobs easier or benefit the organization.

2) Lack of Training and Support

Another significant hurdle to adoption is when employees feel they haven't been given the necessary training to use the new system effectively or lack post-implementation support. Most specifically, these issues might come up:

- Maintenance management software can be complex, and if users find it difficult to navigate or understand, they might revert to old habits or use the software minimally.

- Training sessions don't cover all features relevant to each user's role or become too generic, leaving users unprepared.

- After the initial rollout, users may encounter issues or have questions. A lack of accessible, responsive support can hinder their ability to use the software effectively.

3) Poor System Selection

While selecting a system that fits your budget is important, many other factors are involved. Choosing maintenance software that doesn't align with the organization's needs, workflows, and processes can lead to adoption challenges.

Here are some system selection issues that might arise:

- If the software doesn't fit well with existing business processes or requires significant changes to workflows without clear benefits, users may be resistant or slow to adopt.

- Selecting complex software or one with many unnecessary features can frustrate your team.

- Software that cannot be customized to fit the organization's specific requirements or does not integrate well with existing systems can limit its usefulness and acceptance.

4) Technical Limitations and Infrastructure

The existing technical infrastructure may not fully support the effective use of the new maintenance software, presenting a barrier to user adoption.

- If the organization's hardware is not up to date, it may be unable to run the new software efficiently, leading to slow performance and user frustration.

- Poor internet connectivity can severely limit access and functionality for cloud-based maintenance software, discouraging users.

- In environments where mobile access matters, not having a compatible mobile solution can challenge field personnel to use the software effectively.

Strategies to Improve Maintenance Software Adoption in Your Company

When implementing your maintenance software, follow these strategies for better results:

1) Involve Users Early and Often

Involving users from the outset will help you find maintenance software that meets the organization's needs. Remember that your staff will be the main stakeholders in this endeavor, so they should be part of the selection process.

Try getting representatives from various departments and levels early in the selection and implementation process and establishing channels for continuous feedback. This way, the system’s future users— your employees— can express their concerns and suggest improvements.

2) Create Tailored Training Programs

Most systems have training modules ready, but they might not be enough. For effective software adoption, you should consider developing training programs tailored to the specific roles and responsibilities within the organization.

Training should address the unique needs of different user groups and include interactive and hands-on learning experiences to make it engaging enough to be completed. When training is helpful and engaging, completion rates and adoption will increase.

3) Communicate Benefits Clearly

Communication is the crux of your adoption process, and what you communicate matters. That means you need to clearly articulate the “why” and not just the “what,” meaning the benefits of the maintenance software for the organization and the individual users in their daily tasks.

Share success stories and case studies from other organizations with similar systems. Talk about how the tool could lead to fewer hours of work, more sales commissions, and other intrinsic benefits to staff. It’s okay for them to ask, “What’s in it for me? Ultimately, these systems should serve everyone.

4) Provide Adequate Support

Establishing a responsive support system should help address users' issues or questions. This can include setting up a help desk or online forum where users can get assistance quickly. For the most part, you should find a CMMS provider with dedicated accounts managers if possible.

Additionally, identifying and training peer champions or super-users who can support and encourage their colleagues can enhance user adoption and confidence in using the new system.

5) Manage Change Effectively

You probably need to complete this big action point if you haven’t heard of a change management plan. It’s a strategy for change that outlines timelines, responsibilities, and milestones—the transition to the new software.

For those unfamiliar, many top programs on change management and project planning are now widely available through online accredited universities, making it accessible to upskill your team in these essential areas. With the right guidance and resources, your team can adapt seamlessly.

This simple document will show everyone the whole adoption process. Place this somewhere for everyone to see, like an office bulletin or a project management software. Hire a change manager or project manager with management degrees or certifications from accredited online universities to manage this process for you. This ensures a structured and professional approach to change, allowing your team to handle transitions smoothly and minimize disruptions.

Digital Adoption Now

There’s been so much buzz around digital adoption lately. However, it goes without saying that it’s not always as easy as it seems. Around 70% of digital adoption projects fail. Still, it should be part of our priority. The new revolution will rely greatly on these solutions. There might be friction initially, but the benefits will far outweigh the hurdles once you get through the user adoption phase.

TABLE OF CONTENTS

Keep Reading

Ever find yourself checking into a luxury hotel and expecting a relaxing stay, only to find a ...

11 Apr 2025

Organizations are witnessing swift changes in the business environment and confronting a ...

8 Apr 2025

Last month, news outlets and the entire internet was abuzz with the return of NASA astronauts ...

3 Apr 2025

What comes first - CMMS or predictive maintenance? If your answer is either, it is correct. ...

28 Mar 2025

Artificial intelligence (AI) talk has become commonplace. Today, engaging in business-focused ...

27 Mar 2025

Imagine a world where machines predict, diagnose, and fix their issues before they fail. This ...

25 Mar 2025

A facility maintenance plan is at the core of a facility’s operations. This organized ...

21 Mar 2025

Think of managing your maintenance operations like managing a championship sports team. Just ...

21 Mar 2025

The maintenance sector is battling a severe talent shortage that threatens to undermine ...

7 Mar 2025

Manufacturing maintenance is the backbone of industrial efficiency, ensuring machines run ...

5 Mar 2025

No one likes playing a guessing game when equipment breaks down. Yet, maintenance teams often ...

4 Mar 2025

The size of the preventive maintenance software market is discussed in millions of dollars, ...

4 Mar 2025

The organizational structure and corporate hierarchy vary from company to company. Large ...

28 Feb 2025

Maintenance procedures are essential for ensuring the longevity and reliability of machinery ...

21 Feb 2025

Sustainability is no longer just a buzzword; it's a critical component of corporate social ...

20 Feb 2025

A Computerized Maintenance Management System (CMMS) relies on accurate, well-organized data ...

18 Feb 2025

In an era where technology drives operational efficiency, Computerized Maintenance Management ...

14 Feb 2025

A Computerized Maintenance Management System (CMMS) is a key component of modern maintenance ...

13 Feb 2025

Introduction Maintenance management is the foundation of maintenance operations in industries ...

11 Feb 2025

Introduction A Computerized Maintenance Management System (CMMS) is software designed to help ...

7 Feb 2025