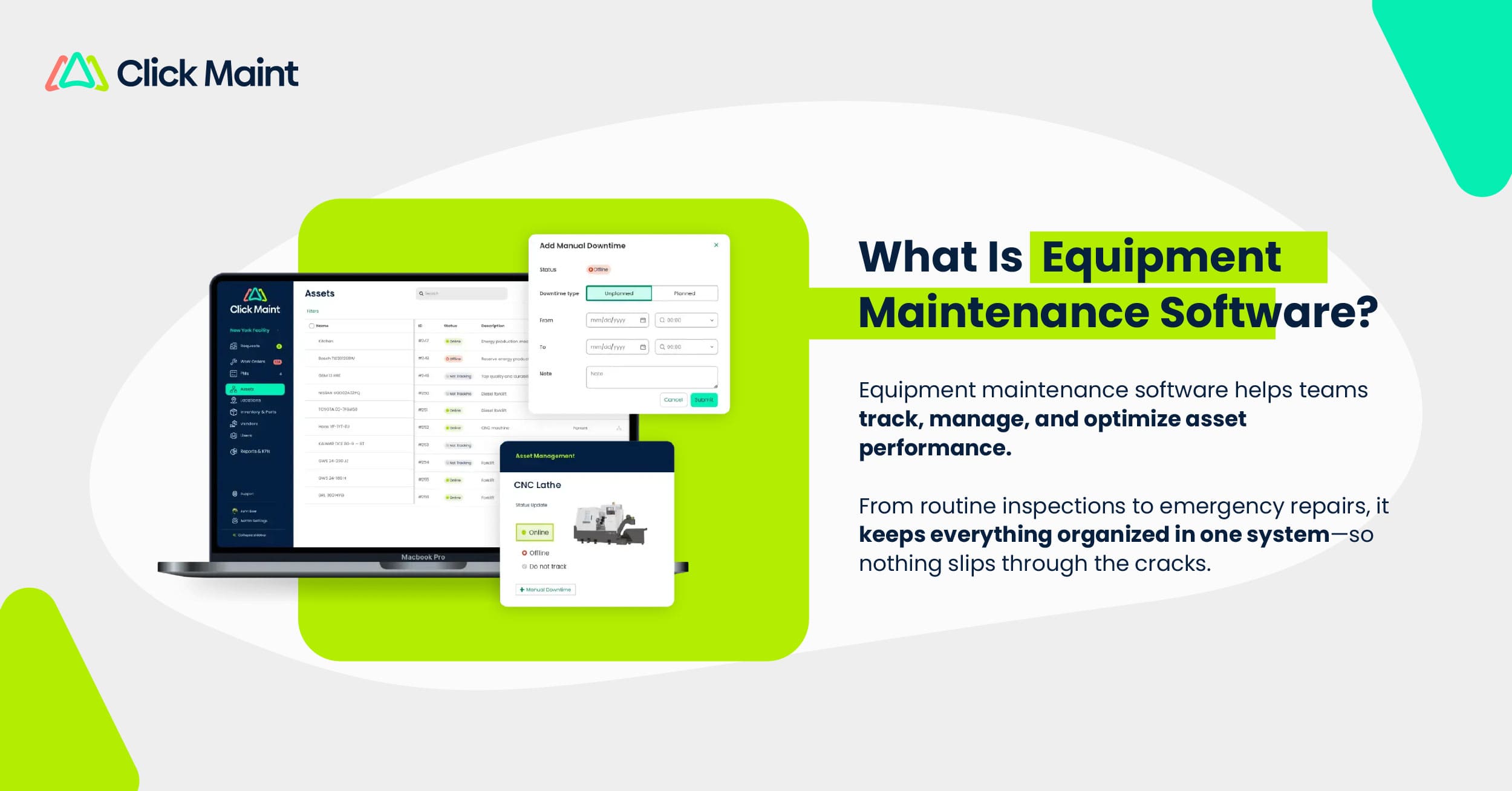

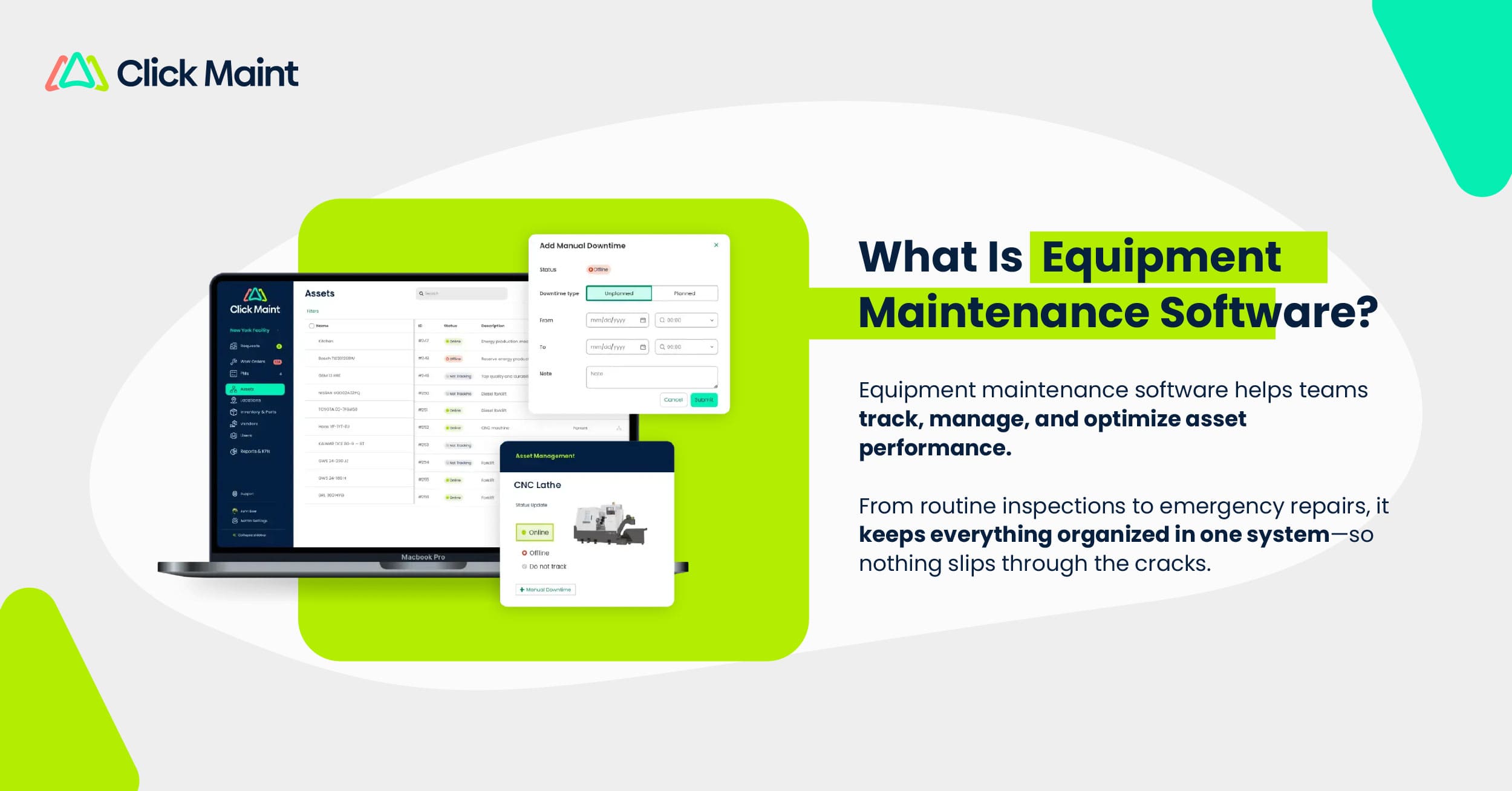

What is an Equipment Maintenance Software?

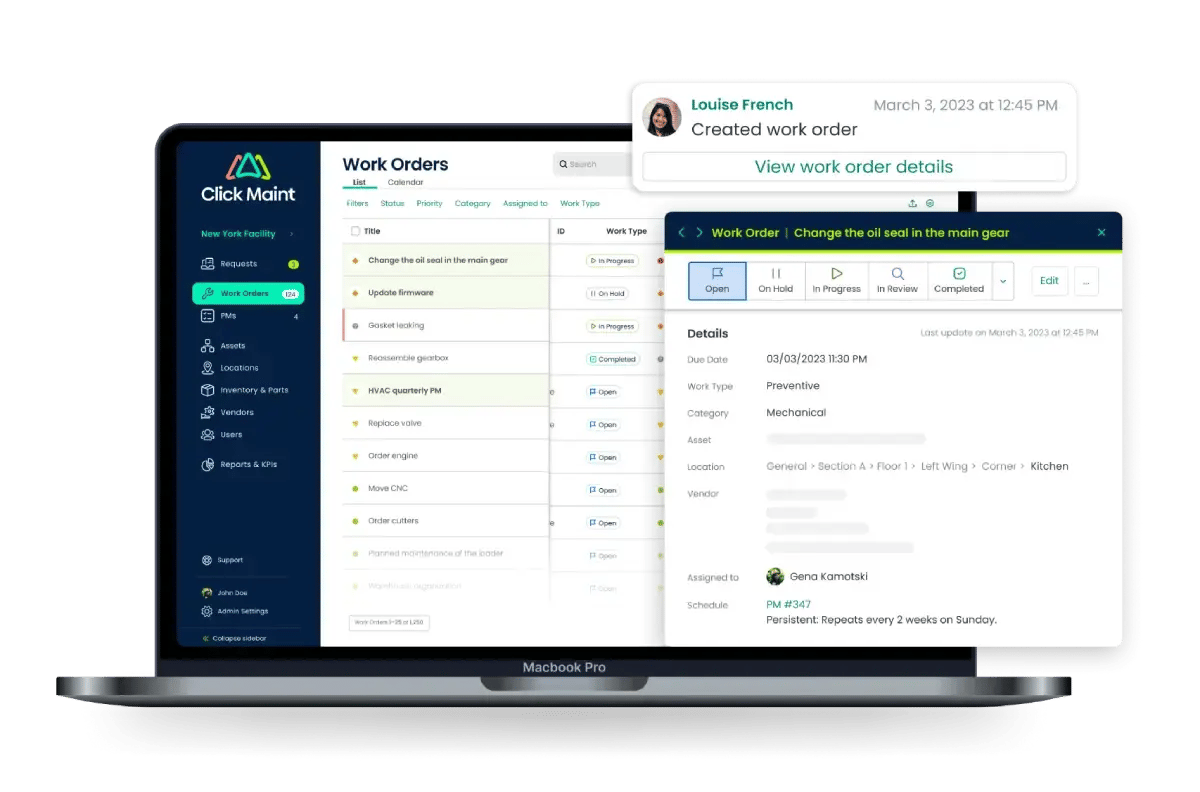

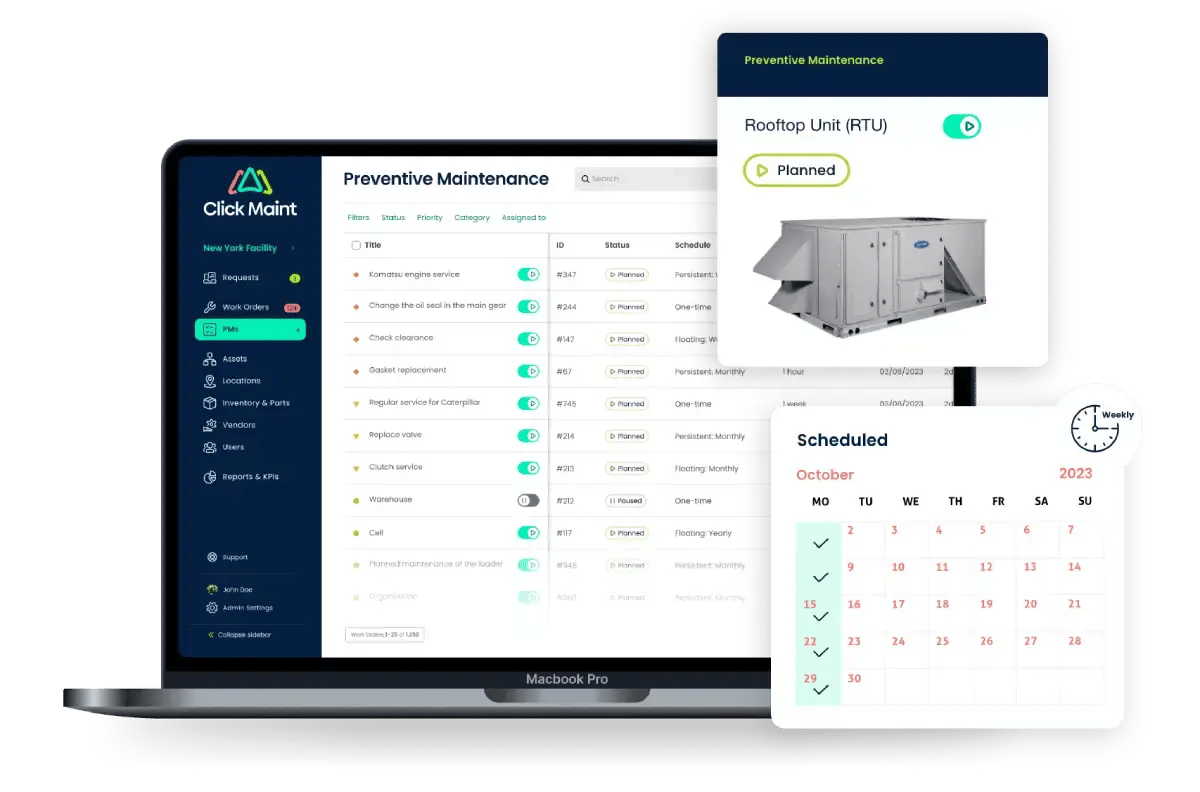

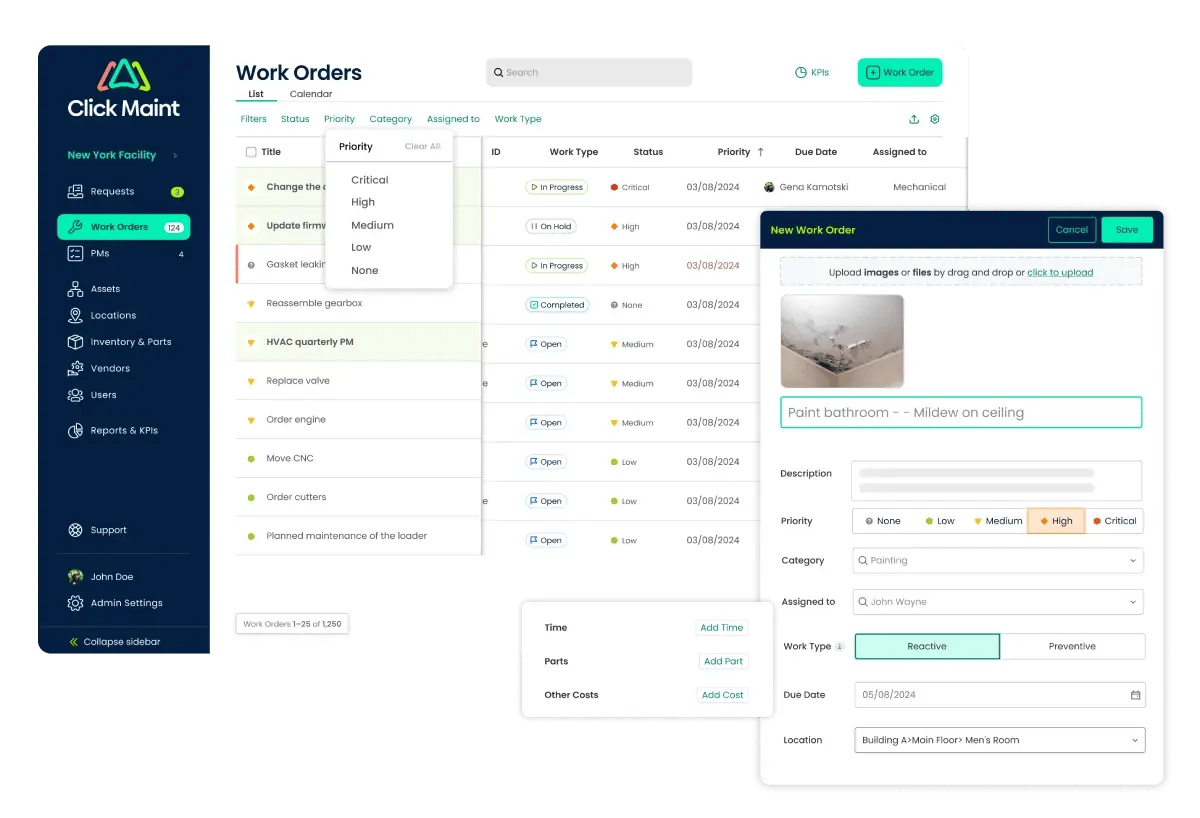

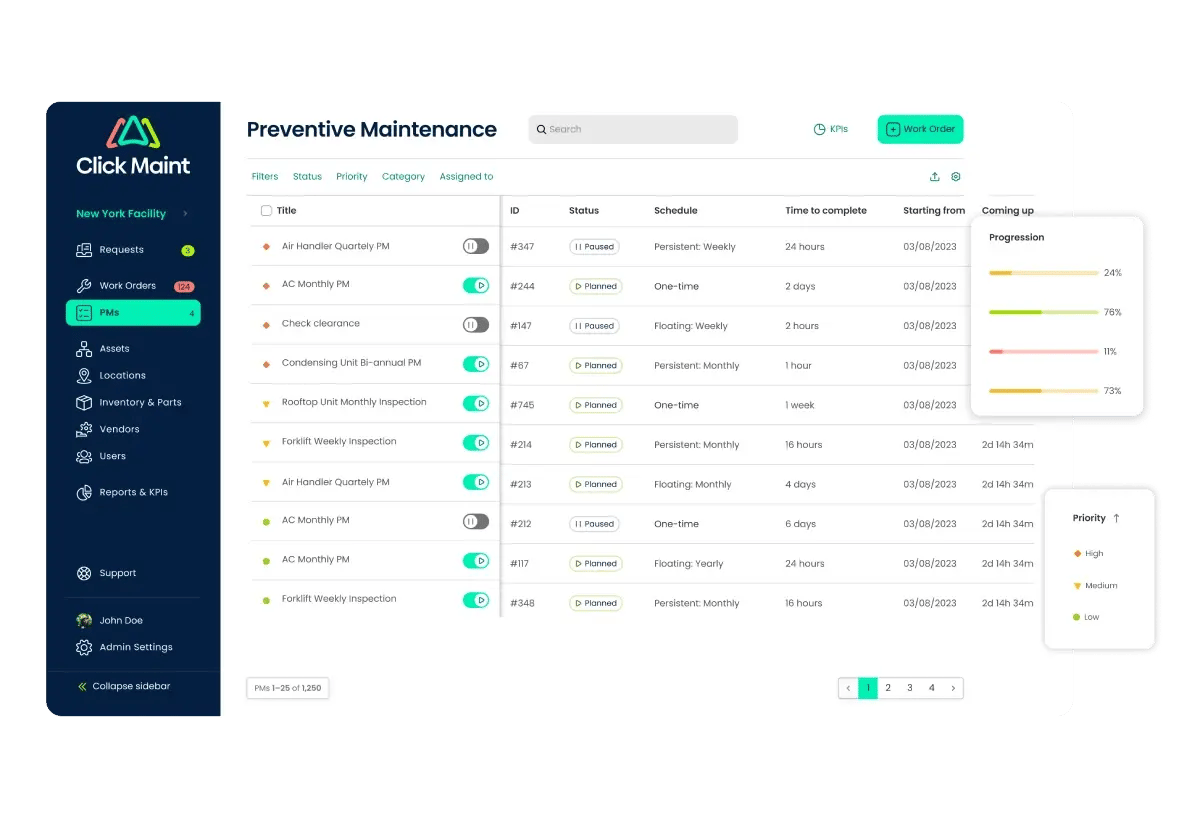

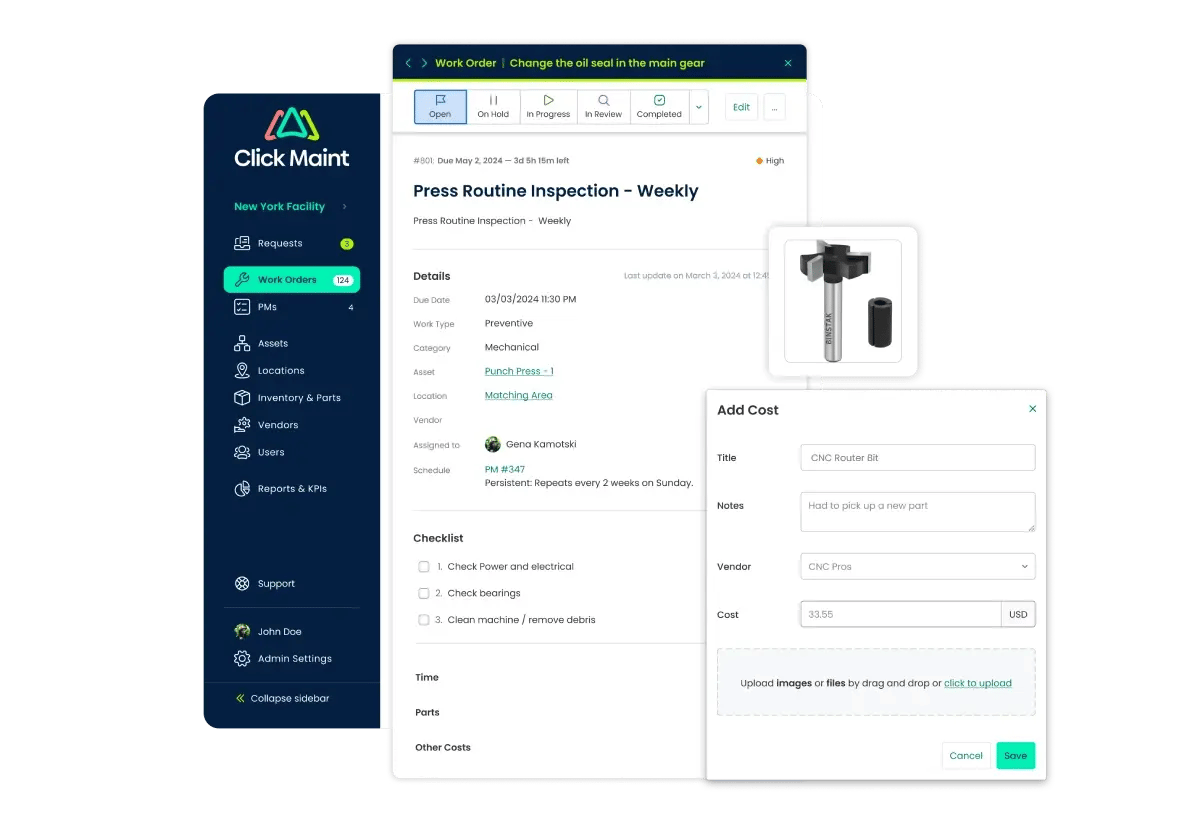

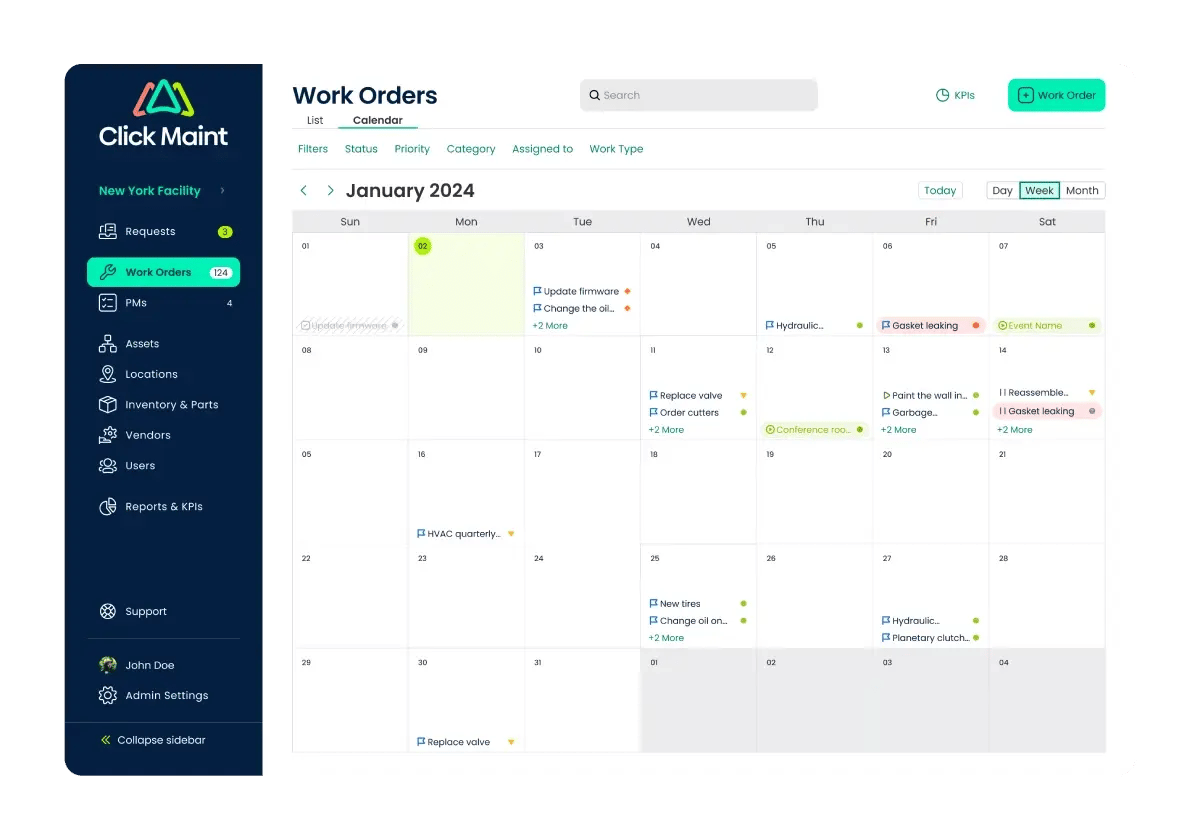

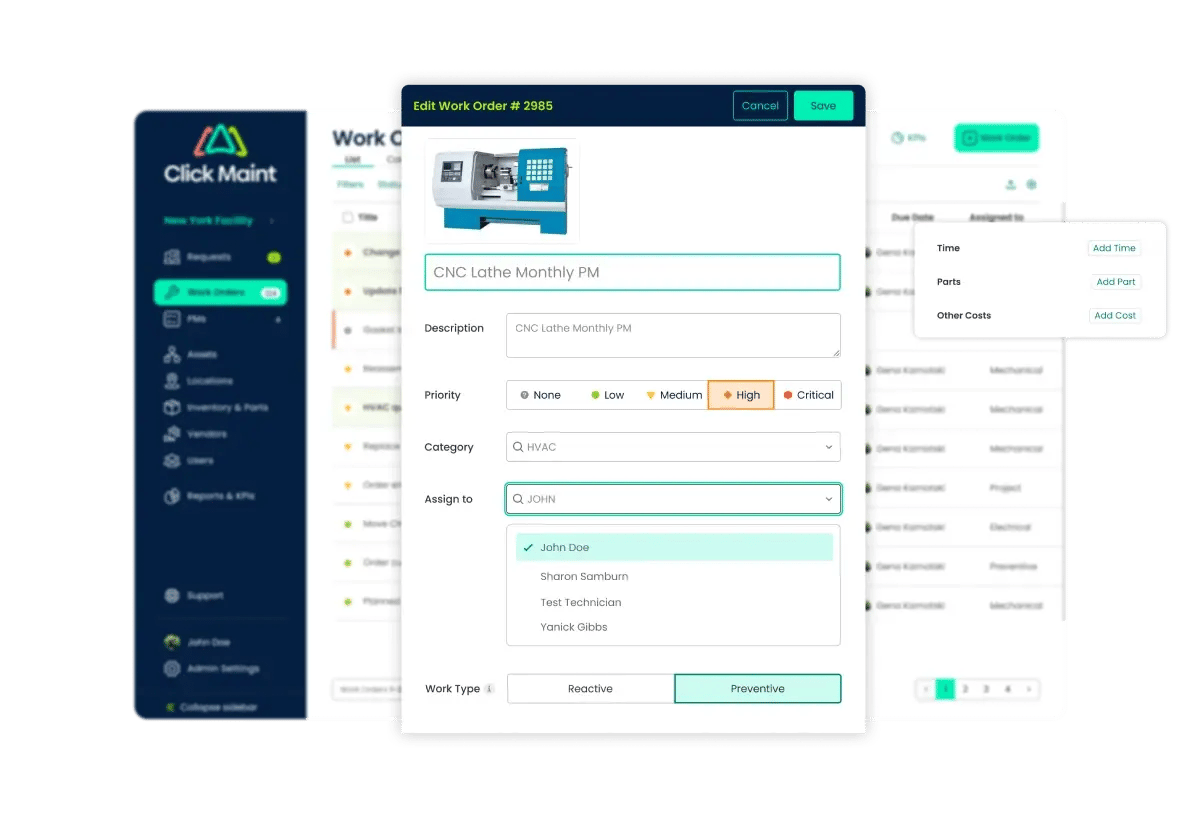

Equipment Maintenance Software is an advanced and comprehensive solution dedicated to the seamless and efficient management of maintenance procedures for various equipment. Its functionalities include the generation of work orders for proactive maintenance tasks, and the implementation of predictive maintenance scheduling.

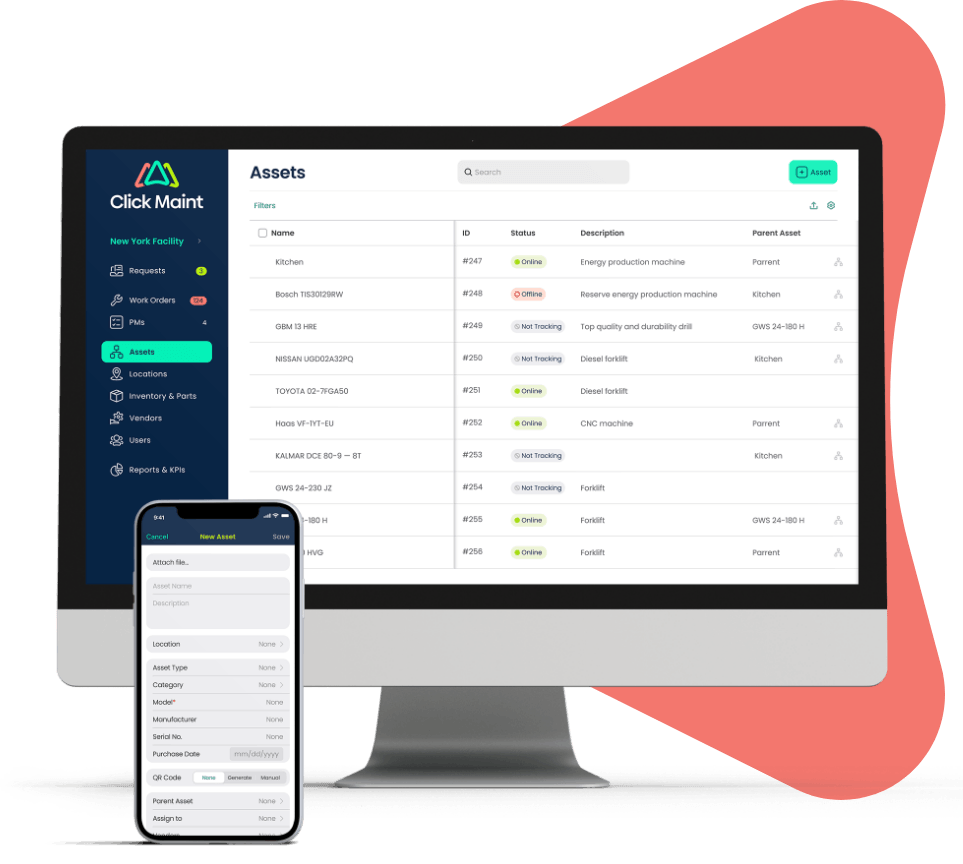

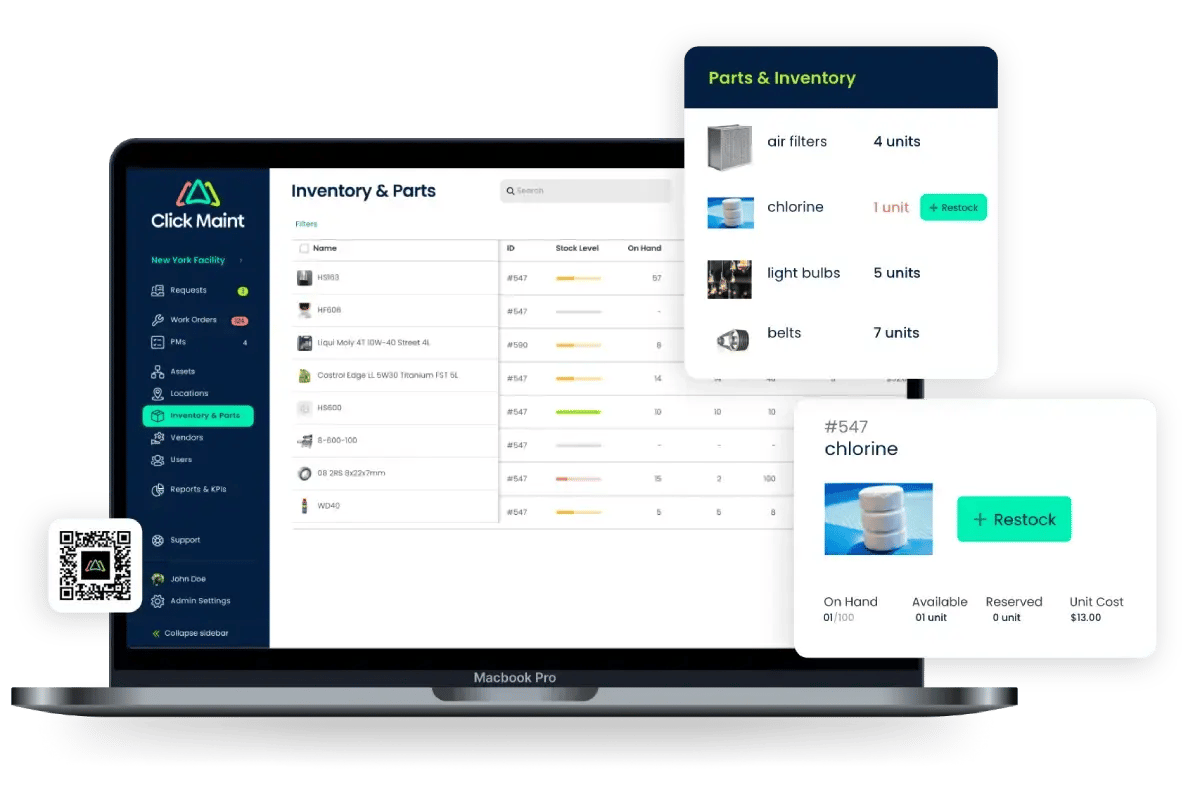

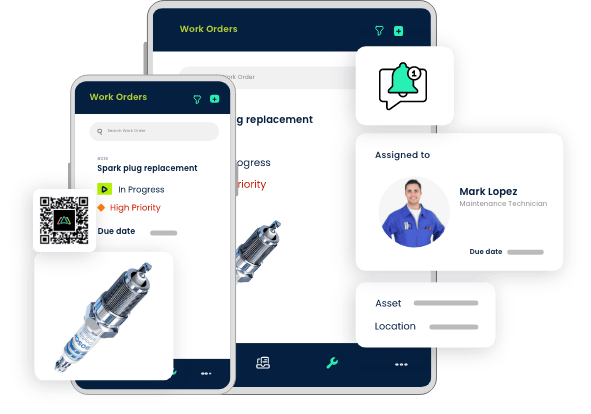

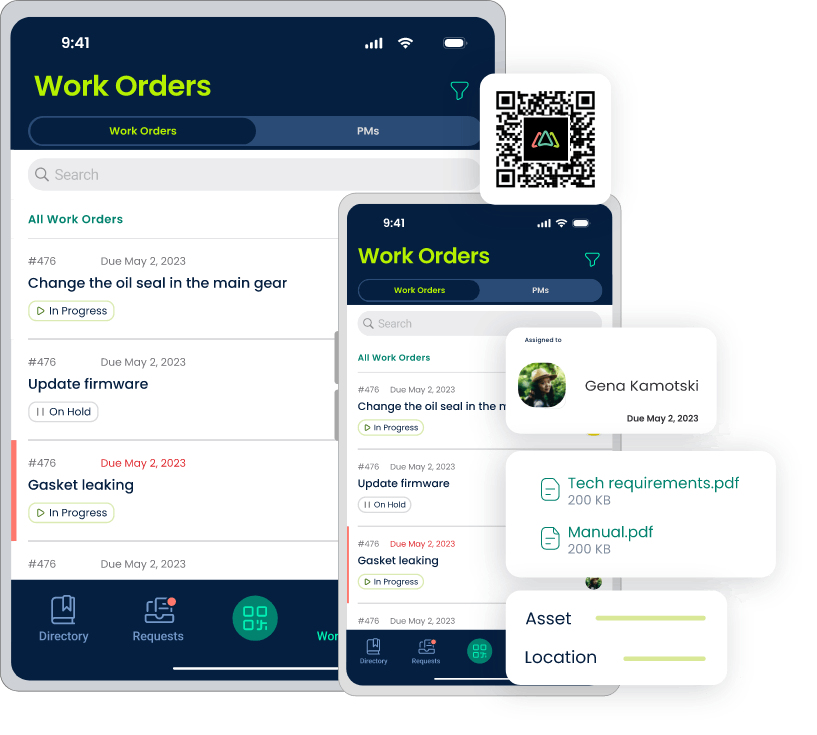

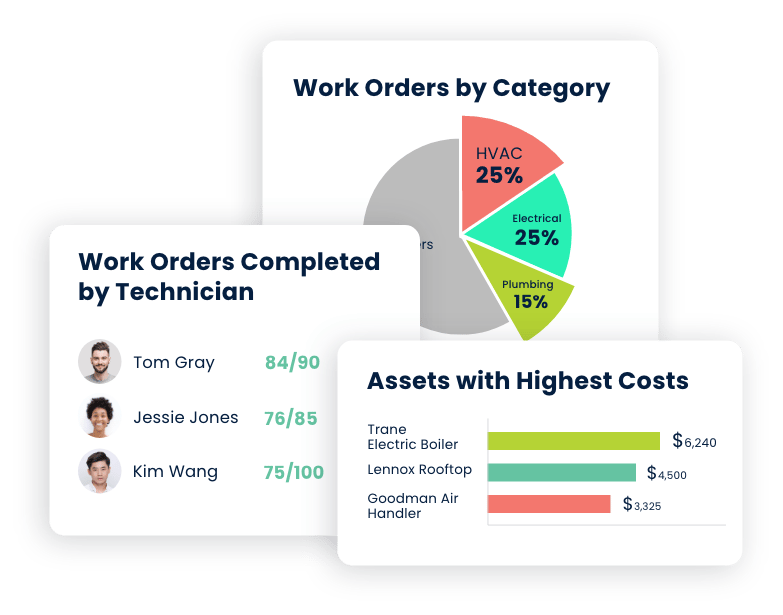

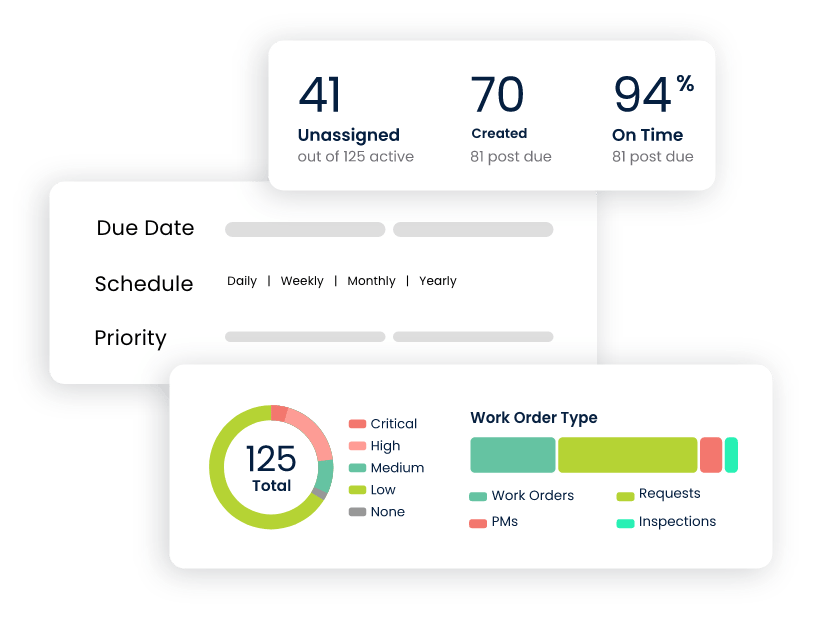

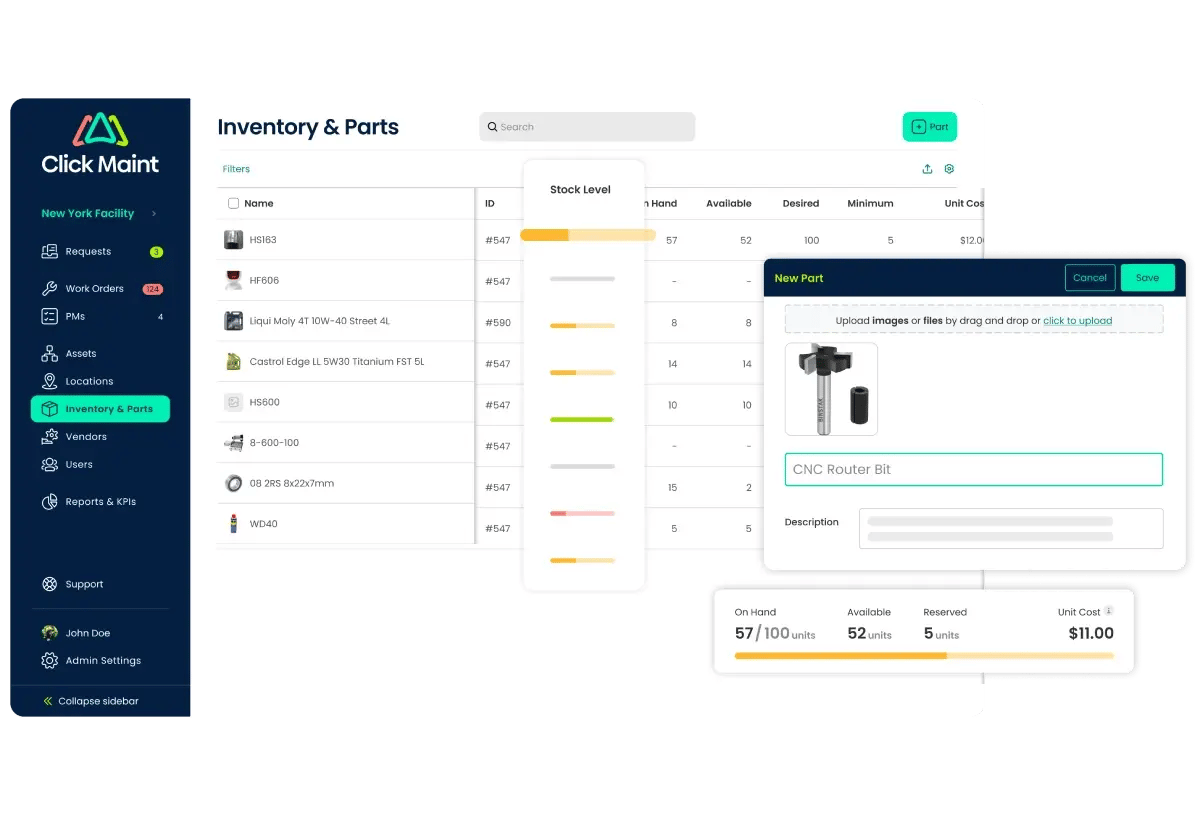

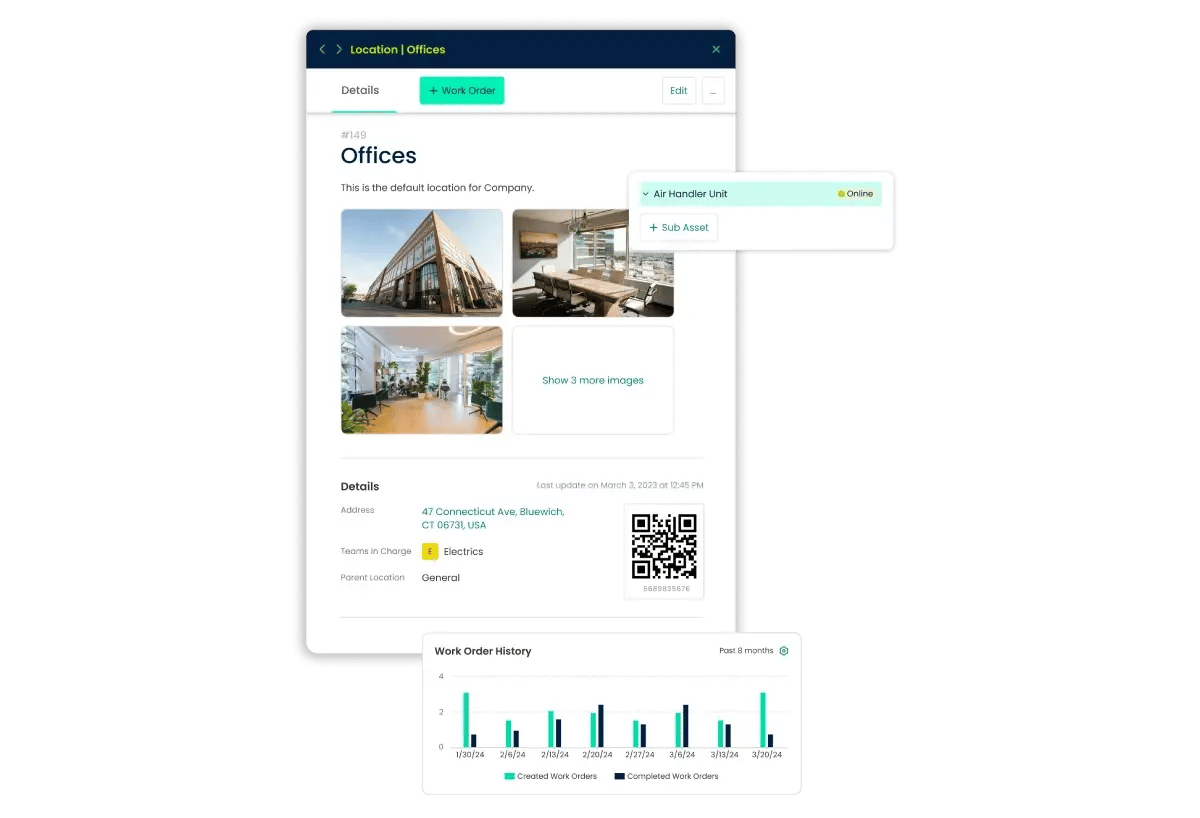

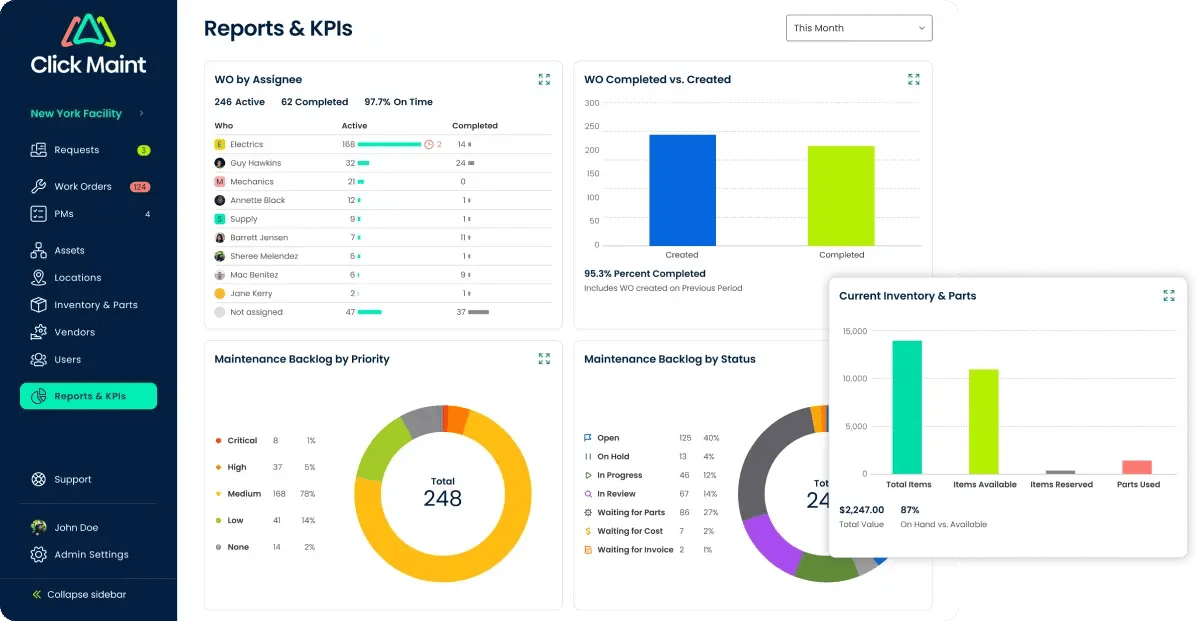

Equipment Management Software is a robust digital solution that helps with asset lifecycle management, from acquisition to disposal. Key features of the software include asset tracking for real-time monitoring, maintenance scheduling for proactive servicing, inventory management for optimized stock control, compliance management for regulatory adherence, and reporting/analytics for insightful decision-making. Equipment maintenance software benefits organizations by increasing efficiency through automation, saving costs by minimizing downtime and repair expenses, enhancing productivity with streamlined workflows, ensuring compliance with regulations, and enabling data-driven decision-making.

Purpose

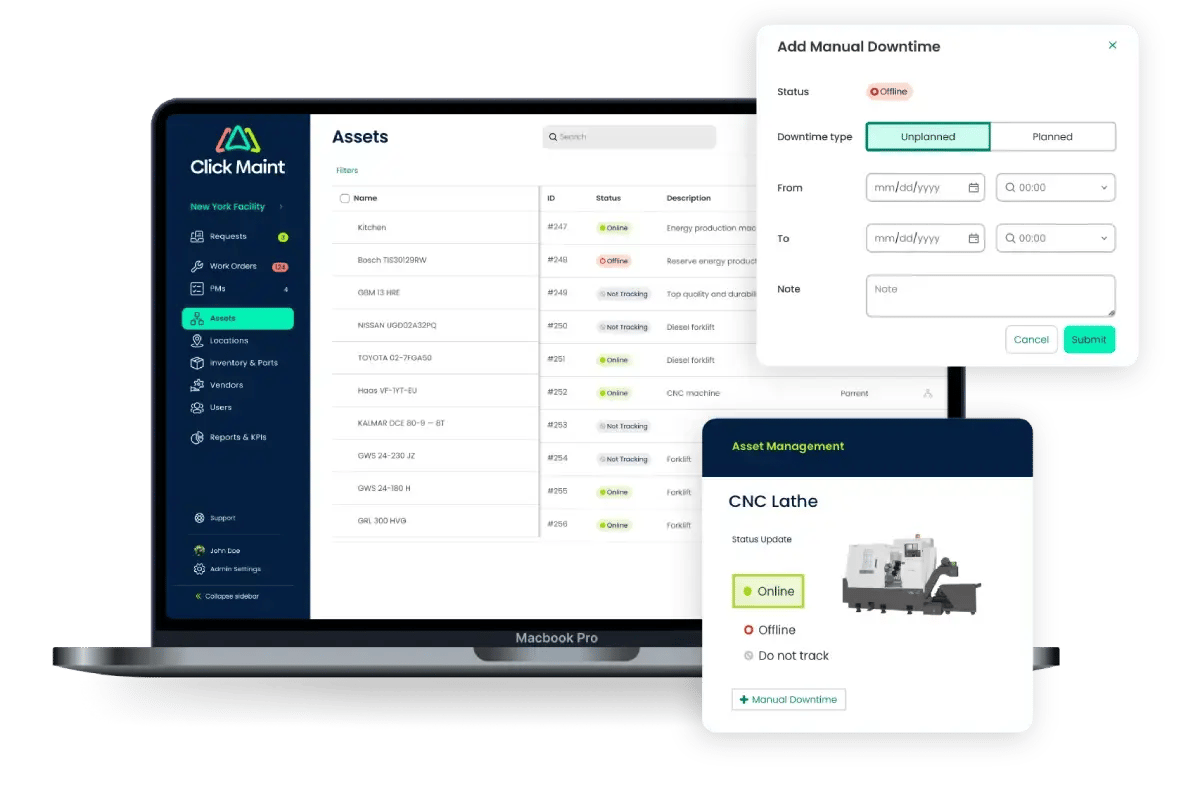

The primary purpose of Equipment Maintenance Software is to enhance the management and execution of equipment maintenance activities. It helps businesses ensure that their equipment is properly maintained, reducing the risk of breakdowns, improving equipment performance, and maximizing uptime. This software is beneficial in enhancing the longevity and productivity of machinery or equipment by actively overseeing maintenance procedures. Moreover, by tracking the real-time status of equipment, this software contributes significantly to amplifying overall operational efficacy.

Condition Monitoring- Proactive Approach to Equipment Health and Maintenance

Condition monitoring in equipment maintenance is a proactive approach that involves continuously monitoring the condition of machinery, equipment, or assets to identify any changes or deviations from normal operating conditions. By employing various techniques and technologies, maintenance teams can detect early signs of potential failures and take necessary actions to prevent breakdowns and optimize maintenance strategies.

Key Objectives of Condition Monitoring

The primary objective of condition monitoring is to detect and address equipment issues before they escalate into major failures. By regularly monitoring factors such as temperature, vibration, noise, pressure, and other relevant parameters, maintenance teams can identify abnormal patterns or trends that may indicate a problem. This enables timely intervention, such as scheduling maintenance or repairs, to minimize downtime and reduce overall maintenance costs.

Techniques and Technologies in Condition Monitoring

Condition monitoring techniques encompass a range of methods, including visual inspections, handheld device measurements, sensor or probe installations, and advanced technologies like infrared thermography, acoustic monitoring, oil analysis, and vibration analysis. These techniques generate data that is then analyzed using specialized software or algorithms to provide insights into equipment health and performance.

Benefits and Applications of Condition Monitoring

Implementing condition monitoring offers several benefits, including increased equipment reliability, extended asset lifespan, optimized maintenance schedules, and improved operational efficiency. It finds applications in various industries such as manufacturing, oil and gas, power generation, transportation, and many more, where the health and performance of critical equipment are crucial to operational success.

By leveraging condition-based maintenance, organizations can proactively manage their equipment assets, reduce the risk of unexpected failures, and ensure optimal maintenance strategies, ultimately leading to improved productivity and cost savings.

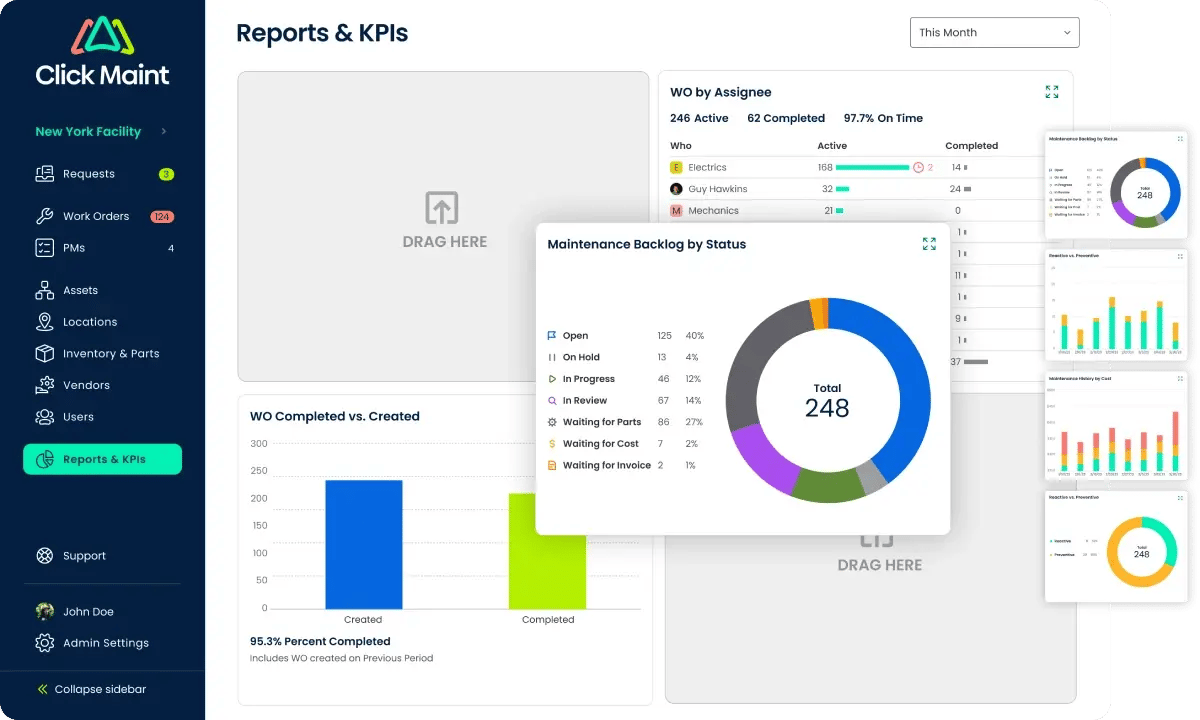

The Role of Data Analytics in Equipment Maintenance Software

By leveraging historical data and advanced analytics, organizations can gain deeper insights into their maintenance activities, uncovering patterns and trends that may not be immediately apparent. This data-driven approach allows businesses to refine their maintenance strategies, prioritizing tasks that have the greatest impact on operational efficiency.

Data analytics can also facilitate predictive maintenance by identifying patterns that precede equipment failures. By analyzing historical performance data, organizations can develop predictive models that inform maintenance schedules, ensuring that interventions occur just before issues arise. This shift from reactive to proactive maintenance not only reduces costs but also significantly enhances equipment reliability.

Can Equipment Maintenance Software Integrate with Other Systems?

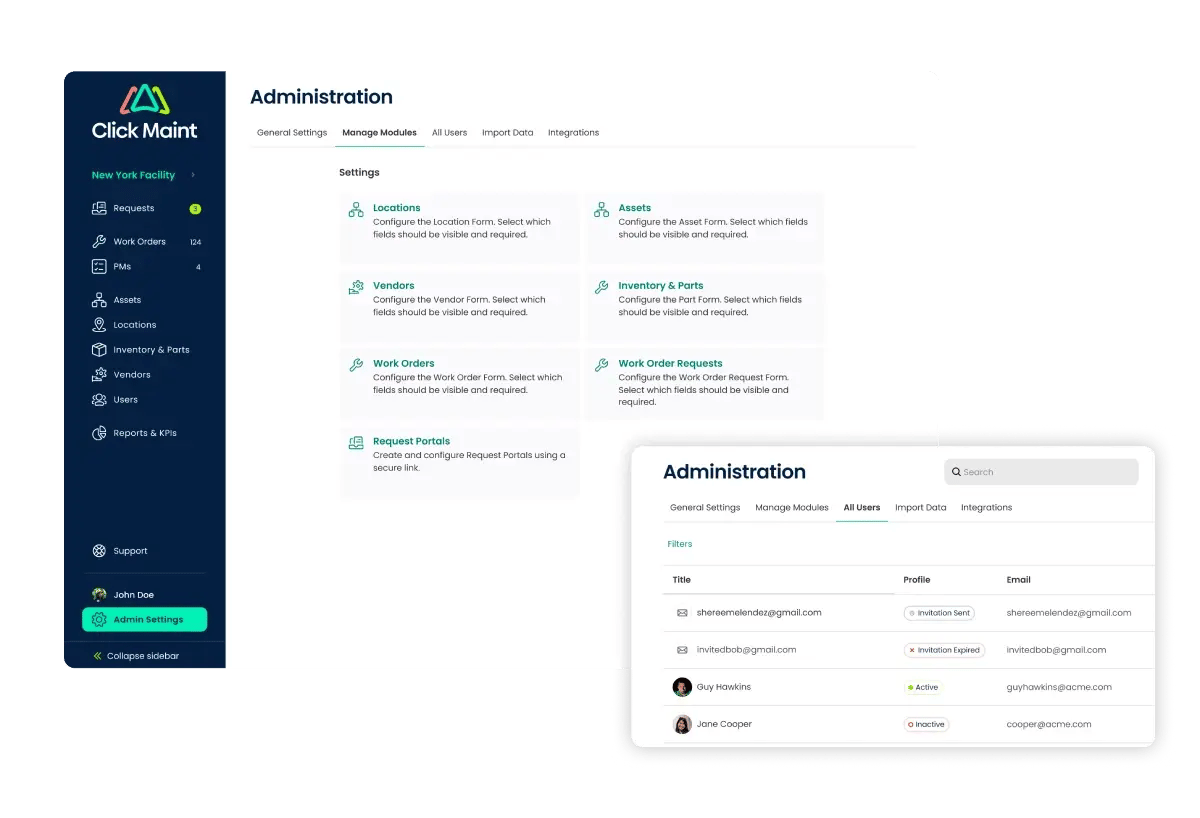

Yes, many equipment maintenance software solutions integrate with other systems such as Enterprise Resource Planning (ERP) and Inventory Management Systems. This integration creates a unified platform, enhancing data flow and operational efficiency across different departments.

Fostering User Adoption and Successful Implementation

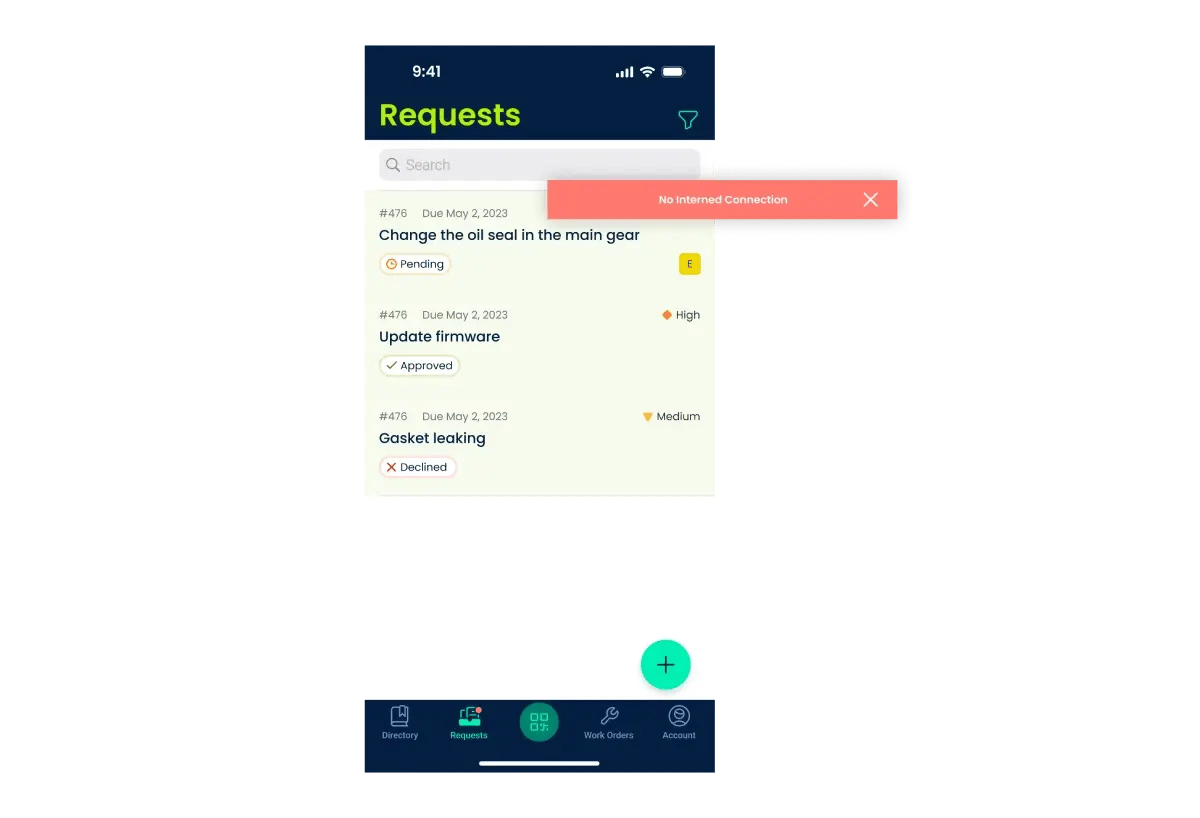

A common pitfall is underestimating the importance of educating users about the software's features and functionalities. Providing comprehensive training can help teams maximize the software's benefits, leading to improved maintenance practices and increased buy-in from stakeholders.

Additionally, ensuring that the software is user-friendly and intuitive can enhance adoption rates. Engaging employees early in the implementation process and soliciting their feedback can further streamline the transition, resulting in a smoother integration and ultimately greater operational success.

How to Choose the Right Equipment Maintenance Software?

1. Identify Needs

Assess your specific maintenance requirements and existing processes.

2. Feature Set

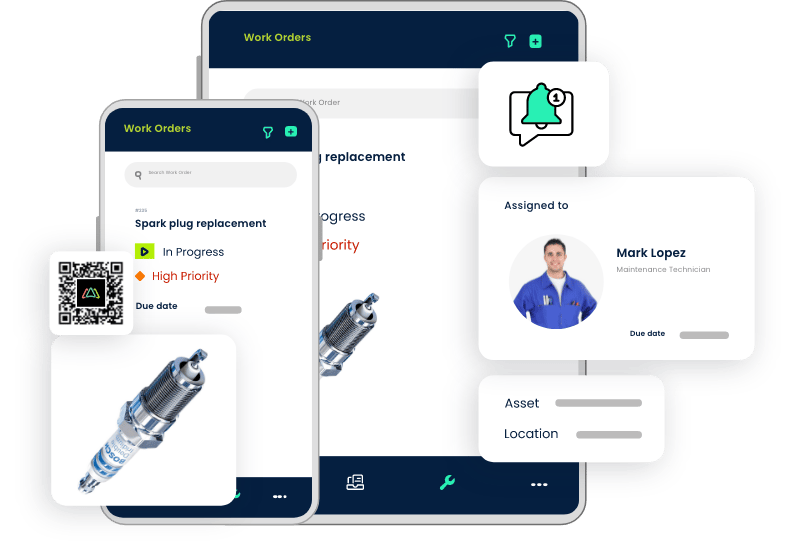

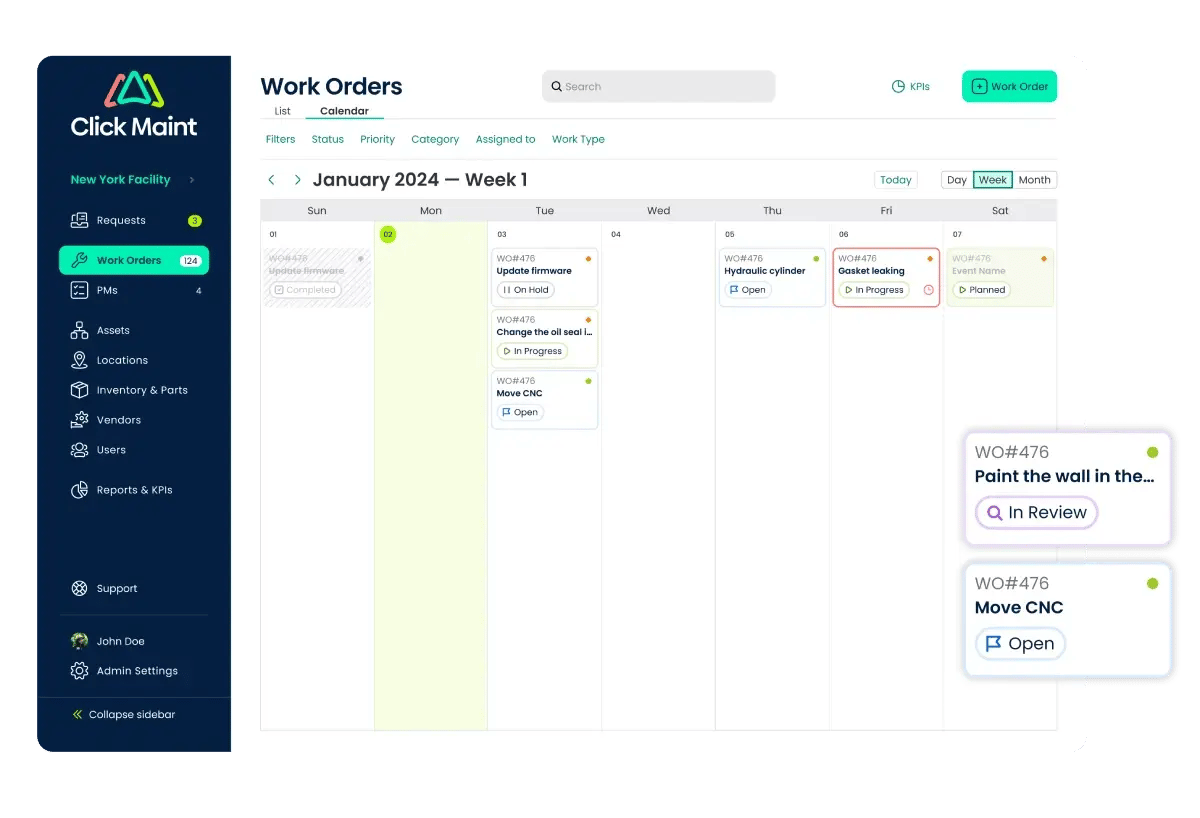

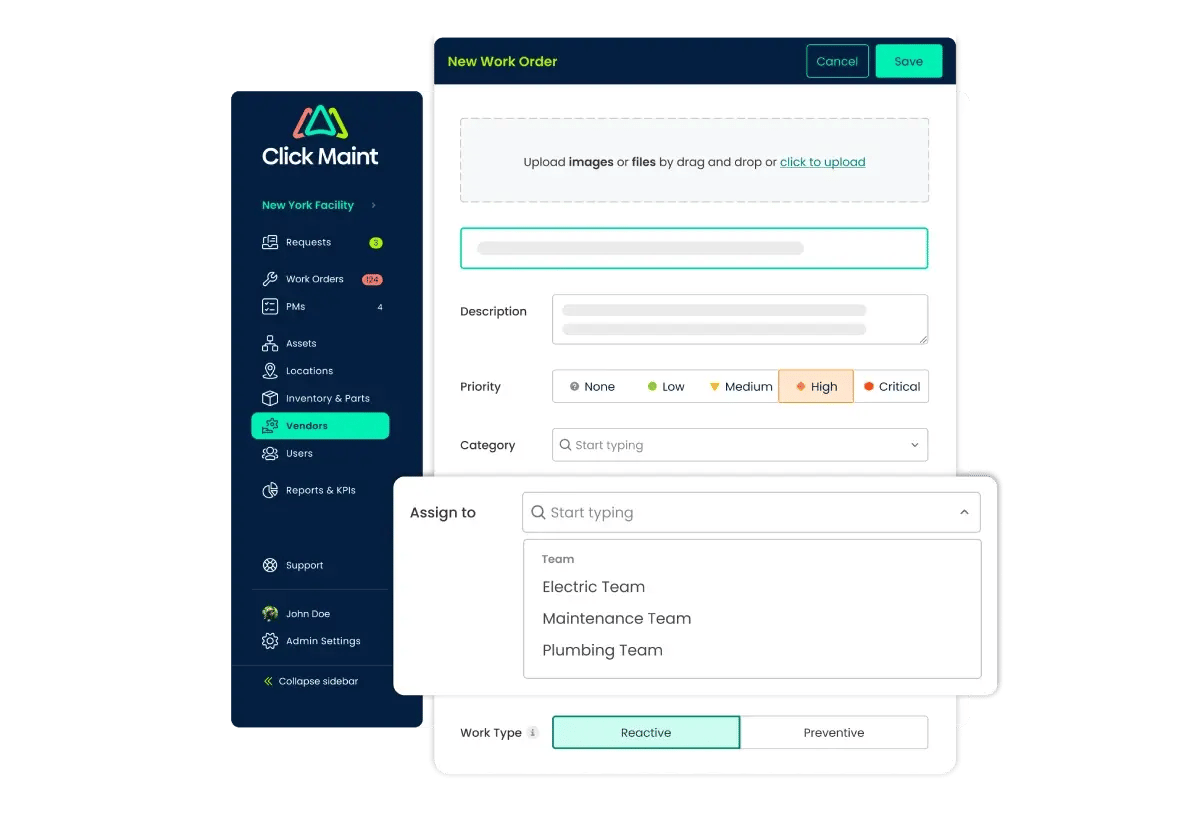

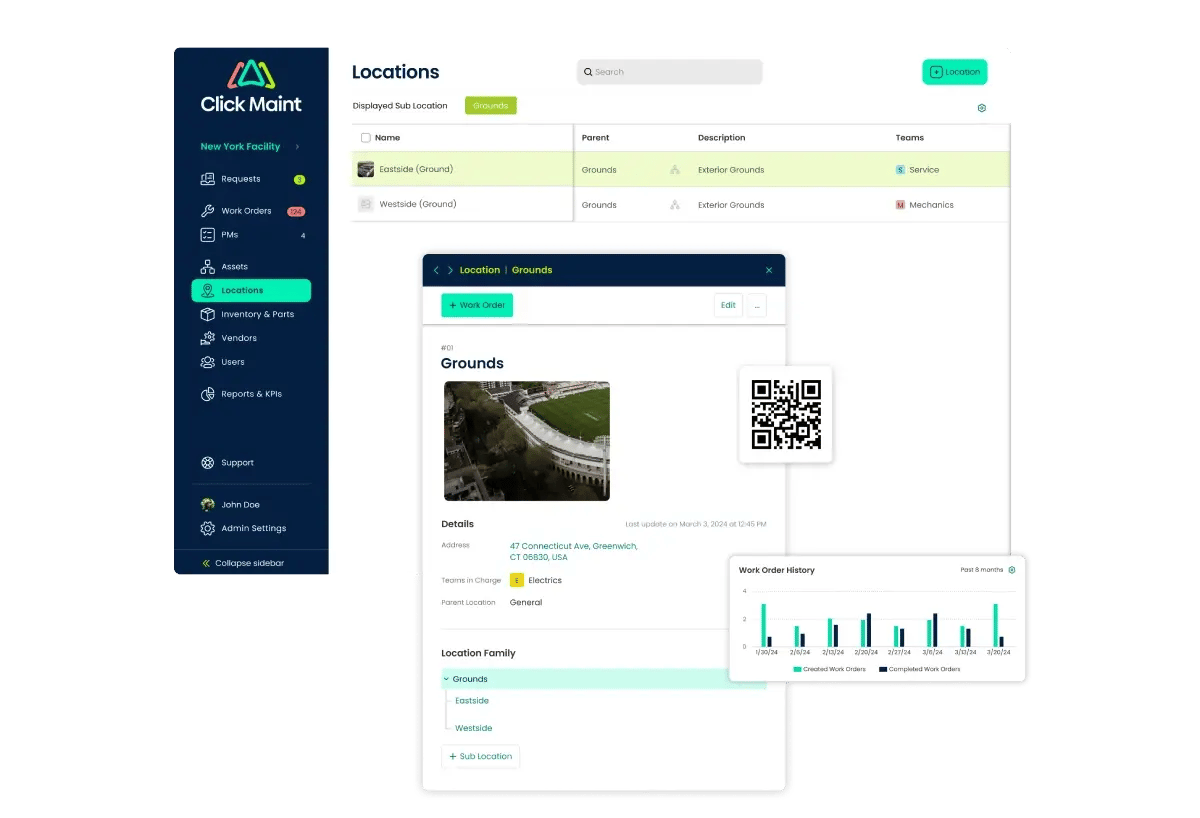

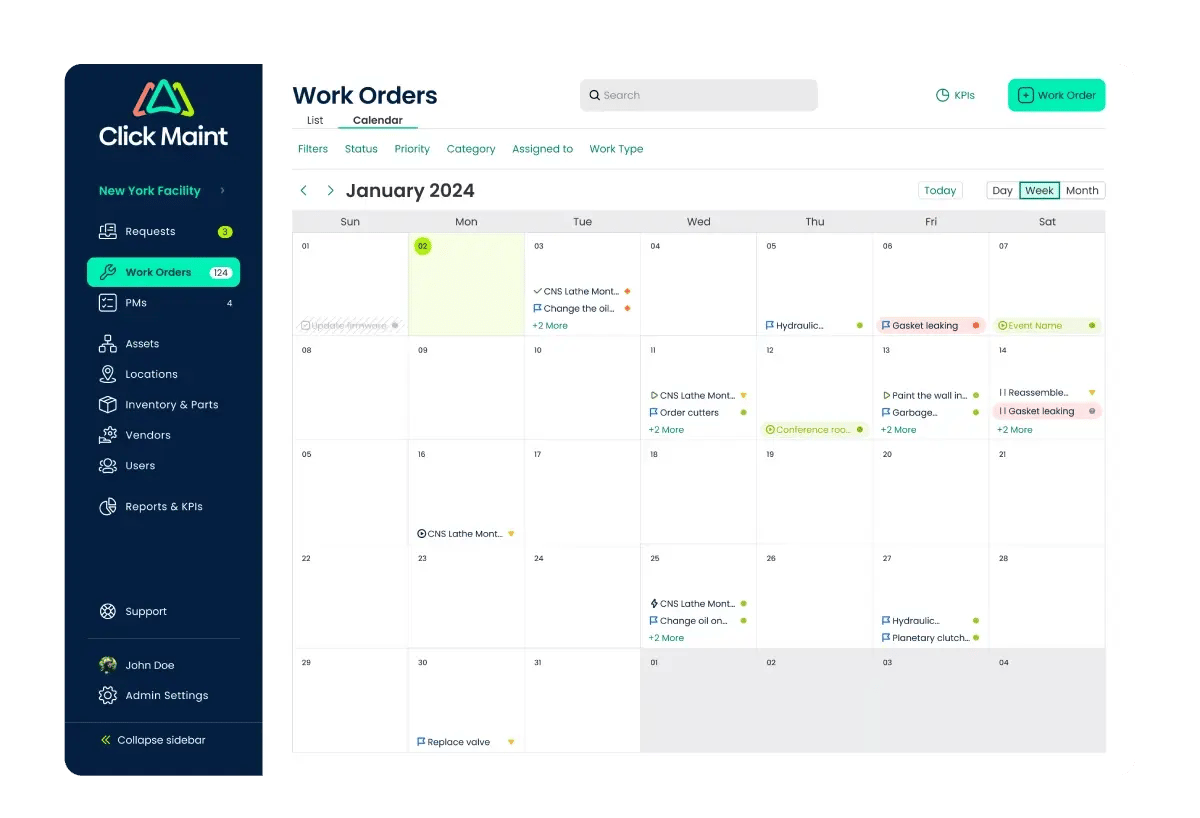

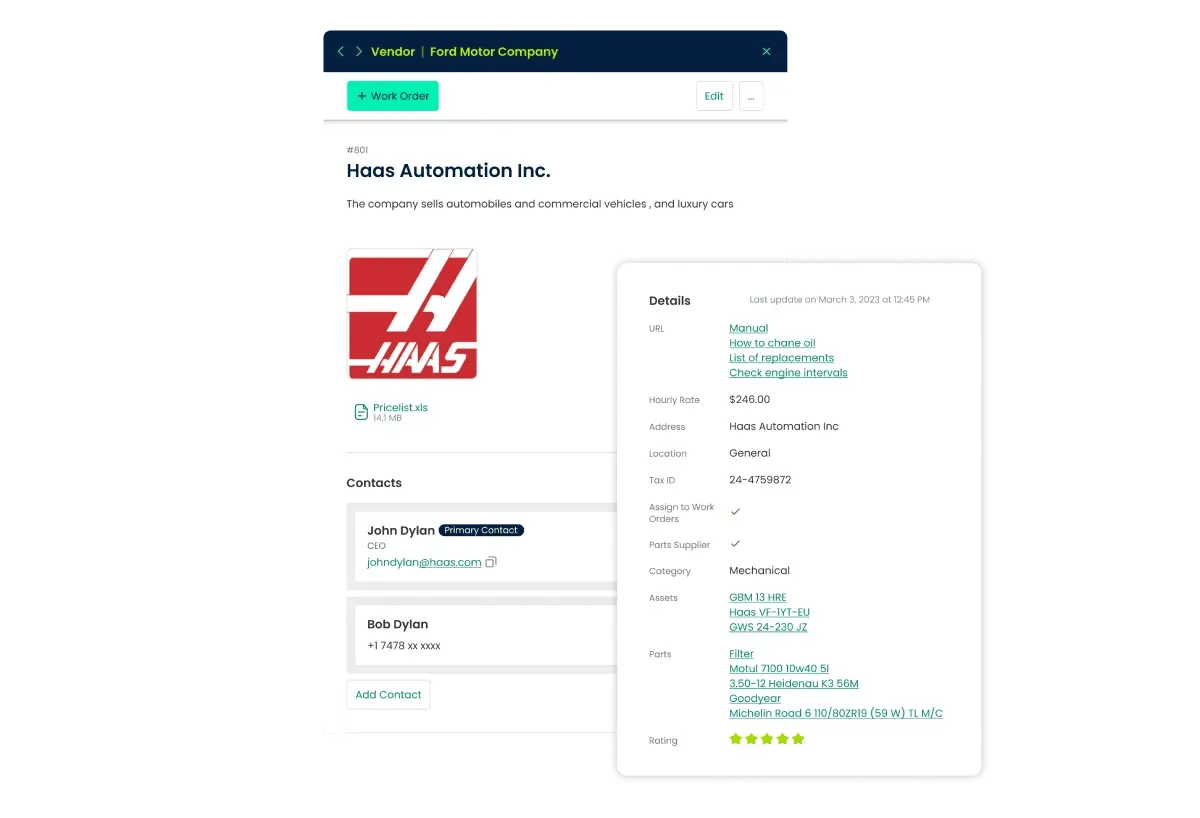

Ensure the software includes necessary features like preventive maintenance, work order management, and asset tracking.

3. User-Friendly Interface

Choose software that is easy for your team to learn and use.

4. Scalability

Ensure the software can grow with your business needs.

5. Integration Capabilities

Check if it can integrate with your existing systems.

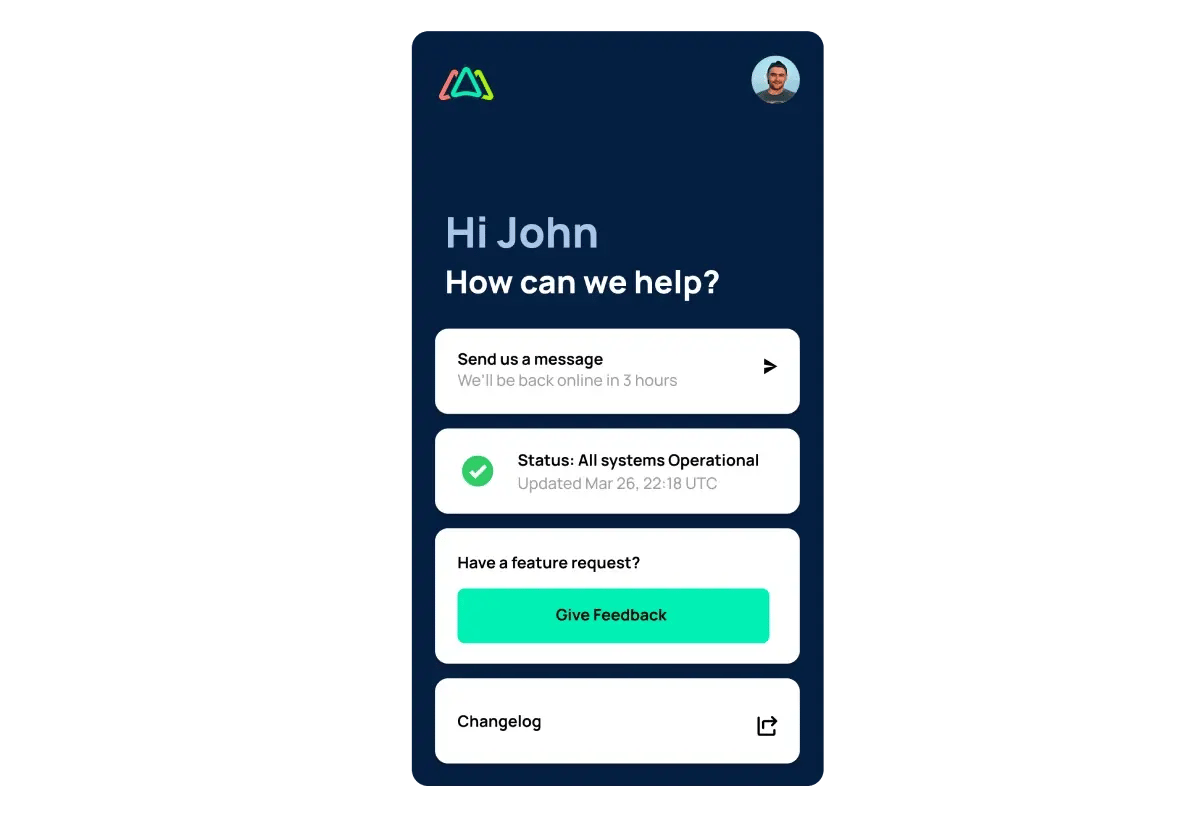

6. Vendor Support

Look for robust customer support and training options.

7. Cost

Consider the total cost of ownership, including any hidden fees.